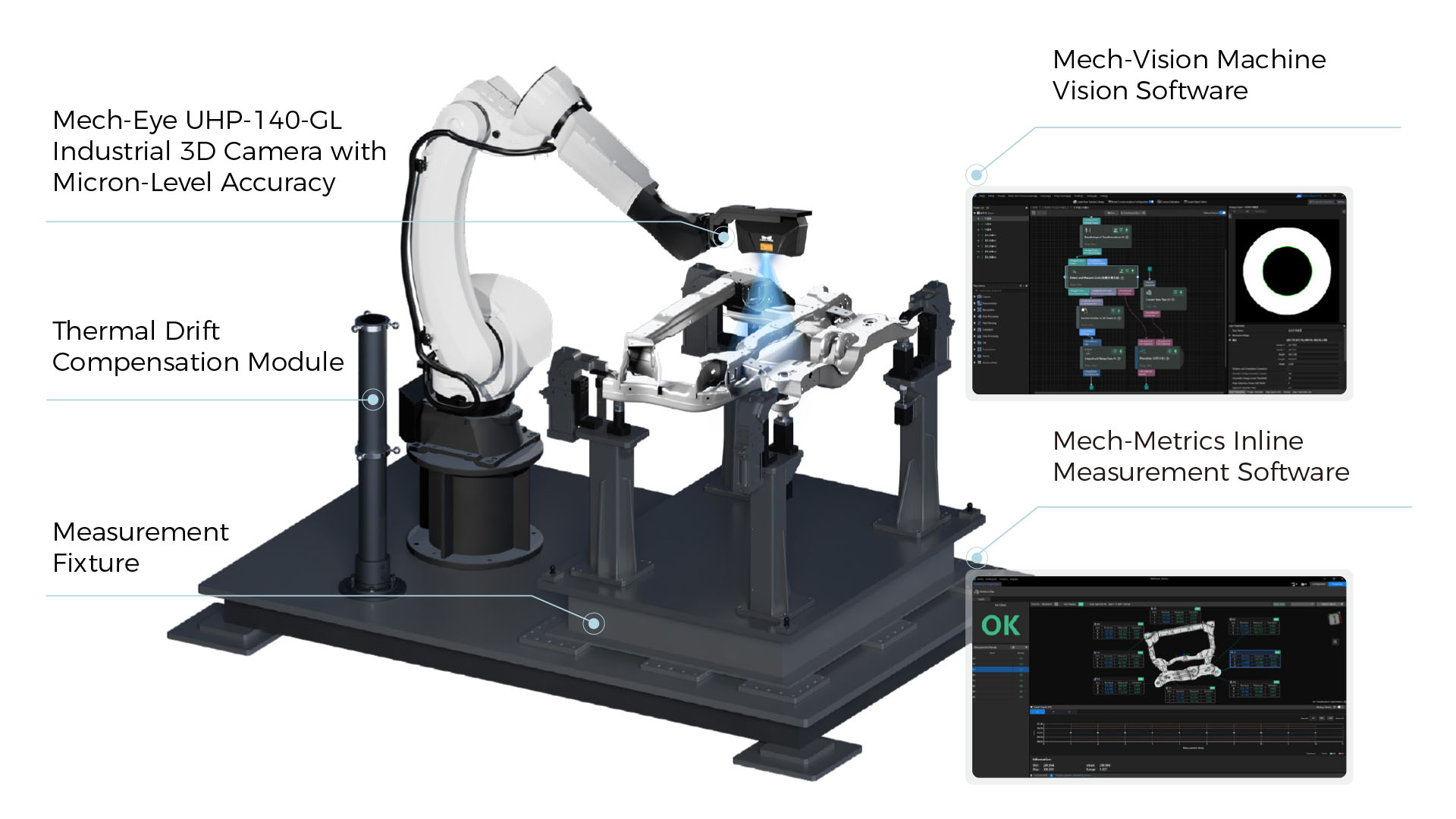

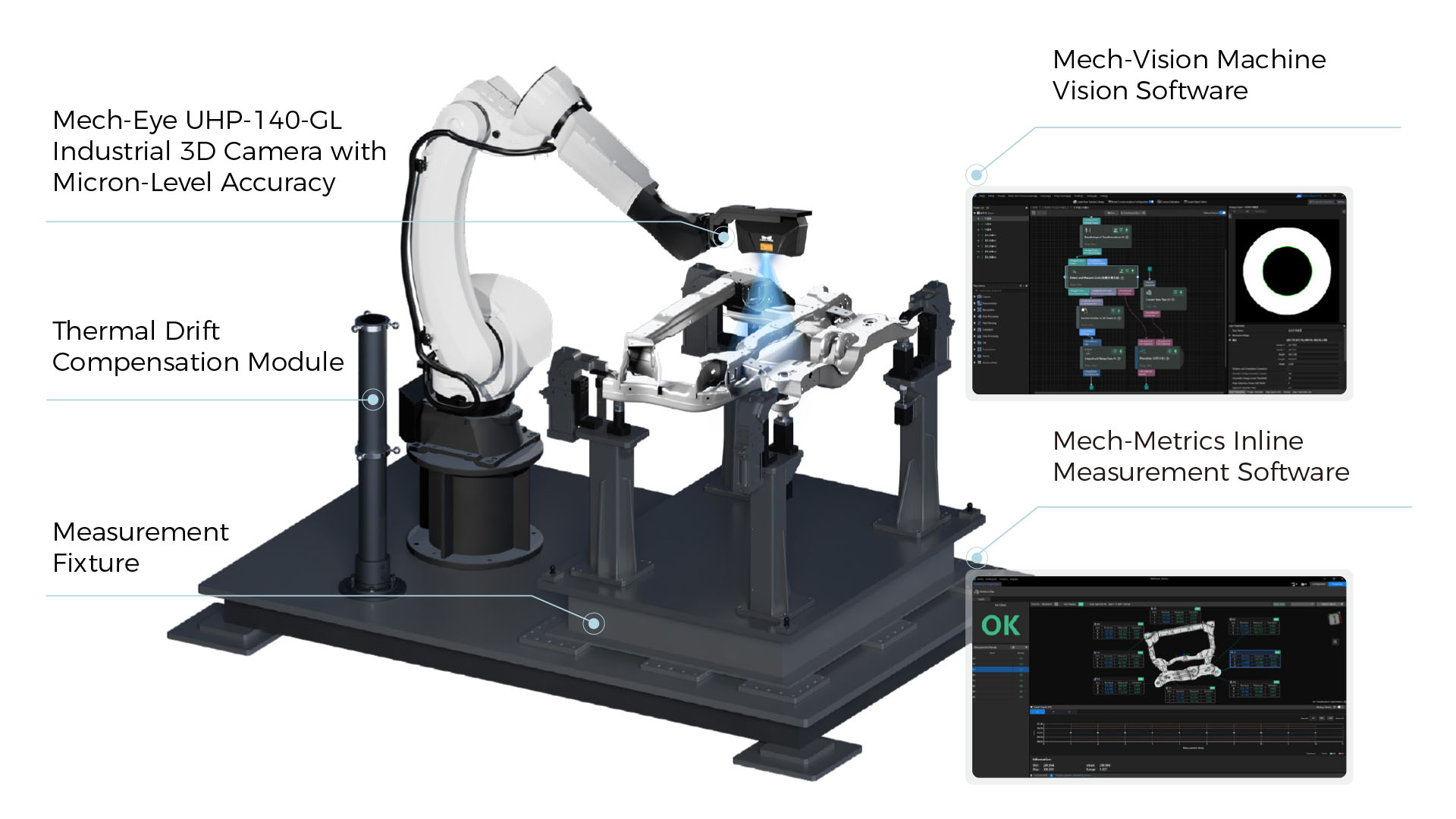

All-in-One Inline Measurement System

Mech-Eye UHP-140-GL Industrial 3D Camera

with Micron-Level Accuracy

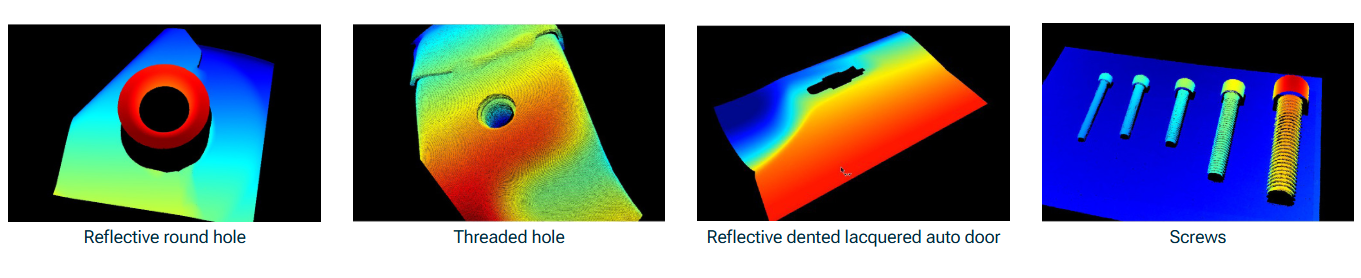

With advanced image-fusion and anti-reflection 3D reconstruction algorithms, the Mech-Eye UHP-140-GL reduces blind spots and generates high-quality point clouds of reflective and complex-shaped parts. It is ideal for inspection and measurement applications that require strict GD&T compliance.

|

|

|

|

Reflective round hole | Threaded hole | Reflective dented lacquered auto door | Screws |

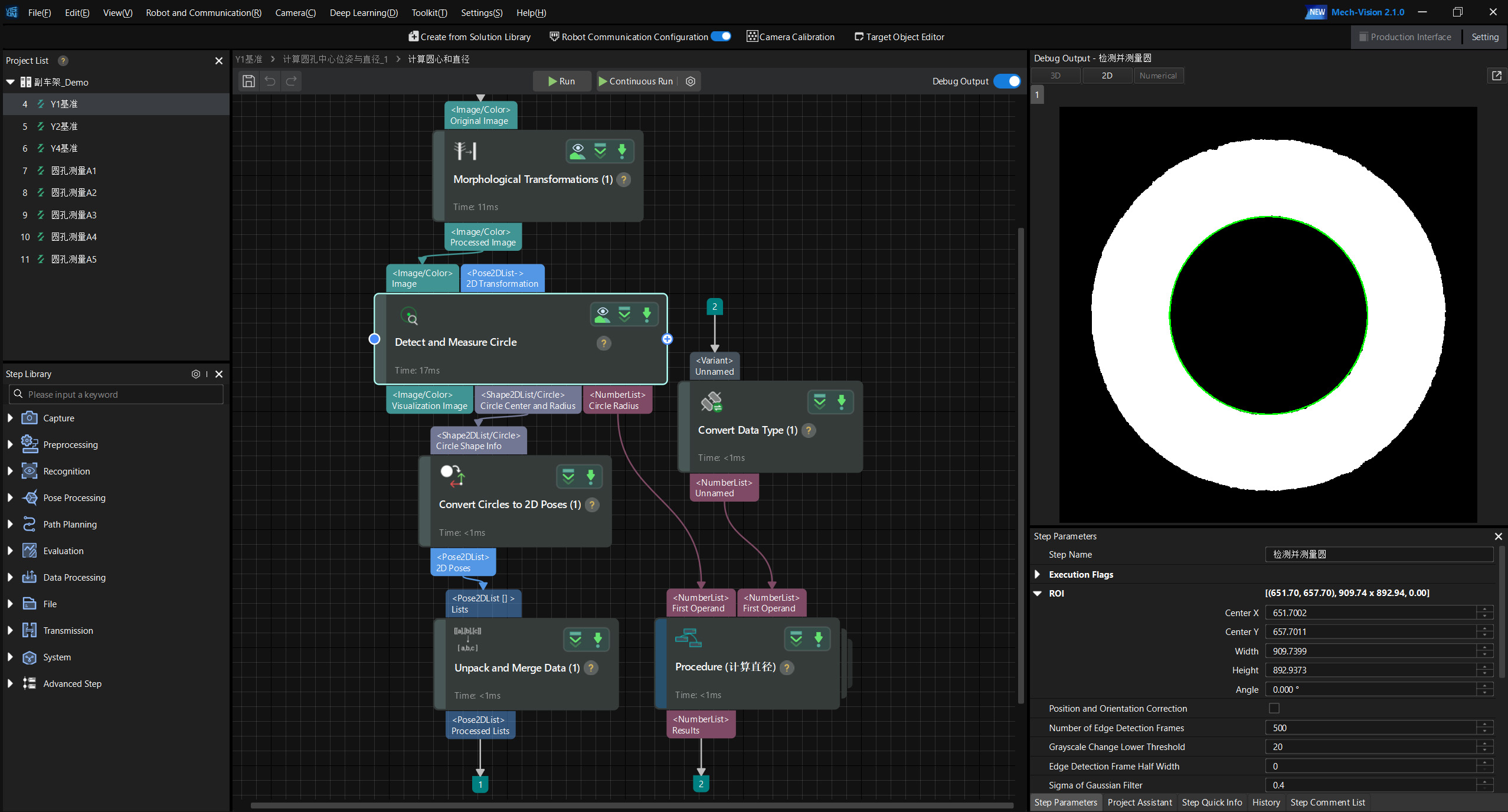

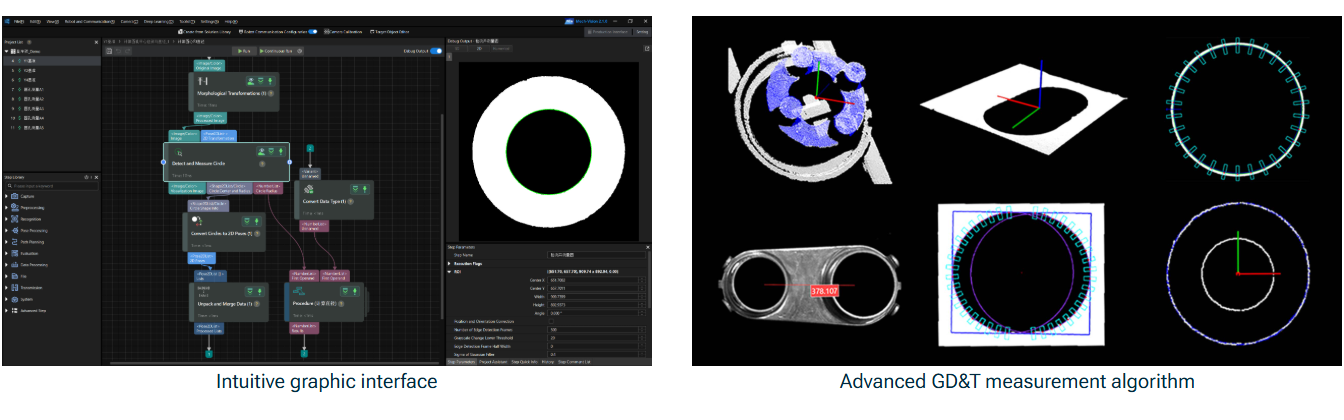

Mech-Vision Machine Vision Software

Leveraging point-cloud processing and GD&T measurement algorithms, Mech-Vision supports a wide range of inspection and measurement applications across the automotive, EV battery, and other demanding industries.

|

|

Intuitive graphic interface | Advanced GD&T measurement algorithm |

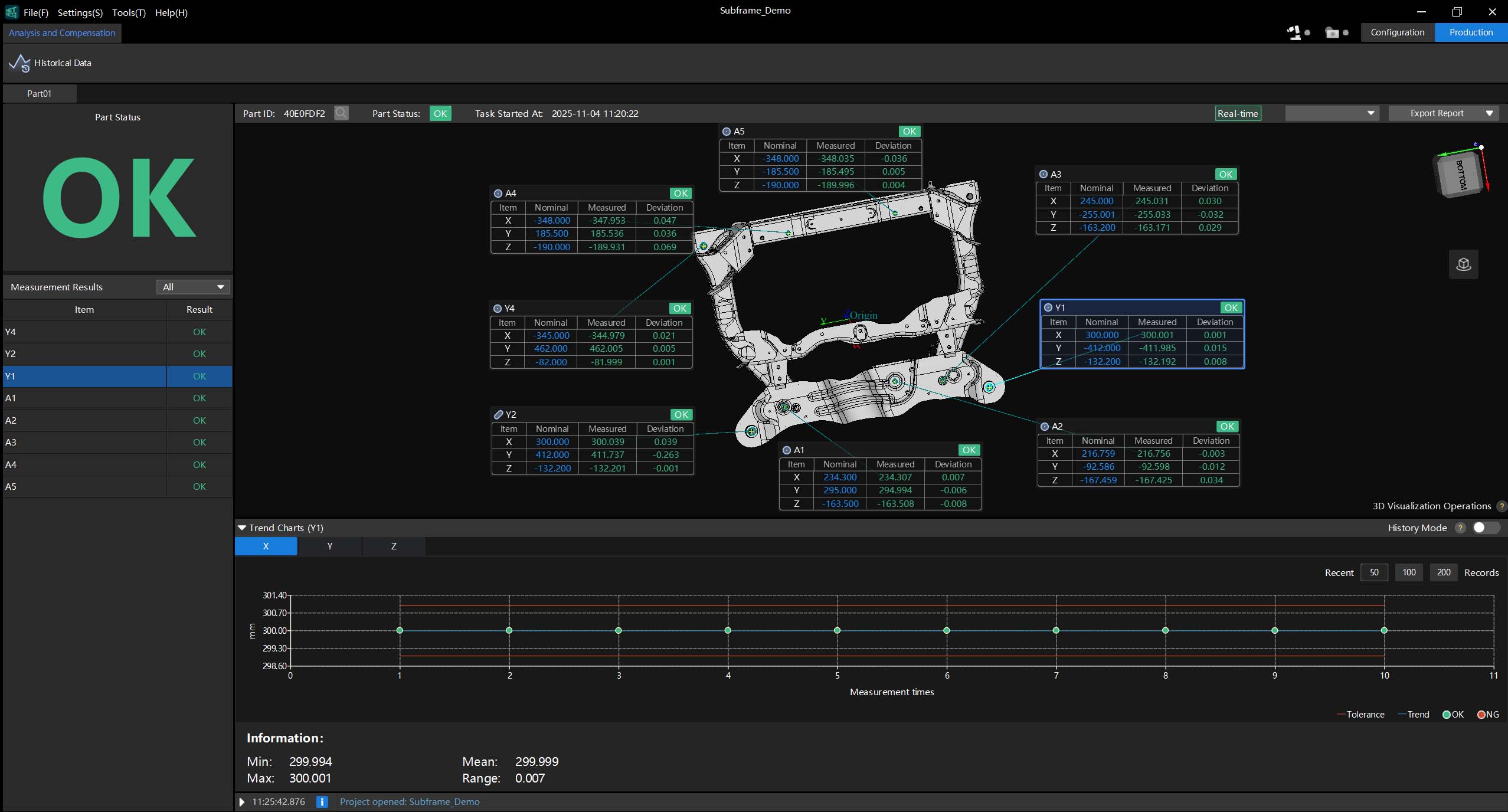

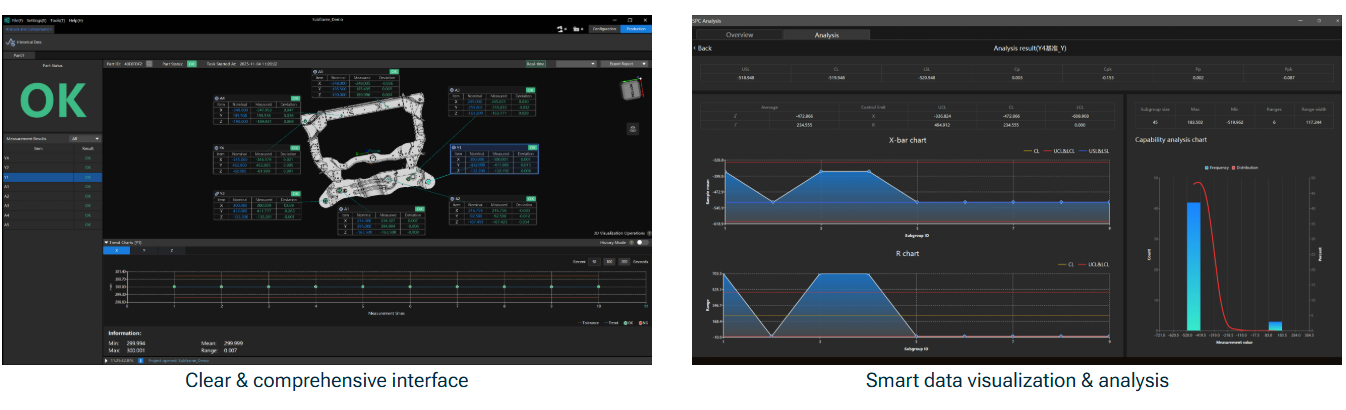

Mech-Metrics Inline Measurement Software

Self-developed software that manages key inline measurement processes—such as communication setup, measurement feature configuration, and workflow management—and visualizes production data with SPC quality-control analysis to reveal real-time process trends and product characteristics, significantly improving deployment efficiency.

|

|

Clear & comprehensive interface | Smart data visualization & analysis |

Why Choose Mech-Mind 3D Vision Inline Measurement System?

|

|

|

Industry-Leading Accuracy |

| High-Speed Measurement |

Micron-level 3D camera with advanced 3D measurement algorithms achieves CMM-comparable accuracy within ±0.2 mm. |

|

Optimized measurement logic and “capture-and-move” mode enable single-point measurement in as fast as 2 s, cutting cycle time by over 90% compared with standard CMM systems. |

|

|

|

100% Real-Time Inline Inspection |

| Full-Process Data Traceability |

Integrates seamlessly into high-speed production lines, inspecting all products in real time for precise quality control. |

| Real-time measurement data output with robust data management, supporting process improvement and quality control. |

|

|

|

| Thermal Drift Compensation |

| Rapid Deployment & Flexible Changeover |

Self-developed thermal drift compensation effectively eliminates downtime, ensuring long-term accuracy and system stability. |

| The highly integrated and standardized system enables quick deployment, while its flexible adaptability allows rapid part changeovers. |

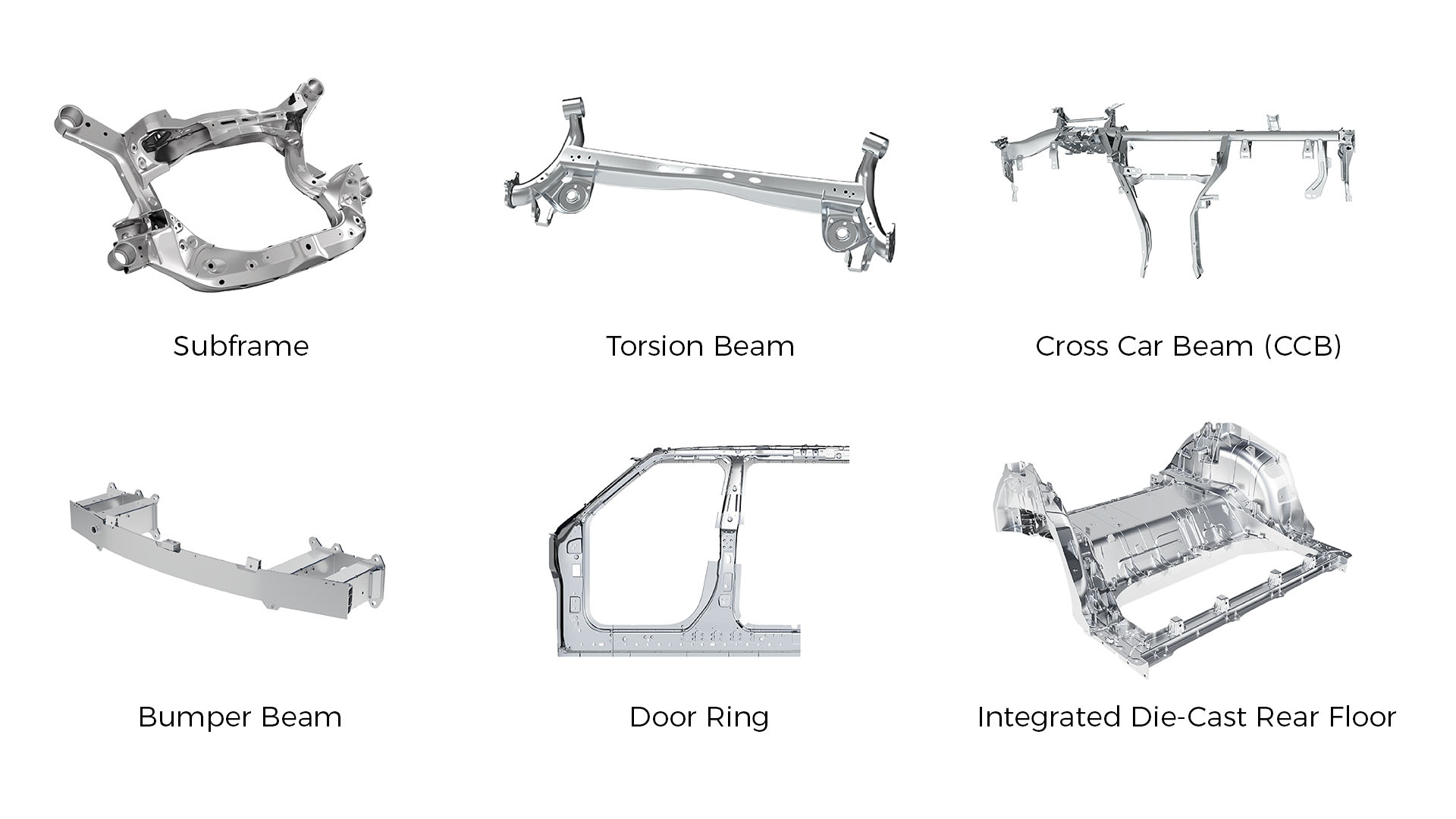

Typical Applications

Designed for core stages of automotive production — from component manufacturing to sub-assembly welding — the Mech-Mind Inline Measurement System delivers high-precision dimensional inspection of key features on automotive parts, sub-assemblies, and more.

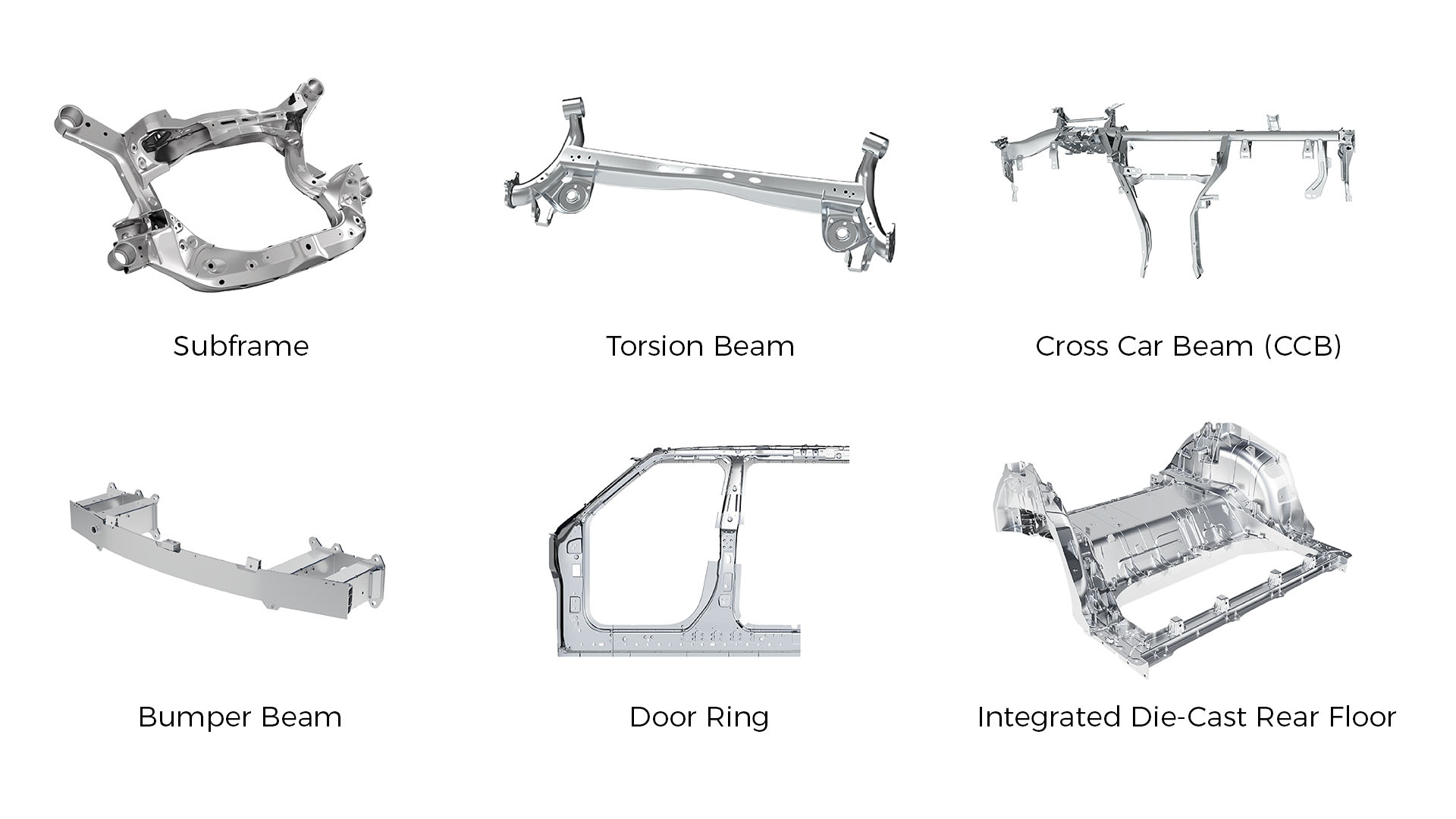

Typical Automotive Parts

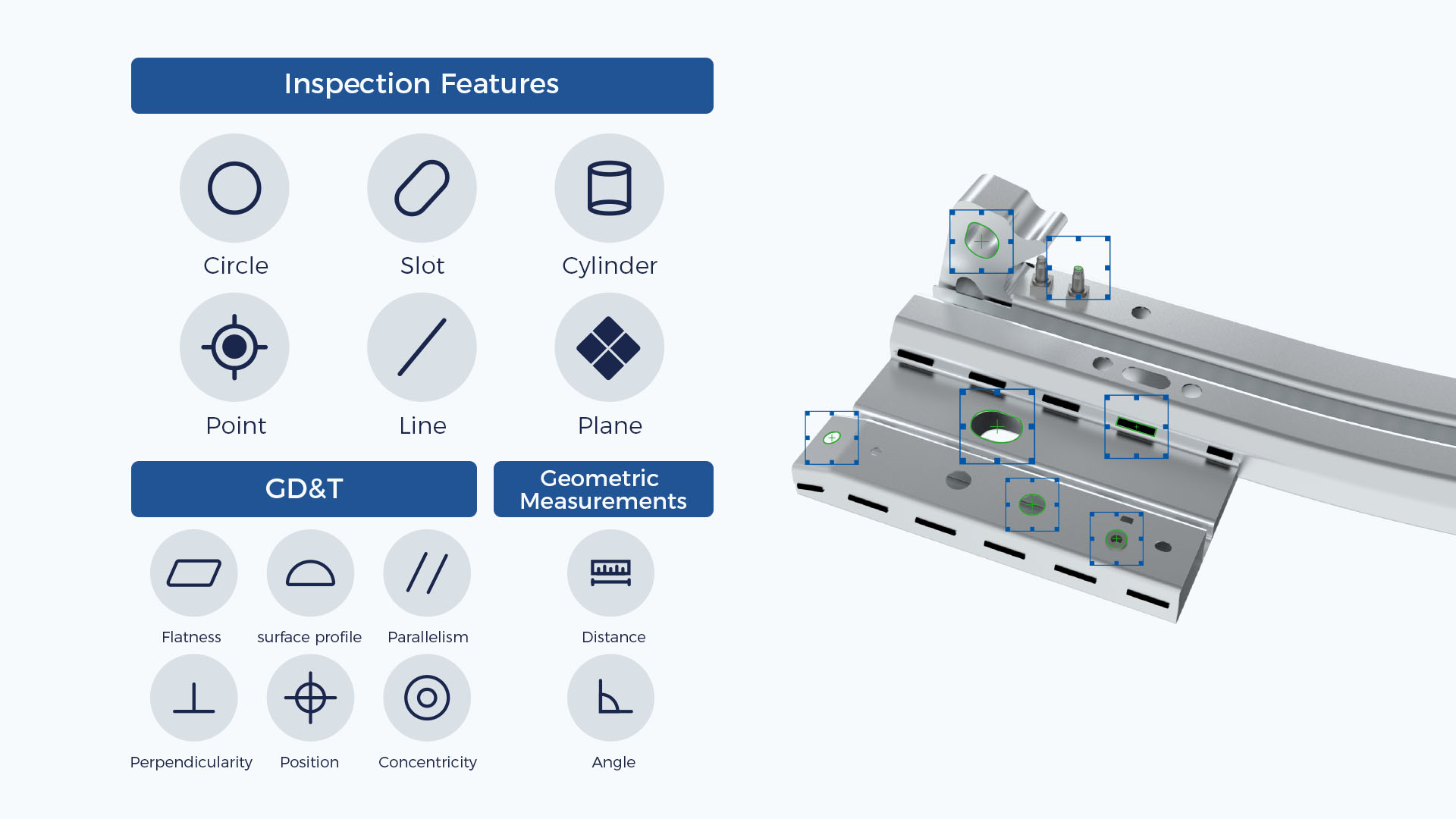

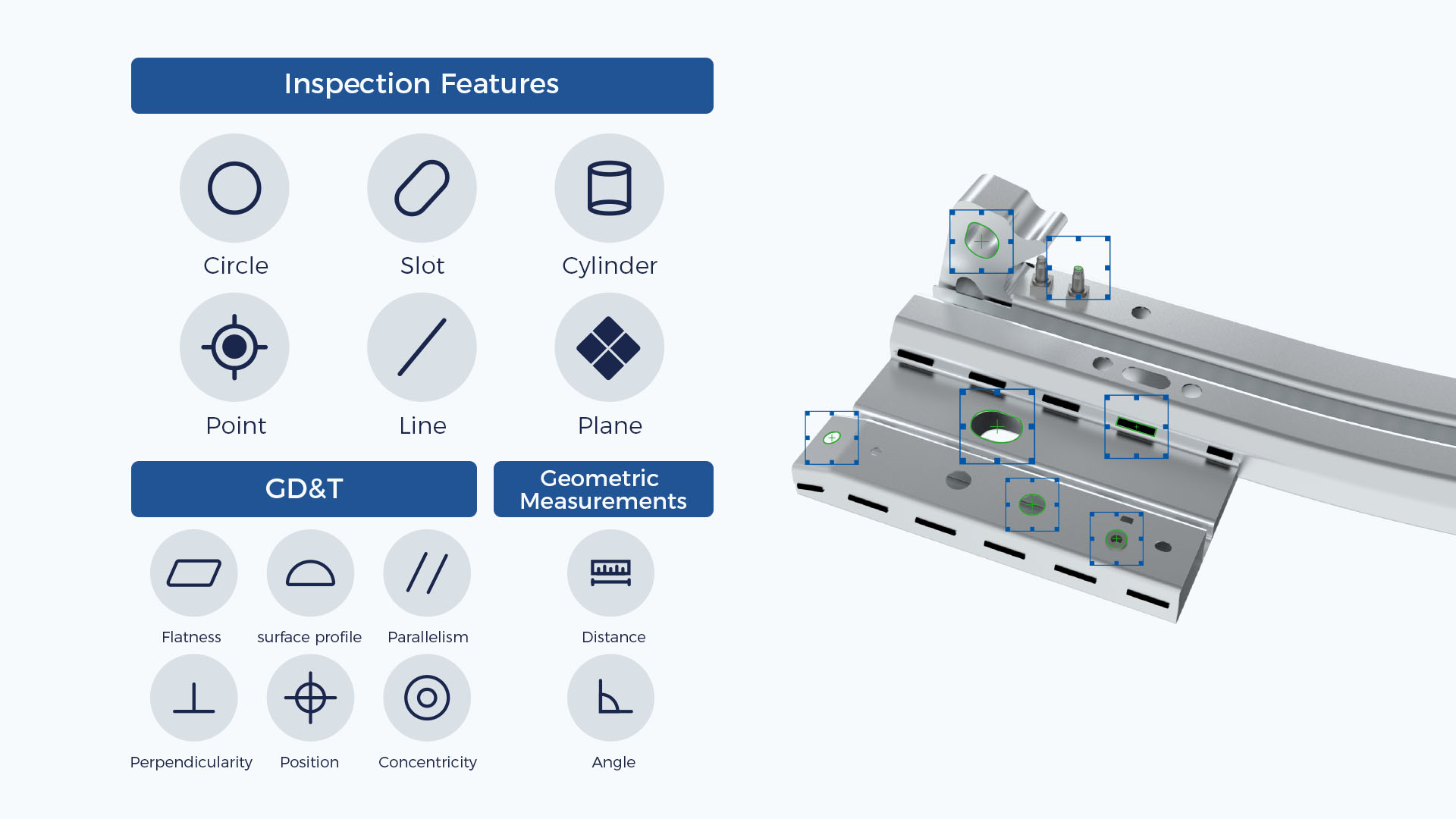

Typical Inspection Features

All-in-One Inline Measurement System

Mech-Eye UHP-140-GL Industrial 3D Camera

with Micron-Level Accuracy

With advanced image-fusion and anti-reflection 3D reconstruction algorithms, the Mech-Eye UHP-140-GL reduces blind spots and generates high-quality point clouds of reflective and complex-shaped parts. It is ideal for inspection and measurement applications that require strict GD&T compliance.

Mech-Vision Machine Vision Software

Leveraging point-cloud processing and GD&T measurement algorithms, Mech-Vision supports a wide range of inspection and measurement applications across the automotive, EV battery, and other demanding industries.

Mech-Metrics Inline Measurement Software

Self-developed software that manages key inline measurement processes—such as communication setup, measurement feature configuration, and workflow management—and visualizes production data with SPC quality-control analysis to reveal real-time process trends and product characteristics, significantly improving deployment efficiency.

Why Choose Mech-Mind 3D Vision Inline Measurement System?

|

|

|

Industry-Leading Accuracy |

| High-Speed Measurement |

Micron-level 3D camera with advanced 3D measurement algorithms achieves CMM-comparable accuracy within ±0.2 mm. |

|

Optimized measurement logic and “capture-and-move” mode enable single-point measurement in as fast as 2 s, cutting cycle time by over 90% compared with standard CMM systems. |

|

|

|

100% Real-Time Inline Inspection |

| Full-Process Data Traceability |

Integrates seamlessly into high-speed production lines, inspecting all products in real time for precise quality control. |

| Real-time measurement data output with robust data management, supporting process improvement and quality control. |

|

|

|

| Thermal Drift Compensation |

| Rapid Deployment & Flexible Changeover |

Self-developed thermal drift compensation effectively eliminates downtime, ensuring long-term accuracy and system stability. |

| The highly integrated and standardized system enables quick deployment, while its flexible adaptability allows rapid part changeovers. |

Typical Applications

Designed for core stages of automotive production — from component manufacturing to sub-assembly welding — the Mech-Mind Inline Measurement System delivers high-precision dimensional inspection of key features on automotive parts, sub-assemblies, and more.

Typical Automotive Parts

Typical Inspection Features