Quality control stands as the bedrock of success in manufacturing. However, achieving impeccable quality comes with its own set of challenges. Fortunately, advancements in 3D laser profilers have revolutionized quality inspection processes.

Yet, selecting the ideal 3D laser profiler can be daunting, even for seasoned experts. With countless products claiming the highest speed, accuracy, and resolution, how can you determine the right fit for your project? This blog provides valuable tips to guide you through the selection process:

1. Clarify your production objectives and project needs

Begin by identifying your production goals, whether it’s to streamline production cycles or to ensure top-notch product quality. Then, dive into details such as system configuration and sensor specifications, including field of view, scan rates, and resolution. Choose a profiler that best meets your project requirements, taking into account performance, ease of use, and cost-effectiveness.

2. Evaluate product specifications and engage with vendors

You might already have found that the specifications may vary slightly from one product to another on the market. This makes it difficult to compare them merely based on the datasheets.

To overcome this problem, it's best to directly communicate with your vendor. Their role is crucial in providing clarity on how they calculate the specifications and what sets their product apart. This can provide you with more useful technical details, insights, and potential challenges you might not be aware of, making you feel supported in your decision-making process.

3. Choose a trustworthy partner that can help you throughout your project lifecycle

A reliable partner goes beyond offering products; they provide support throughout your product lifecycle – assisting with sensor setup, offering comprehensive technical support, and providing timely post-purchase assistance. Look for these key qualities in a trusted partner:

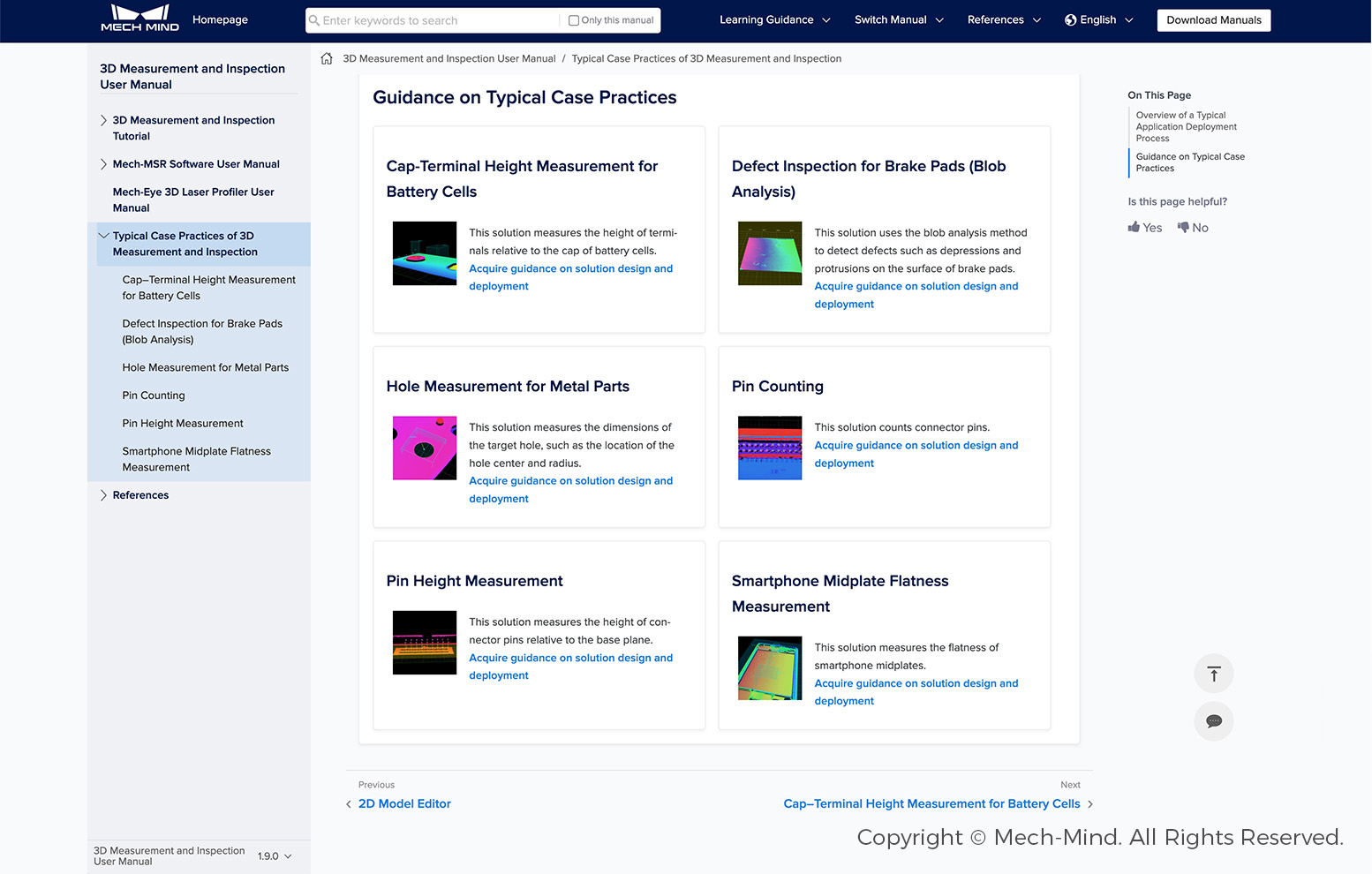

• Provide comprehensive documentation and video tutorials for your sensor setup, configuration, and common issues.

• Offer professional training and timely technical support from seasoned experts, whether on-site or remotely.

• Provide direct access to in-depth project insights.

• Possess extensive project expertise in solution design, development, and delivery.

The Mech-Mind way

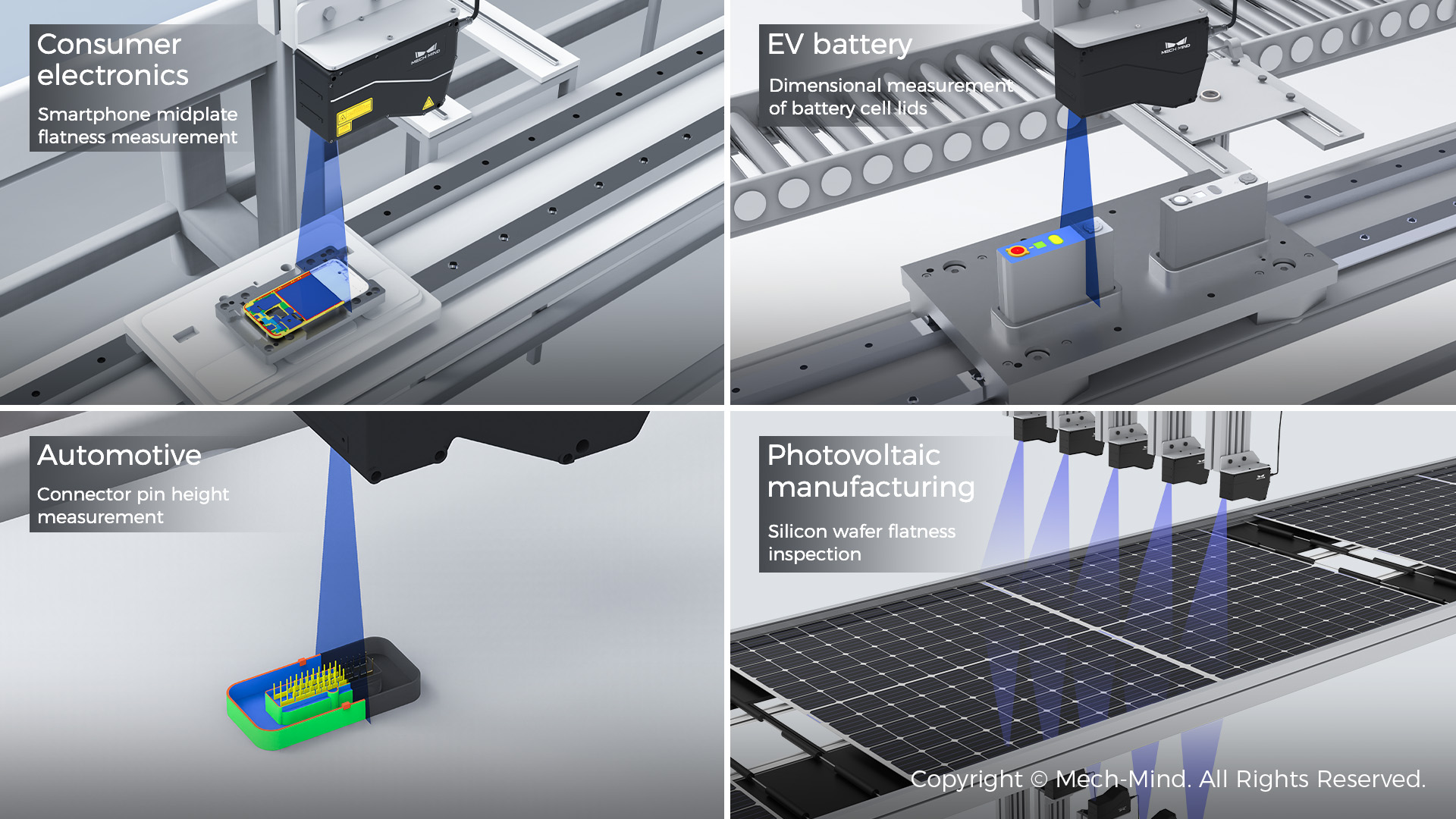

In today's dynamic manufacturing landscape, staying ahead of the competition requires more than just meeting quality standards – it demands continuous innovation and optimization of quality control processes. Mech-Mind offers top-of-the-line 3D laser profilers – the Mech-Eye LNX series – and AI-powered inspection software – Mech-MSR – to tackle diverse inspection tasks across industries.

Mech-Eye LNX 3D laser profilers come in two series: the Mech-Eye LNX-8000 series and the Mech-Eye LNX-7500 series. The LNX-8000 series boasts an impressive 4,096 profile points and a blazing-fast scanning speed of up to 15kHz, while the LNX-7500 series offers 3,200 profile points and a scanning speed of up to 10kHz. This level of detail and speed enables manufacturers to capture intricate surface features with high precision, even in high-speed production environments.

Complementing these advanced profilers is the Mech-MSR 3D measurement and inspection software. Compatible with both the LNX-7500 and LNX-8000 series, Mech-MSR facilitates end-to-end deployment of measurement projects, streamlining the inspection process from data acquisition to analysis. With Mech-MSR, manufacturers can leverage the full potential of Mech-Eye LNX profilers to conduct a wide range of inspections, including height measurement, object counting, flatness detection, defect localization, and more.

With Mech-Eye LNX 3D laser profilers and Mech-MSR software, manufacturers can elevate their quality control efforts to new heights, driving efficiency, reliability, and, ultimately, customer satisfaction.

Conclusion:

In conclusion, quality control is paramount in manufacturing, and Mech-Eye LNX 3D laser profilers, coupled with Mech-MSR software, offer solutions to industry challenges. With their unmatched precision, speed, and versatility, these innovative tools empower manufacturers to achieve excellence in every aspect of quality inspection.