Typical robotic industrial applications are: transporting parts, locating parts, assembling, and quality control. Machine vision plays an integral role in these industrial applications as the eyes of the robot. Did you know that the global 3D machine vision market reached more than USD 1.5 billion in the previous year and is, according to statistics, expected to grow up to USD 3 billion between 2022 and 2027?

If you do the math, that is, compare this industry with others, the 3D machine vision market is one of the fastest-growing industries, and it's going to stay there for a while!

What are the major applications of industrial 3D vision?

1. Quality assurance and inspection

There has been a huge demand for quality assurance and inspection across different industrial verticals in the last several years, which is actually pushing the 3D machine vision market growth. Automated vision inspection systems help manufacturing companies ensure a fast production cycle and product quality. This is where the Mech-Mind 3D camera comes into play if you want to measure even those teeny-tiny details of target objects without the influence of other conditions from working environments or target materials.

2. Positioning and guidance

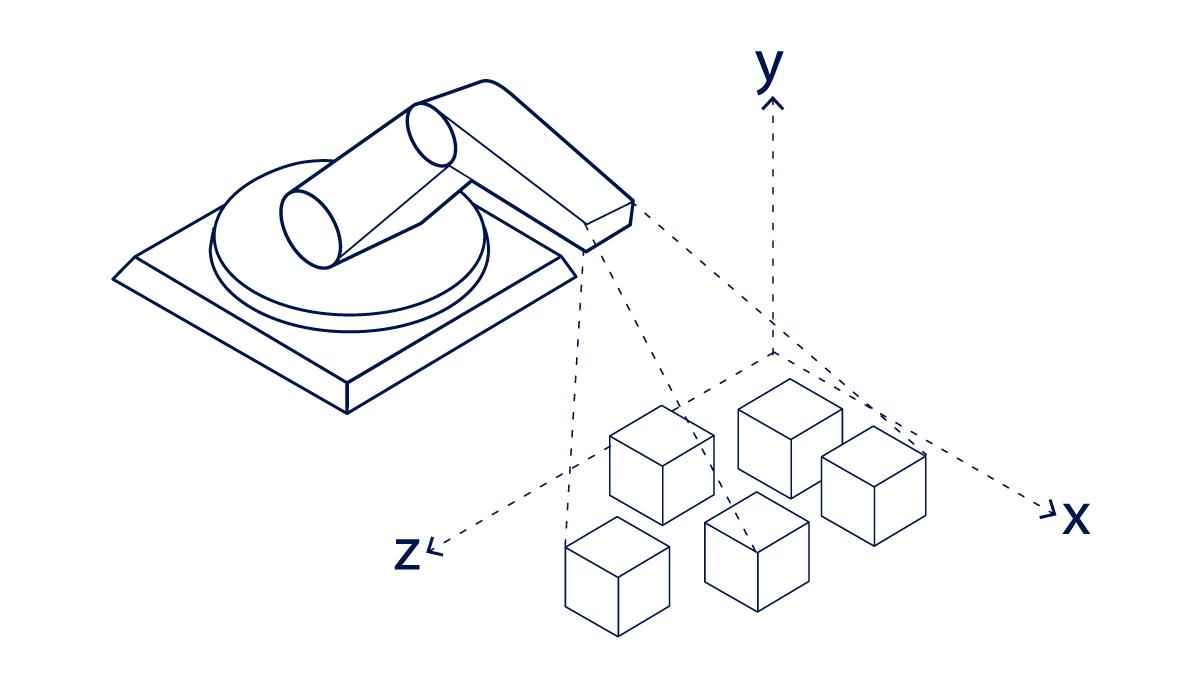

Although robot systems have been around for decades, they have mostly been working blind. Nowadays, thanks to industrial machine vision, robotic systems can do both things: locate the position of the part and its orientation to ensure the correct angle in order to perform proper assembling. Positioning and guidance can also be used to align with other machine vision tools. This is a very powerful feature of image and vision computing because different parts can be presented to the camera in different, unknown orientations during manufacturing.

3. Measurement

There's no doubt that 3D vision is the most reliable method for the precise three-dimensional measurements of complex 3D objects. Unlike traditional machine vision, which would struggle with measurements, new automated vision systems give precise details regarding the size and position of the object regardless of its color and height. It uses image sensors to record data in width, depth, length, and height while locating the position.

4. Identification

Automated vision systems play a vital role in part and product identification by reading barcodes, data codes, or even locating unique patterns on stuff based on size, shape, or color. This way, you can have more space to gather data, including manufacturer information, product identification, and so on and so forth.

5. Sorting

One of the greatest advantages of 3D vision is that it allows robots to quickly and accurately sort out defective pieces, scan bar codes, pick workpieces, sort, and other stuff for hours, which can be widely utilized in logistics, e-commerce, and manufacturing industries. 3D vision can also help robots perform loading and unloading. In short, it's the best thing you can get for fast-moving bulk materials that need to be classified, sorted, or even ejected.

What industries are 3D vision systems applicable to?

Palletization or depalletization is another area that can greatly benefit from 3D machine vision since those tasks require repeated maneuvers and are arduous work - companies can get the most out of their productivity through automated machines that complete those tasks with high speed.

Bin picking also relies on robotics and 3D machine vision to detect, classify, pick, and place an object to achieve the requested result. In fact, it is one of the most common processes in smart warehouses and factories.

Mech-Mind vision products are used in a wide range of industries, including:

Automotive manufacturers rely on 3D machine vision to inspect and test their parts with accuracy and efficiency, optimizing their operations at a whole new level.

The food industry is another area where automation is widely deployed for food processing, segmentation, and packing.

The logistics and e-commerce sector demands automation. It helps owners to run their business 24/7 and improves tracking, moving items, monitoring, and other operations.

The printing industry also utilizes 3D vision systems to detect anomalies in their prints like errors or inconsistencies in pattern, text, or color and helps with printing, labeling, and packing.

The Wrap Up

Choosing the right 3D vision system is of the utmost importance if you want to run your business full steam ahead, and that's why Mech-Mind is offering one-of-a-kind all-in-one AI+3D intelligent robot solutions. For any questions, please contact us!