In today's world, there are many different ways to streamline your business, and one of the most powerful tools is the factory automation system (FA). Multiple pieces of machinery help you maintain consistent high production levels, including sourcing raw materials to pack final products into boxes ready for shipment. Here are the advantages of the factory automation system.

What Do You Know about Automation in Manufacturing Process?

Manufacturing is a complex, interconnected system that requires careful monitoring to ensure that every piece is performing at its peak level. This can be difficult, especially if the company uses the traditional production mode, which heavily relies on workflow and manual operations.

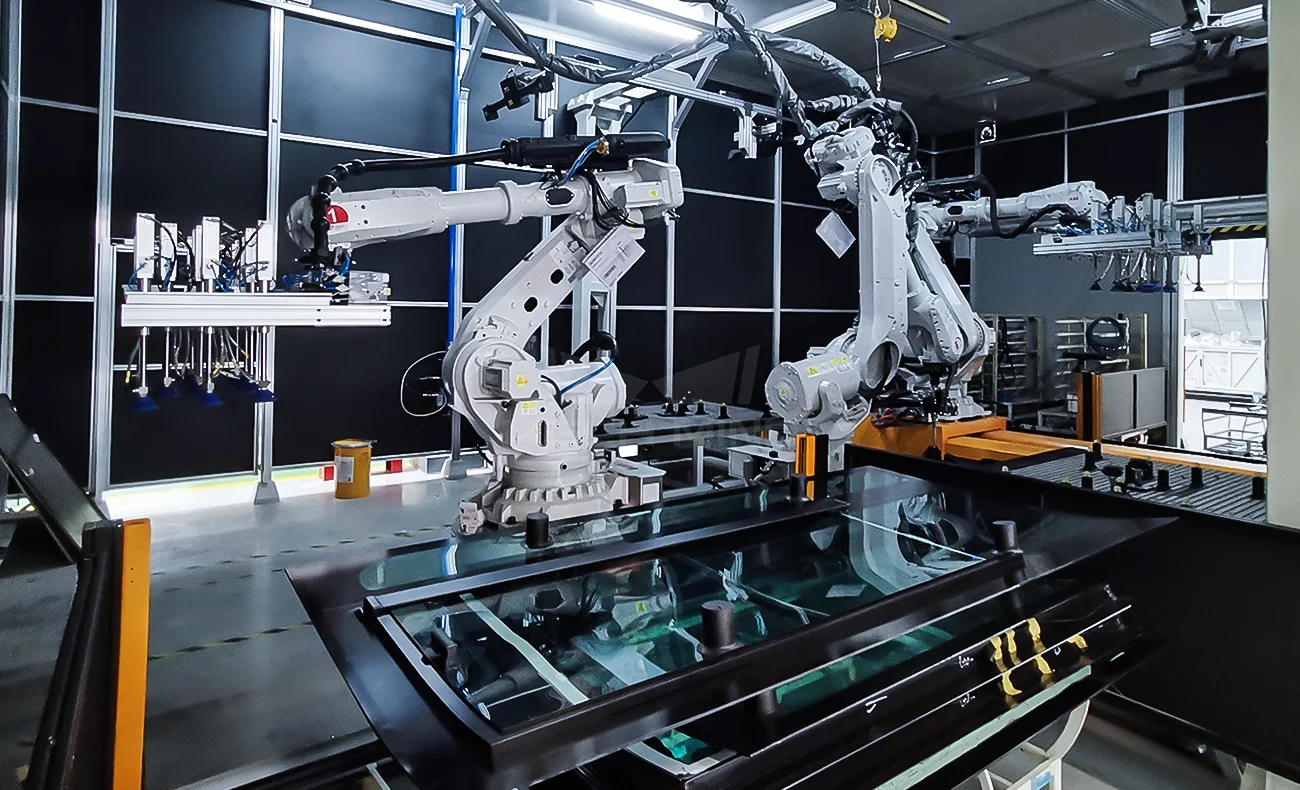

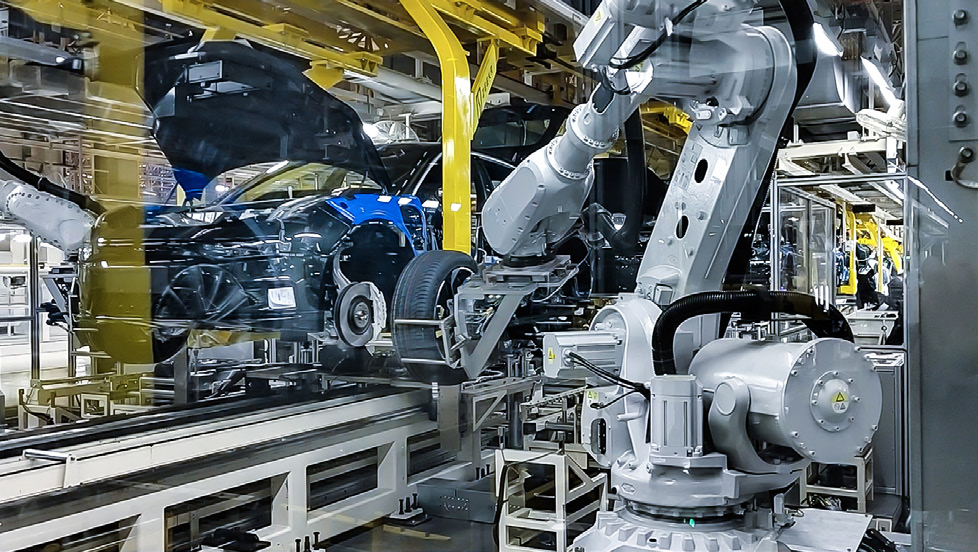

The automation system has been designed to reduce human involvement in various manufacturing processes. Robots and computers are the main tools used in this system, whose purpose is to optimize the manufacturing process. Usually, a full automation system consists of sensors, controllers, and computers that oversee machines and processes in a factory. The automation system ensures that the machines are functioning properly and efficiently while also monitoring the status of each machine at all times.

Top 5 Advantages of Building Factory Automation System

Are you wondering how your factory can benefit from the automation system? Well, here are five advantages you stand to gain from factory automation systems.

1. Increase efficiency and quality control

Factory automation systems can help increase efficiency by removing unnecessary delays and moving elements. It also improves quality control as built-in sensors detect any manufacturing errors or malfunctions within each step of an assembly line, allowing for quick fixes. One way to make your factory run at peak performance is by automating certain parts and segments of your production process with a robotic system. This allows for more consistency in your manufacturing and can help reduce errors.

2. Lower cost and higher productivity

A factory automation system makes production smoother and more efficient at its most basic level. By automating mundane tasks like scheduling and inventory tracking, companies can free up time and money to focus on higher-level activities like building new products and growing their business.

This leads to lower costs to produce each product and frees up time for employees to focus on other aspects of the business that may have been neglected while they were busy with low-level tasks.

For example, when workers spend time and energy tracking down parts or coordinating schedules, they're not focused on adding value by building new products or developing new methods for manufacturing current products. Factory automation systems can help companies stay competitive by focusing on creating new products and growing their business.

3. Improve capability of product customization and innovation

Factory automation systems also offer major opportunities for customization and innovation because they allow you to streamline efficiency in an unprecedented way. For example, by tracking data collected by all machines across your factory floor, you can identify patterns, trends, and deficiencies in real-time. Then you can act quickly to adjust your production schedule or re-route materials as needed—and never miss a beat when it comes to production because you don't have any bottlenecks or delays.

4. Reduce waste and protect environment

The amount of waste produced by a factory isn't just an environmental concern; it's also financial. A manufacturing plant that produces excess waste is losing money because it's paying for the raw materials and energy that go into those products that are never used. Industrial automation can help companies recover those costs by collecting data on the precise amount of raw materials used in each production run, allowing for more effective inventory management and precise planning for future orders. Additionally, this data makes it possible to track the impact of each manufacturing process on product quality and safety, allowing companies to identify possible issues with their suppliers before they become a major problem.

With industrial automation software that allows factories to run at maximum efficiency, there are no excuses not to reduce waste while providing employees with a safe and comfortable working environment.

5. Increase workplace safety

One of the top benefits a factory automation system offers is reducing workplace accidents, including injuries and fatalities. The controlled environment that a computer-operated machine provides can keep workers safe from dangerous situations. Machines equipped with 3D sensing vision are programmed to stop when they sense an object in their path—which again helps reduce employee injuries due to workplace accidents.

More Flexible Automated Process with AI + 3D Vision Solutions

Modern factories are often overwhelmed by large amounts of data, increased production complexities, and more complex product designs. As a result, factory management systems are often built around traditional, rigid processes that cannot adapt to changing conditions and demands.

The AI+3D solution integrates various machines into a single system, allowing for a more flexible production process. Mech-Mind provides such intelligent robotic solutions involving the systems necessary for automated processes like Mech-Eye Industrial 3D Camera and Mech-Vision Machine Vision Software. It helps manufacturers better manage their business by collecting, organizing, analyzing, and visualizing data from various sources in real-time. Data is also made available for immediate action and decision-making.

Wrapping Up

If you have a factory, you need to have an efficient factory automation system in place. This can help your productivity and bring many other benefits that you may not be aware of until you try it out on your own.