The existence of robotic vision systems has significantly contributed to expanding different possibilities for industrial robots, especially regarding their development and capabilities. Before, robots were only limited to handling simple tasks with little to no variations. However, as time passes, they have emerged to become more adaptable and intelligent with the help of vision guidance. Because of this, 2d vs 3d vision systems have been becoming major assets in various industries to help minimize human effort, all while ensuring work efficiency and productivity.

Regarding these matters, 2d vs 3d vision is among the most commonly talked about. Determining what 2d vision vs 3d vision both offer will help you understand what they are, especially the entire process that goes around both 2d and 3d vision systems and how they work.

For this reason, here is some necessary information that highlights the distinction between the two so you can be guided in selecting which 2d or 3d vision best fits your application needs.

Traditional 2D Vision System

Compared to three-dimensional vision systems, two-dimensional robotic vision has existed for much longer. They were the first to be developed in a cost-effective yet sophisticated way. Apart from that, these vision systems are also widely used within the industrial automation industry and are compatible with most software packages. Because of this, they are considered the default technology used for the majority of machine vision applications.

However, despite being a great tool for a wide number of applications, it has fundamental problems that cannot be ignored.

2D Vision System: Limitations and Applications

One main advantage of 2D robotic vision systems is they are less expensive to integrate compared to those of 3D systems, but they're also user-friendly and reliable. With 2D robotic vision, a camera usually processes an object's image across x and y planes by comparing variations in contrast. Since these systems only operate on two-dimensional feedback, they are more suitable for simple applications.

Limitations of 2D Vision:

① Limited Flexibility: You can get clear identification of flat parts only when they are separately arranged in a plane. You can use a shaker table to achieve it. Howsoever, it also increases the hardware and integration costs.

② No 3D-Shaped Parts: They can look very different at different angles and orientations. So it is hard to know what a 3D part may look like merely from a flat surface.

③ No Depth Information: 2D vision systems can only operate on 2 dimensional (x, y planes) feedback. You’re not handling any height information with 2D vision systems.

④ High Light Dependency: The shadows caused by changing lighting conditions give objects new contours. This only breeds possible errors in your applications.

If you're seeking to automate more complex applications, a 2D vision system is not recommendable; instead, it's better to opt for 3D machine vision.

3D Vision System

While 3D machine visions are still fairly new to the industrial robot industry, they are nonetheless carving a significant impression by expanding the breadth of robotic applications to address more advanced tasks that 2D vision systems usually can't do. 2D machine visions only cater to simple processes; however, 3D vision now makes it possible to capture the complete dimensional data for a particular object.

This makes it especially useful for logistics and manufacturing settings and other challenging industrial environments especially where specific dimensions are considered to be essential. Most importantly, 3D machine vision systems, unlike 2D, are immune to the different factors that affect 2D systems, such as distance, contrast, and lighting.

3D Vision Systems: Applications and Advantages

Compared to two-dimensional processing of images, utilizing 3D vision systems can be more intensive when it comes to software, time, and processor. However, it accounts for it largely with its 3D algorithms, multi-core processors, and various software tools that make them much more capable of keeping up with various industries' production lines.

Because of this now-extended capability, 3D vision systems are now being applied to a wide range of tasks that 2D vision cannot do. Among these are:

• High-precision assembly

• Volume, flatness, thickness, and height measurement

• Surface tracking and robot guidance

• Digitization and object scanning

• Random bin picking

• Mixed depalletizing and palletizing

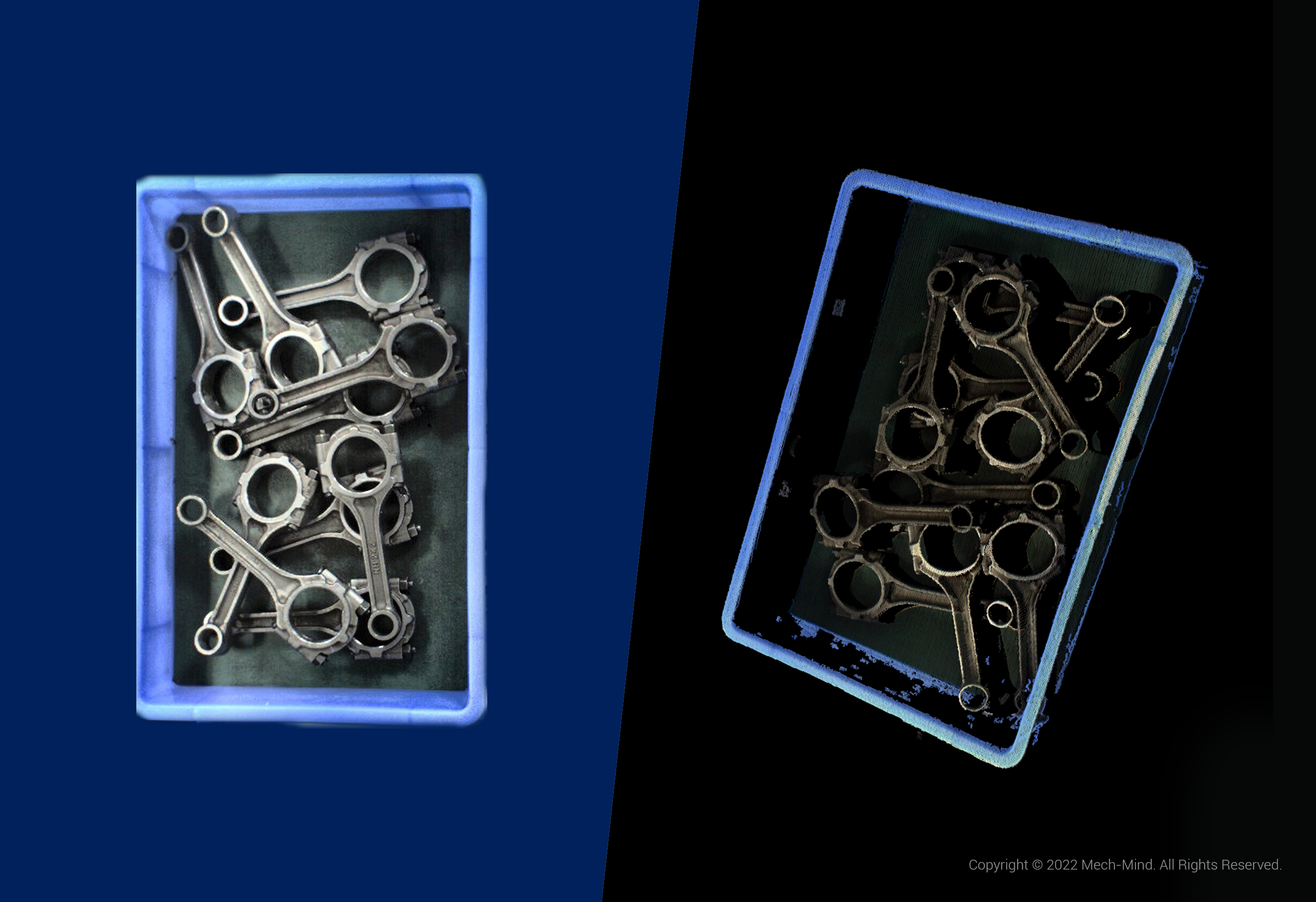

Random bin picking, for instance, is still considered a difficult test for various vision systems due to how the robot must learn how to best grip apart. Not only that, but it also needs to consider size differences and various measurements. For this reason, the robot must see the part clearly.

3D vision processes all this information in real-time with utmost precision and accuracy, despite whether or not it encounters a change in scene dynamics or if the parts are dark, reflective, shiny, or light-absorbing. It does all this efficiently regardless of the item's orientation or position in the bin.

Summary

While 2D vision systems are more traditional, reliable, and simple to operate, 3D vision systems offer exceptional and great manufacturing flexibility and adaptability to different changes on the go. Random bin picking, measurement, assembly, inspection, quality control, etc. can be best suitable for 3D systems. However, it's still important that you determine which 2D vs 3D vision systems fits your needs best so you'll be able to arrive at a decision that helps you maximize what each can offer. In the end, it all ultimately depends on the speed of measurement, the level of accuracy you require, and whether your object is moving or fixed.

Mech-Mind Products

For your complex and advanced application demands, Mech-Mind provides efficient solutions that include Mech-Eye industrial 3D cameras, Mech-Vision machine vision software, Mech-Viz intelligent robot programming environment integrating motion planning and deep-learning algorithms that are useful for picking up items with utmost precision.

Mech-Eye industrial 3D cameras

Mech-Mind believes that everyone deserves a hassle-free, productive, and efficient work environment, which is why we offer products that are cost-effective, highly intelligent, and easy to operate, so operators can minimize human effort while maximizing all the convenience.