Piece picking Inefficiencies in warehouses has caused many logistics and e-commerce companies to change from the use of typical robots to intelligent robotic solutions. With the development of 3D vision cameras and machine software for piece picking robots, robots can recognize and pick items of varying shapes and sizes more accurately and efficiently.

Equipping robots with the latest AI+3D Tech translates to collision-free movement, adjustable piece picking speed, intelligent path planning, and zero piece picking errors in warehouses. And with Mech-Mind 3D vision camera designed to precisely scan SKU’s of different sizes and shapes, piece picking inefficiencies are no longer a challenge.

As more advanced e-commerce and logistics WMS take center stage, the modern piece picking robots equipped with AI+3D, have by larger extended increased productivity.

What Effects Piece Picking Efficiencies?

Piece picking can be a tedious activity when performed for long hours. E-commerce growth over the past few years has forced many companies to work 24/7 to meet customer orders. Such working environments have caused a huge demand for intelligent robots with the eyes and brains to solve the challenges affecting piece picking efficiencies.

Challenge 1: Products or items are manufactured in different sizes, shapes, and weights. While normal robots are designed to handle a defined task, modern warehouses are filled will different SKUs packaged in varied materials.

Challenge 2: Difficulties in integrating robots with the right hardware and software systems cause piece picking efficiencies.

Challenge 3: Some warehouses continue to have rigid workflow designs. This makes it difficult to incorporate new warehouse piece picking technologies.

Challenge 4: Manual barcode scanning has not only been causing piece picking inefficiencies but also product misplacements in warehouses.

Challenge 5: The slow piece picking processes from donor totes to order totes causes delays in the order fulfillment process, ultimately affecting the entire warehouse procedures.

How AI + 3D Guided Robots Improves Piece Picking Efficiencies

Whether it's piece picking rate or warehouse rigid workflow systems, combining AI algorithms with 3D machine vision cameras in robots eliminates piece picking challenges. For robots in your warehouse to seamlessly suit the designed workflow designs, software with intelligent path planning for robots is essential. Here is how AI+3D vision technology will improve robot piece picking efficiencies:

Solution 1: AI + 3D guided robots scan and recognize items/objects accurately and correctly

When using a piece-picking robot equipped with a 3D vision camera, the camera scans items in the inventory bin. If integrated with a powerful AI algorithm, items are quickly recognized, picked and placed in the right order tote. With the AI+3D vision technology on your robots, piece picking errors are solved.

In warehouses where thousands of different SKUs have to be handled every day, AI + 3D vision-guided robots are of immense help. With this technology, it's possible to instruct robots to sort, pick and place items in order bins thus solving piece picking challenges.

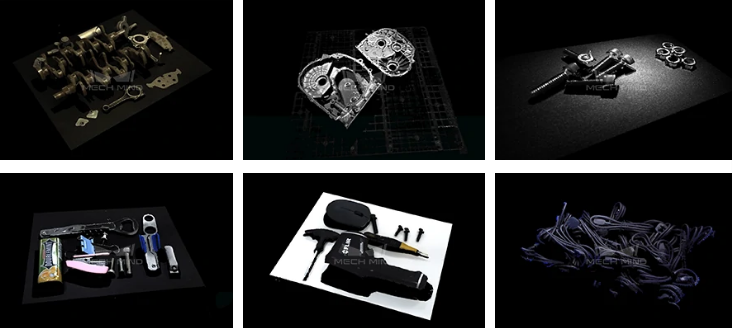

Our Mech-Eye industrial 3D cameras have the capability to quickly recognize items/objects of whatever size, shape and structure.

Solution 2: AI + 3D vision technology improves scanning speed during piece picking process

The traditional object scanning methods are slow, error-prone and monotonous. But with AI and 3D vision cameras in robots product scanning is faster and more accurate.

As supermarkets, logistics and warehouses continue to diversify products and orders increase, scanning challenges are better solved by using AI + 3D vision-guided robots. No matter how reflective the product surfaces are 3D vision cameras combined with Mech-Vision Machine Vision Software will scan the items faster and accurately.

Solution 3: AI + 3D technology enables robots to grab and pick items of varied shapes and sizes

In whichever industry you are, it’s now easy and safe to grab and pick objects of any size, shape and angle courtesy of AI+3D machine vision cameras. And no matter the complexity of products, the AI algorithm enables piece picking robots to grab the item at any angle. With Mech-Eye Industrial 3D Camera mounted on your robot, expect precise scanning and picking of different shaped products – night time or day time.

Solution 4: AI + 3D guided robots makes piece picking process easy to monitor

AI algorithms simplify the piece picking process by making it easy to monitor item recognition results. The intelligent algorithm also enables the seamless integration of robots with WMS systems. With the AI+3D and WMS systems working simultaneously, inventory management is simple.

Where To Get AI + 3D Robotics

Mech-Mind is among the most trusted companies for AI + 3D vision robotic solutions. Equipping piece picking robots with a 3D vision camera and Mech vision software from Mech-Mind eliminates piece picking challenges.

In online retail supermarkets where sorting individual items is marred with inaccuracies and time wastage, Mech-Mind AI + 3D robotic solutions are used to help scan and sort items accurately and with high speed.

Conclusion

Piece picking in warehouses has been characterized by inefficiencies. Slow piece picking rate, product tracking challenges, sorting issues and inability to integrate WMS systems with the piece picking process are no longer a challenge to logistical, industrial or warehouse companies. AI + 3D vision solutions have solved most of the above mention piece picking inefficiencies.