Mech-Mind AI + 3D Vision Solution

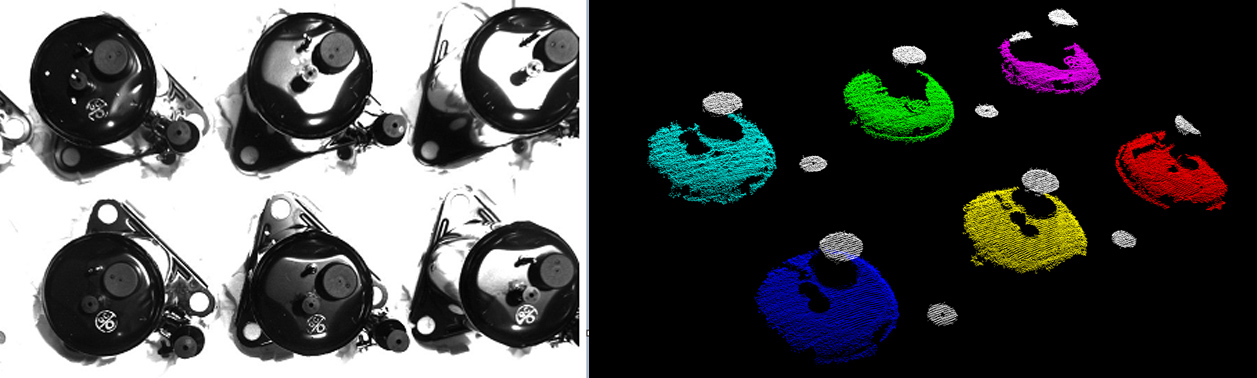

1. Mech-Eye PRO M-GL industrial 3D camera is highly accurate and with anti-reflection. For black parts with considerably reflective surfaces, high-quality 3D data can be generated. The accuracy of picking and placement is better than 1 m, meeting the precision of the assembly. Mech-Eye Industrial 3D camera with high protection level can adapt to the harsh environment such as dust and vibration.

2. With the layout of fixing Mech-Eye PRO M-GL industrial 3D camera on the mechanical arm (Eye in Hand), the field of view is more flexible, and the bottom plate adaptation problem can be solved while saving costs for clients.

3. Built-in advanced vision algorithms such as deep learning, with which robots can recognize black compressors of various sizes and considerably reflective surfaces and pick them one by one, with high recognition and picking rate as required by clients.

4. With customized matching collection tools, robots can recognize hundreds of new compressor models in a short period of time.

5. Intelligent routing algorithm optimizes robot motion speed while avoiding collisions and providing stability. It supports assembly during production line movement.

6. Robot programming software Mech-Viz supports almost all major-brand robots.