Modern automobiles are more complex and require more processes to produce, which increases the possibility of mistakes. However, automakers cannot afford this kind of error in a market where competition is fierce.

Manufacturers and their distributors depend highly on an extremely effective method to prevent defects and errors at various production steps to deliver the quality products consumers expect.

One of the most efficient ways to prevent significant errors is by using automation using 3D machine vision in automotive manufacturing robots. Machine vision is used in various applications in the automotive sector, primarily for robotic instruction, assessments, and more.

These devices are used in different ways in the automotive supply chain, ensuring quality products, speed, ease, and greater efficiency in the production process.

Why is Machine Vision Important in Automotive Manufacturing?

Machine vision has a huge role to play in the mechanized automotive sector. As this industry grows, so is the importance of machine vision. These devices play various roles depending on their involvement in the production process. Car manufacturing automation uses car manufacturing robots that can be applied in the automotive industry. It helps detect flawed connectors and other parts, which helps avoid disaster later on.

Combining the machine vision software, along with the capabilities of cameras, to comprehend data or bar codes allows for secure identification of a wide range of objects.

In the automotive automation industry, machine vision can come in either the 2 Dimension (2D) or the 3 Dimension vision (3D), and they do an image analysis in sequences. The assembly line can examine the location and orientation of different components. You can also use them to check the number of welds and identify faulty surfaces before painting.

Machine vision offers a lot of benefits, one being that it saves cost since they apply two technologies which makes them very efficient and offers safety in the workplace between people and machines. Here are the significant benefits of having machine vision in car manufacturing automation.

1. Machine vision provides flexibility in robotic systems

Automotive manufacturing robots that cannot see (blind robots) can only do the same task over and over, provided there are no disparities. Vision-guided robots consider disparities as they function. For instance, they can allow parts to be picked randomly, different part adjustments, and more.

2. It optimizes speed

Automotive manufacturing robots can optimize logistics, production, and quality assurance processes. They are applicable in every kind of industrial function for precise and rapid detection of different things leading to a gain in momentum and automation in production procedures.

Car assembly robots have algorithms that need only milliseconds to identify and process information in images. Vast commodities can easily be examined automatically, plus in fast successions.

3. Machine vision offers precision and accuracy

Automotive manufacturing robots provide high accuracy when it comes to operations involving inspections. Despite being efficient in inspection operations being beneficial when it comes to the vision of machines, how accurate and precise the robot is the most important thing when it comes to vision mechanization.

Each part used in a vehicle should function excellently and fit nicely into a vehicle. The accuracy of inspectors that perform manually is much less than an intelligent camera, plus any flaws can be harmful to the buyer and expensive to the producer.

Using 3D Vision for Assembly Robots

The demand for standard inspection and guarantee over various industrial sectors is growing by the year, and the 3D vision for car assembly robots is growing by the day because of this. It aids industries in producing quality products, which plays a big part in the pattern.

Mech-Mind offers 3D vision cameras and automation solutions for automotive robots that are efficient when examining even the tiniest details of the products. These machines are not affected by surrounding conditions or the product as they operate.

The three-dimension vision is applied in bin picking to classify, pick, place, and detect a part or product to get the desired result, a normal process in smart factories and warehouses. You can also use them in depalletizing and palletizing, which need difficult work and repeated maneuvers.

Automotive manufacturers in the automotive manufacturing industry are typically using automotive manufacturing robots for inspecting parts, and in the e-commerce sector and logistics to better monitor, track, move things, and more.

Real-time tracking of product quality

Manual inspections in the automotive industry can lead to inaccuracies, become physically demanding, and even unsafe. This is where the 3D vision comes into play. With 3D vision, you are assured of accuracy, ease, precise results, and more in automotive manufacturing automation.

3D vision allows real-time tracking of products according to the limitations in control, trends, and the specification of products. It can measure products precisely in real-time through inspections and providing feedback.

Using a robot-mounted sensor on the assembly line

The 3D vision uses a robot-mounted sensor, which fastens production speed and makes products have more excellent quality. These robots can be guided or programmed, plus you can choose to use both simultaneously to finish production tasks in assembly lines in automotive manufacturing.

Furthermore, you can use them for parts that are too tiny, complicated, or fragile for humans. They can also provide feedback on whether various parts fit perfectly together or not.

Scanning features

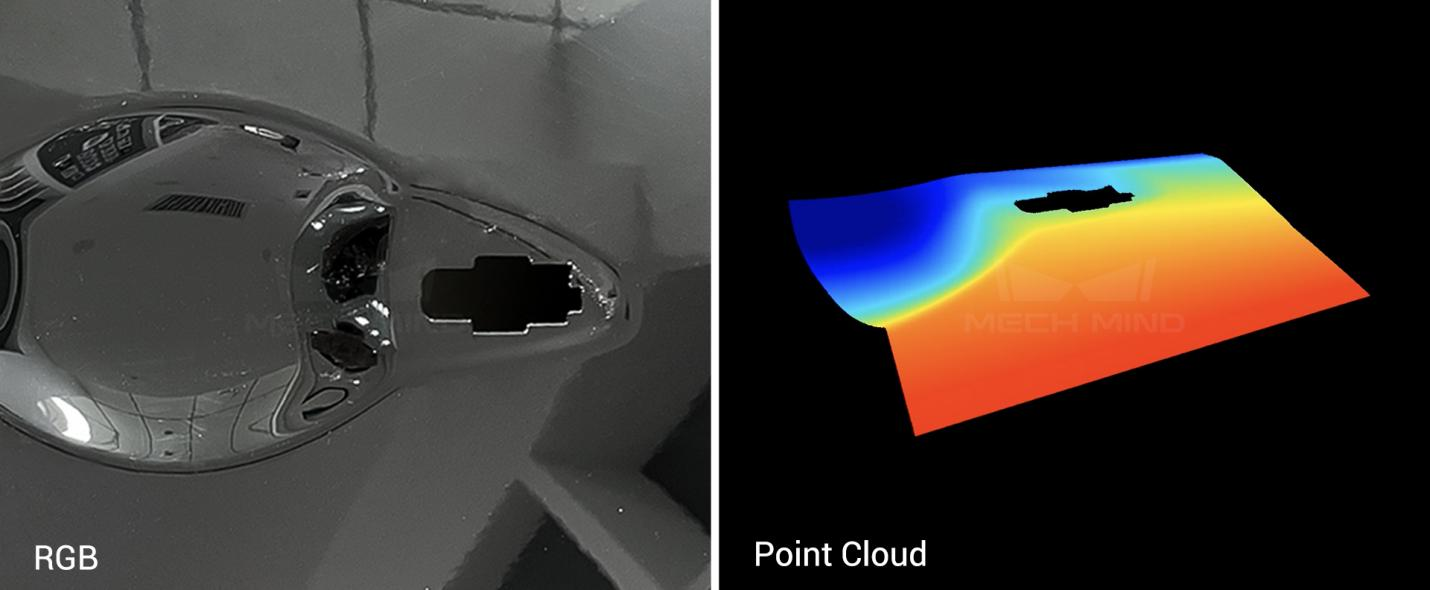

3D vision comes with a 3D camera that gives excellent precision or a large field of view, plus it can support different objects. The camera can also get hold of cloud information for car vehicles with complex and reflective components. For instance, the Mech-Eye UHP-140 with micron-level accuracy can output 3D point clouds of reflective and shiny parts with astounding accuracy and sharp details.

High brightness dented lacquered auto door; the handle position is easy to scatter light

Mech-Eye UHP-140 @ 0.3 m, point cloud rendered by height

The Mech-Mind Way

Machine vision is significant, has made automotive manufacturing more effortless, and has long-term benefits in production, making them a good investment plan. Robots in the automotive industry that apply 3D vision offer accuracy, precision and optimized speed in operations.

Mech-Mind is the leading provider of industrial 3D vision cameras, machine vision software, and intelligent robotic solutions. Centered on giving its consumers efficiency, and ease, 3D vision reduces physical and manual effort in automotive manufacturing, which makes it a valuable asset for the automation sector and beyond.

To know which Mech-Mind 3D vision solutions match your business needs, consult our experts at: info@mech-mind.net