What are industrial robot arms?

Robotic arms are not only widely used tools capable of lifting extremely heavy and hazardous materials but also performing seriously complex or mechanized tasks. Like other robots, a robotic arm is made of different parts in order to ensure proper functioning. Most, if not all, people are aware of the importance of robots, but only a few know about parts of a robotic arm that often goes unmentioned. These are the 8 basic components you need to know before using an industrial robot arm.

What are the 8 main components of industrial robotic arms?

1. Control system

In a nutshell, controllers act as robot arm brains. They are the main processors of the factory robot arm and can either allow users for manual operation or act automatically as a program. They are the control consoles that come in an array of styles depending on the type of processing power required. Some controllers are simple, small joysticks, while in large factories and companies, you can find huge, complex computer systems.

2. Robot arm

The robot arm is the main section of robotic arm components that consists of three parts: the wrist, elbow, and shoulder, also known as joints. In general, the shoulder is located at the base of the arm and is connected to the controller. It can spin or move forward and backward. The elbow is located in the middle allowing the upper parts to move independently from the parts below. Finally, the wrist is located at the very end of the factory robot arm and is attached to the end effector.

3. Sensor system

Unlike older models, which had no sensors, the more advanced ones have them. Those sensors are in charge of allowing robot hands to sense the environment around them and react and adapt accordingly. For example, these sensors are a must if you own two or more robots working in close proximity to prevent collisions. Or they allow the robot to find the perfect grip on a sensitive or fragile object to prevent damaging it.

4. Vision system

Strictly speaking, when we talk about what are the main components of robots, a robotic vision is an advanced technology that allows a robot to see. In other words, these advanced systems enable them to inspect, navigate, identify and then handle tasks or objects. A robotic vision system relies on one or more cameras connected to a computer. In short, the computer contains high advanced processing software programs to help the robot interpret what is around it. This is how do robots see things around them.

5. Drive system

Drivers are literally the motors in between joints in charge of controlling the robot's maneuvers and movement. They usually use belts similar to those we find in car engines.

6. End of arm tool

The end of arm tool is a device that acts as the hand of the robotic arm. In most cases is composed of two or three claws that can open or close on command. Even more, the wrist part can also spin, making maneuvering equipment, material, and other stuff easy.

7. Power systems

A robot can't go anywhere without juice. In humans, our bodies use a super complex process of decomposing food into fat for powering organs, muscles, and other systems. In robots, on the other hand, there are a number of different substances to give a factory robot arm itself get up and go! The most common are electricity (from solar power, batteries, and AC wall current), liquid, and air.

8. Graphical interface software (GUI)

As the technology is growing day by day, new models have graphical interface software to achieve the ability to control and command the robotic arm. As it is a time-saving and efficient controlling method, those robots with graphical interface software are better for picking and placing the material.

Improve your robot arms' setup with Mech-Mind Tech

Mech-Eye

Combining robotic arms with Mech-Eye Industrial 3D Camera helps robotic arms not only to understand their surroundings but also to interact with them. Mech-Eye Industrial 3D Camera can generate complete, accurate, and highly detailed point clouds with natural and clearly aligned colors for different kinds of objects, including wood, cardboard, metal, ceramic, and plastic.

Mech-Vision

Mech-Vision Graphical Machine Vision Software can make operating your robot arm way easier through an easy-to-use graphical interface and make robot tasks like depalletizing, precise order picking, area locating, and so on precise, accurate, and fast.

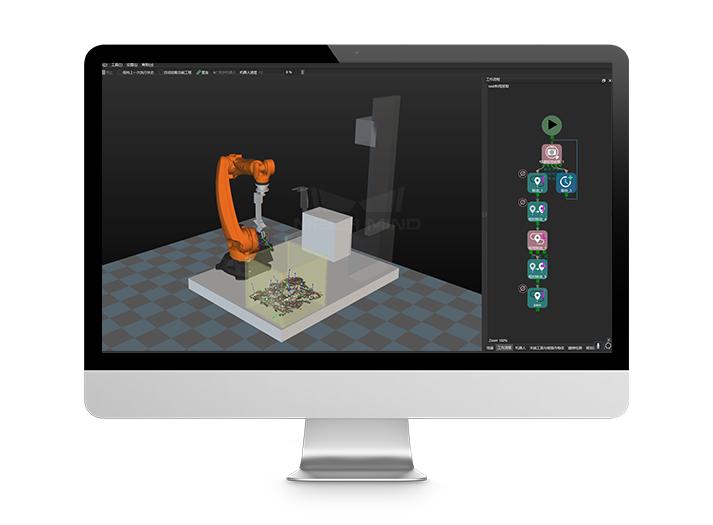

Mech-Viz

With Mech-Viz Robot Programming Software, you can get the entire 3D motion sequence in just one click. This is the latest generation of an all-in-one visualized programming environment for robots.

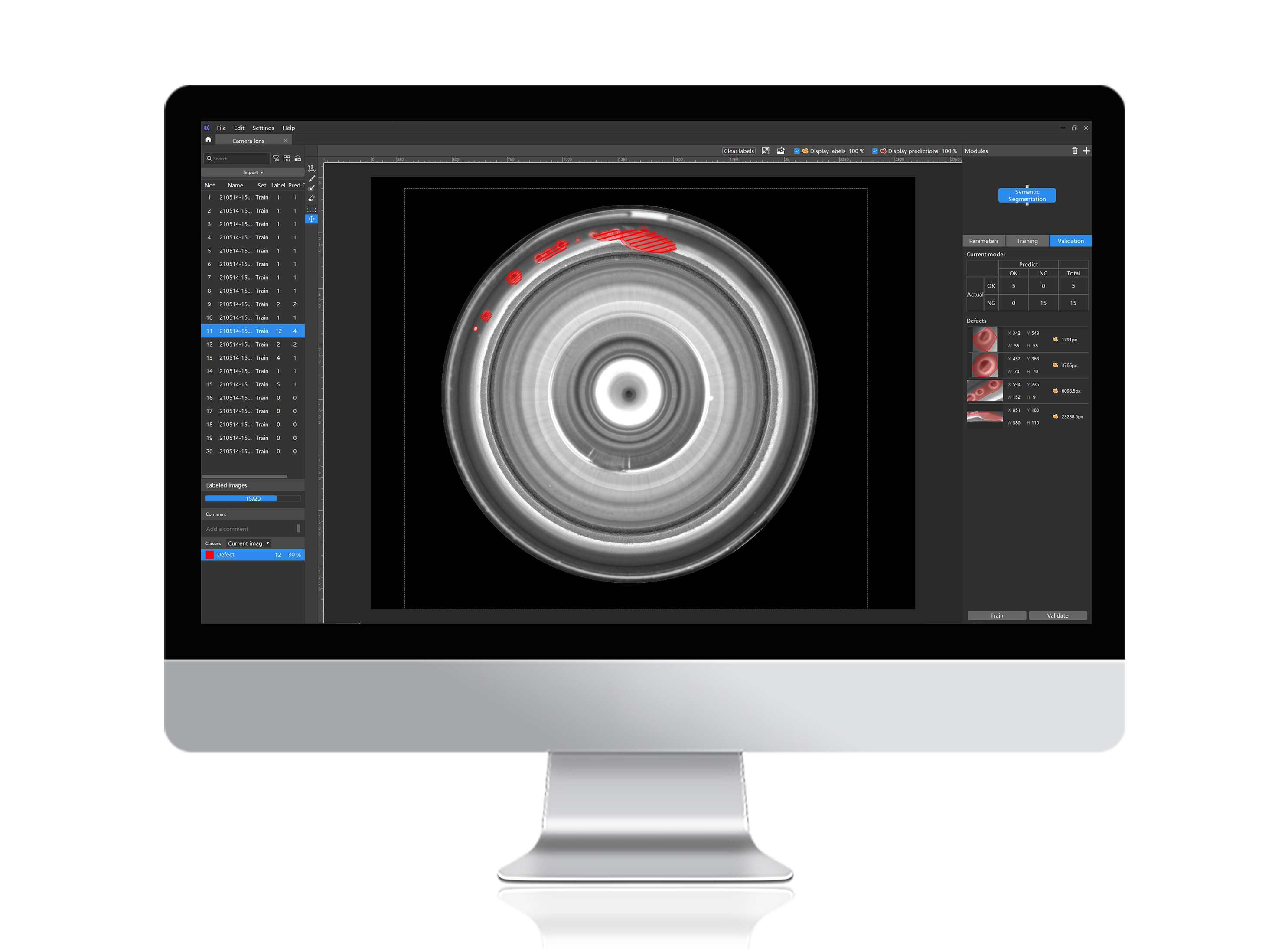

Mech-DLK Deep Learning Software comes with built-in multiple compelling deep learning algorithms and a super easy-to-use graphical interface you can utilize to efficiently solve a number of different complex quality inspection issues, reducing labor costs and improving product quality and efficiency.

The Wrap Up

While using robots helps with general productivity and efficiency, there are many additional benefits that your company can have by incorporating the Mech-Mind products. The best part? No line of code is necessary to program your unique tasks - everything is done through the easy-to-use graphical interface. If you need any further help regarding the topic, please do not hesitate to contact Mech-Mind consultants and get the most out of your business.