Mech-Mind General-Purpose "Eye + Brain" for Robots

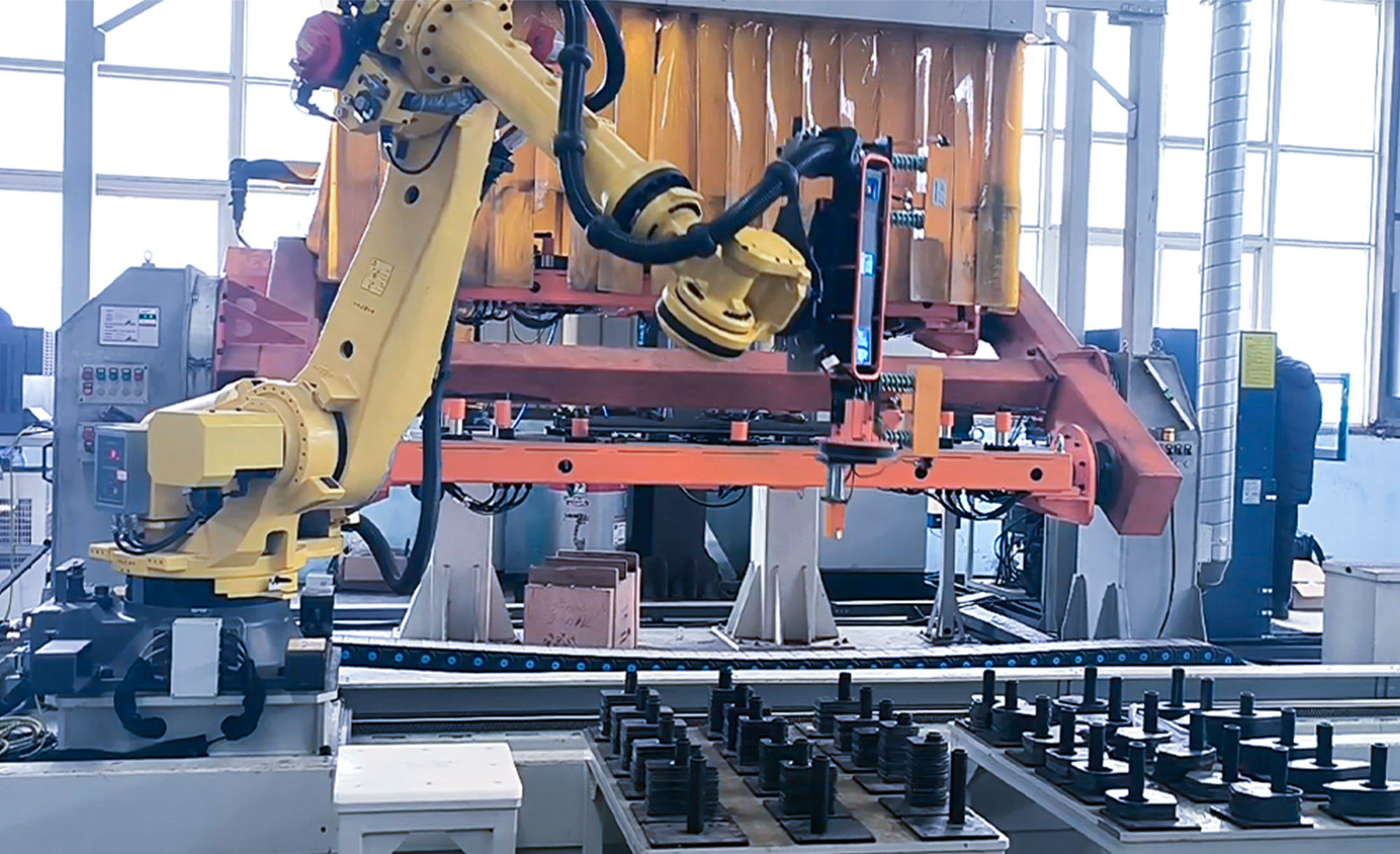

Project Site

Workflow:

Mech-Mind's "Eye + Brain" solution (including high-precision 3D cameras and AI software suites) enables robots to autonomously detect mixed rectangular tubes and plates, verify part pose, plan collision-free pick paths, and perform high-accuracy pick-and-place into welding fixtures. The customer integrates the system into their welding stations, enabling paired picking and welding with stable motion control.

Advantages:

1. Mech-Eye LSR L-GL high-precision 3D camera generates high-quality point clouds of overlapping rectangular tubes and plates from distances over 2 m.

2. Achieves accurate recognition despite strong ambient lighting and welding arc interference.

3. Effectively handles parts with dark surfaces and extremely similar geometric structures.

4. Accommodates large positional deviations of incoming parts (up to ±50 mm) while still enabling safe, accurate part locating and picking.

5. Integrated AI path planning and collision-detection algorithms guide robots to collision-free, optimized motions.

6. Precise motion control ensures reliable pick-and-place into welding fixtures, enabling consistent paired spot welding.

7. Designed for harsh factory environments—operates reliably under high temperatures, welding spatter, and dust.

Results:

· Significantly increased production line automation, intelligence, and flexibility.

· Improved machine tending accuracy and welding consistency.

· Reduced manual handling of hazardous operations, decreasing operator exposure and improving workplace safety.

· Stabilized cycle times and improved overall throughput.

· Enabled reliable, repeatable paired welding across multiple part types.

Click here to watch the real-world case video.