There has been a belief that industry 4.0 has failed to significantly impact production due to problems in implementation. In the past decade, that attitude has changed considerably due to technological advancements. Emerging robotics technologies are at the forefront of spurring smarter manufacturing.

Artificial intelligence technologies have been used collaboratively with industrial robots to expand the spectrum of automation of manufacturing. The most advanced artificial intelligence technologies that drive smart manufacturing include 3D machine vision and machine learning.

Types of Latest Industrial Robotics Technologies

3D Machine Vision

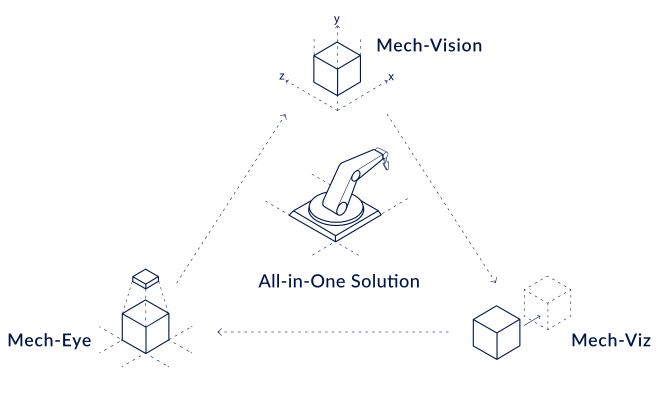

Machine vision technologies are indispensable for smarter manufacturing. 3D machine vision technologies have been incorporated in robotics to enhance self-learning, optimization, and control of robots. The advantages organizations realize from autonomous robots in industrial settings include the accurate completion of complex tasks with minimum intervention. Machine vision systems are fitted with communication networks that enable the intelligent exchange of information between devices and machines through sensors, enhancing optimization of the production line for demand changes. Industrial cameras have image processing systems that automate data collection and analysis, which is faster than manual data handling. The systems are more accurate with data analysis which reduces error in decisions. Mech-Mind provides 3D machine vision and deep learning software, which are essential for automating robots, contributing immensely to smart manufacturing.

Machine Learning

Machine learning involves AI algorithms that improve automatically by using data and experience to produce useful analytical models. This technology is important for the programming of robots to accurately execute their applications.Machine learning enables robots to optimize their movements to fit their work environment. The ability is achieved through training on data on the shape of objects and the appropriate way of handling them.

For example, vision-guided robots for order picking are trained using machine learning techniques. Such robots can pick a wide variety of objects such as sacks, cartons, or packets by adjusting to accurately handle them and avoid damages in the process.

Path Planning

Path planning is another application of machine learning to design the movement of robots in the industrial environment to avoid collisions. The process is essential for smart manufacturing environments because collisions may damage inventory and slow-down production. Intelligent planning algorithms help industrial robots minimize and eradicate instances of collision and crash.

Overall, machine vision and deep learning, among other technologies, will continue to enhance robotics and enable smart manufacturing through real-time data collection, analysis, and optimization of movements.

Advantages of Smart Manufacturing

Artificial intelligence technologies and AI have been critical in developing autonomous robots. Robots can be used for surveillance using 3D machine visions technologies in various environments. The emerging uses of robots promise increased awareness in the management of industrial processes and proactive risk management. Robotics can also be used in riskier industrial environments with extreme radiation or poisonous inventory. Robotics links organizations to the benefits of smart manufacturing. The advantages associated with smart manufacturings include efficiency, improved productivity, and high-quality products, which are essential in globalized markets.

Improved Efficiency

Smart manufacturing ensures various parts of the production line are efficient, resulting in cost reduction through reduction of idle time, real-time reporting, improved traceability, and quicker throughput.

Increased Productivity

Automation of complex tasks ensures more time is spent in actual production resulting in improved productivity. Integration of robotics ensures continuous production for extended periods and eliminates bottlenecks in the production processes. The ability to produce more increases an organization’s revenue and profitability, which is the goal of every business organization.

Higher Quality Products

Markets increasingly demand high-quality products, and smart manufacturing technologies are progressively matching that need. Robotics, 3D machine vision, AI technologies, and other technologies improve accuracy in the execution of production activities, ensuring that the final products are of superior quality.

Organizations cannot ignore smart manufacturing because it will drive differentiation which determines competitiveness and brand identity. As organizations continue to globalize, the need for automation, remote surveillance, and intelligent execution of industrial processes will be indispensable. Hence, confidently say that automation is the future of manufacturing.

Summary

Robotics contributes immensely to the development of smarter manufacturing, mainly through automation. Robots are increasingly used for a wide range of activities from simple picking and placing to more complex tasks such as designing and the execution of industrial processes either through control systems or autonomously. Robotic technologies such as the machine learning and 3D machine vision continue to drive automation which is essential for smart manufacturing.