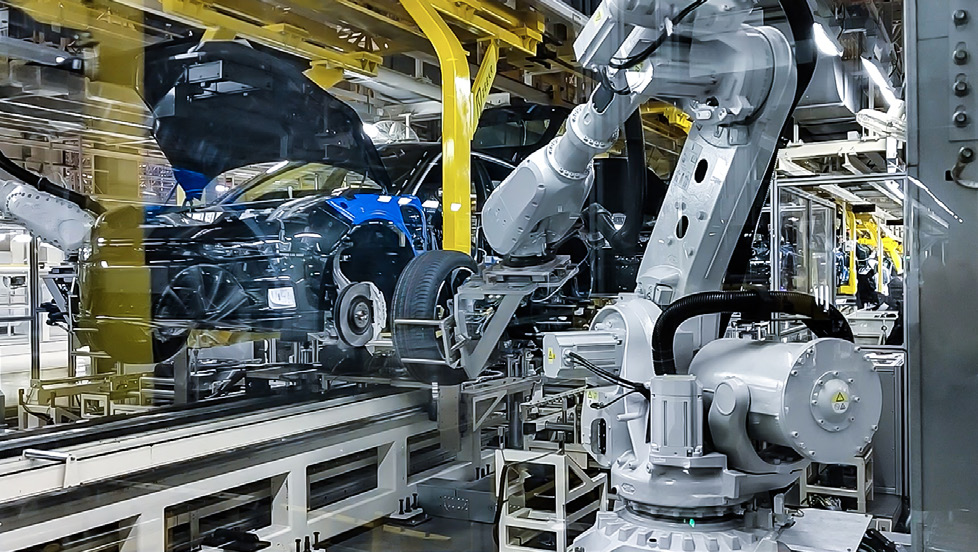

Intelligent pick and place robots have been becoming increasingly popular in factories because they significantly help streamline the work process by improving efficiency, productivity, and capability. In this article, we will be discussing what an intelligent pick and place robot is, how it works, and what it's usually used for.

What Is An Intelligent Pick and Place Robot?

An intelligent pick and place robot is a smart device with more maximized capabilities than the traditional robot. A pick and place robot merely refers to a mechanism capable of doing simple tasks like picking and placing parts within an assembly line. They're most inclined to handle repetitive and monotonous tasks while handling both tiny and big pieces — also pertained to the pick and place system. On the other hand, the intelligent pick and place robot can recognize and handle a variety of randomly piled items like parts, parcels, cartons, sacks, and more. They put these items at their appropriate positions, thereby guaranteeing relatively higher speed and consistency than usual.

Why Intelligent Pick and Place Robots Are Popular in Factories Nowadays?

Equipped with multiple intelligent algorithms like path planning and 3D vision, intelligent pick, and place robots make for well-suited, effective tools to deal with different complex situations in warehouses and factories.

For instance, intelligent pick and place robots can identify and grab a variety of objects that are piled in deep bins or those with either complicated structures or dark, reflective exteriors. It also guarantees precision and accuracy due to the built-in path planning algorithm, which allows these robots to avoid crashes and collisions.

Over a thousand cases have proved how intelligent pick and place robots are the best options for manufacturers because they further leverage work productivity. With this, Mech-Mind Robotics constantly prioritizes manufacturers' ideal pursuits and is adept at giving you high-quality, cost-effective pick and place robots alongside other tangible robotic solutions that can help businesses boost their overall productivity and efficiency.

What Are Intelligent Pick and Place Robots Used for?

Generally, the distinct mechanism of pick and place robots that most factories particularly find significant in work production is its robotic vision inspection, allowing it to recognize various parts to which it has been assigned, such as size, shape, location, color, orientation, and more. This enables the robot to accurately pick up the right place to be placed in its ideal location. With intelligent pick and place robots, it's the same — only better. Intelligent pick and place robots are empowered with various functions and features than the traditional but are especially suitable for dealing with repetitive or monotonous tasks.

Here are some of them.

Depalletizing: Intelligent pick and place robots also have the capability to identify cartons with different texts, cable ties, patterns, and tapes. Furthermore, they can also go on for days or months on end without shutting down nor without the requirement of human supervision.

Bin Picking: Since intelligent pick and place robots are smart devices, they're more than well-suited for bin picking since they can easily find different parts often mixed in deep bins. After this, they put these items at their designated places.

Assembly: When it comes to assembly lines, intelligent pick and place robots can conveniently identify and then quickly select the incoming pieces in the form of random shapes and sizes from a conveyor belt and then insert them accurately afterward. Furthermore, they can also finish the assembly all while the production is up and running.

Conclusion

The existence of intelligent pick and place robots paved the way for businesses to further improve their consistency, flexibility, accuracy, and speed of the work process. Moreover, these robots allowed many factories to leverage productivity without compromising cost-effectiveness or performance.

Now, the intelligent pick and place robot has evidently revolutionized production across the globe with an unstoppable trend of industry 4.0. Keeping this in mind, Mech-Mind Robotics adheres to the goal of pursuing the ubiquity of intelligent robots, allowing businesses more viable, affordable, and intelligent robotic options worldwide to help foster productivity all the more.