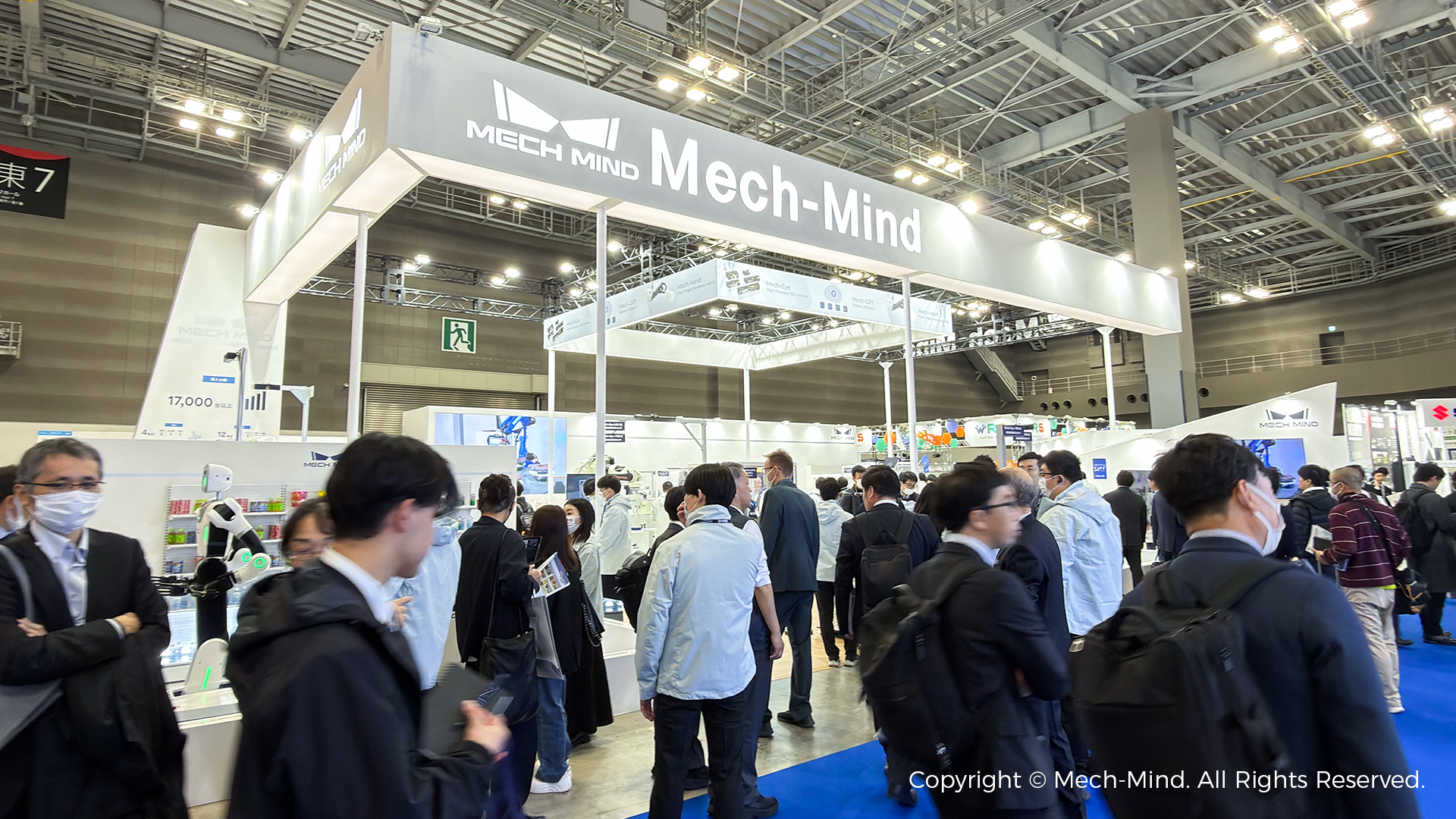

Mech-Mind's booth at iREX 2025

From December 3 to 6, the International Robot Exhibition (iREX 2025) was held at Tokyo Big Sight under the theme "Sustainable Societies Through Robotics." The expo emphasized human–robot coexistence and collaboration, and explored how cutting-edge robotics technologies can be applied across many areas of life. Nearly 700 leading companies from around the world gathered on-site to showcase the latest advances in humanoid robots, embodied intelligence, and other frontier robotics technologies.

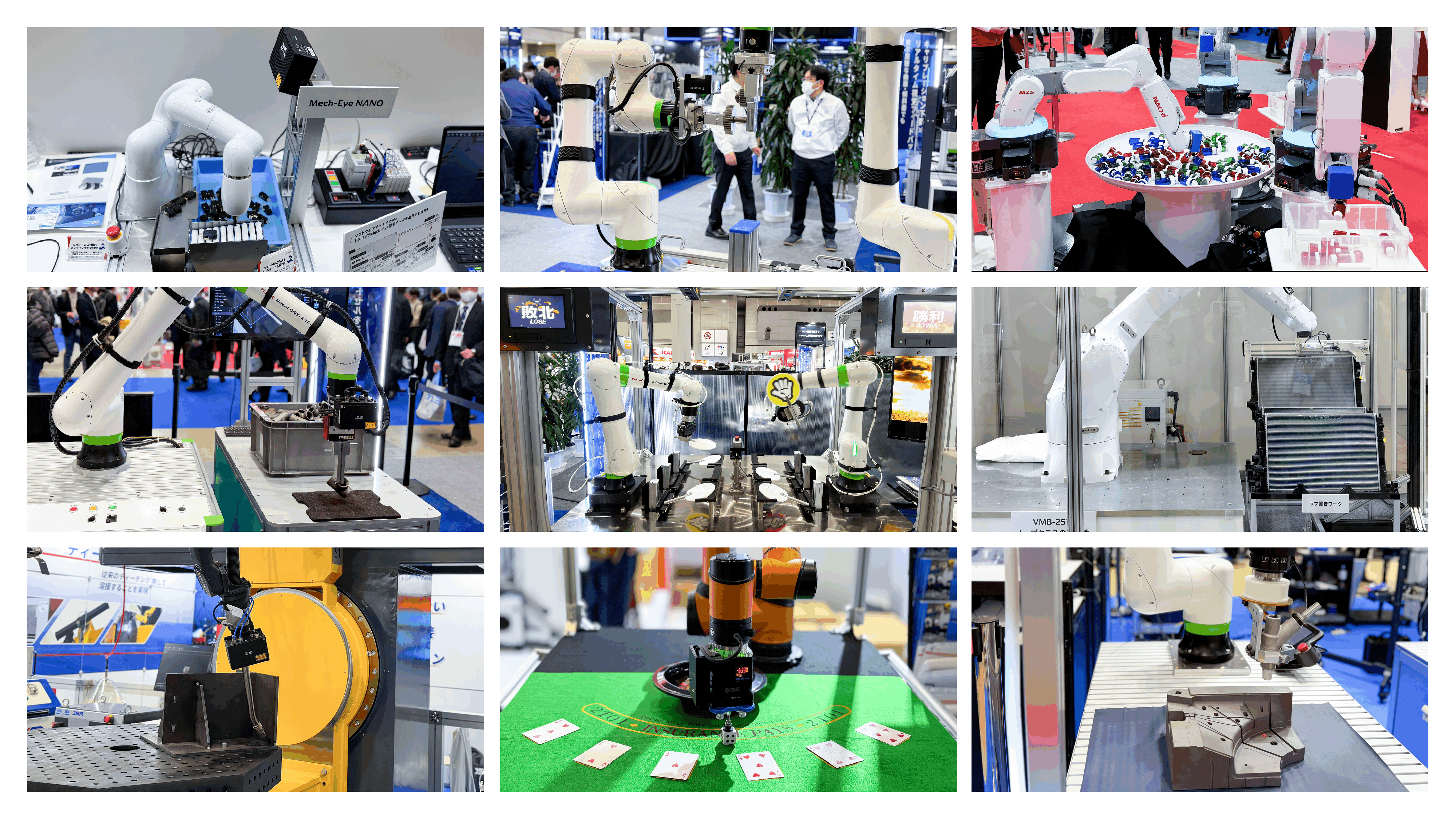

Mech-Mind marked its fourth appearance at iREX with one of the largest stands at the exhibition—a 360-square-meter booth showcasing the company's extensive range of products and applications. On site, Mech-Mind showcased its full-stack embodied-intelligence "Eye-Brain-Hand" for robots—high-precision 3D cameras ("Eye"), AI software suites ("Brain"), and dexterous robotic hands ("Hand"). Additionally, Mech-Mind unveiled several major self-developed products, including a high-performance intelligent 2D camera and an explosion-proof 3D camera engineered for hazardous environments.

Through nearly twenty embodied-intelligence application units—including autonomous goods picking with a humanoid robot, clothes folding by a dual-arm robot, robotic feeding & assembly, and AI quality inspection—Mech-Mind demonstrated the all-scenario capability of its general-purpose robot "Eye-Brain-Hand" across automotive, metal & machining, electronics, and other industries, as well as in home and service settings. Mech-Mind also showcased broad ecosystem collaborations with multiple partners to explore additional application possibilities for embodied-intelligence robots.

Click to watch the video.

01 From Production Lines to Everyday Life: "Eye-Brain-Hand" Unlocks Diverse Scenarios

• Autonomous Goods Picking with a Humanoid Robot

This unit demonstrated Mech-Mind's intelligent humanoid retail solution for shelf goods picking. A full-size wheeled humanoid robot equipped with Mech-Mind's general-purpose robot "Eye-Brain-Hand" can generalize object recognition and precisely manipulate real products in bottles, bags, and boxes, completing order receipt, item retrieval and delivery as a fully autonomous workflow.

The solution offers strong generalization and environmental adaptability, making it well suited to supermarkets, retail stores, research institutions, exhibition venues, and similar settings. As a highly integrated, standardized unit, it supports reception, customer interaction, guided tours, and vending services.

• Clothes Folding by a Dual-Arm Robot

Powered by Mech-Mind's self-developed "Eye + Brain" system, the dual-arm robot demonstrates human-like perception, decision-making, and planning. It autonomously and efficiently executes long-sequence, complex, and flexible tasks that require delicate handling of deformable garments. In the on-site folding demo, the robot determined the task logic, planned the workflow, and executed the full sequence—from picking up the garment and smoothing out wrinkles to folding and tidying the edges—completing a complex end-to-end task without human intervention.

• High-Precision Picking of Transparent Objects

Using Mech-Mind's self-developed 3D and 2D cameras together with AI software, the "Eye + Brain" system autonomously recognizes highly transparent objects with sub-millimeter accuracy, determines front/back orientation, and—through intelligent grasp planning and precise motion control—achieves accurate pick-and-place. This capability addresses common transparent-object handling and sorting needs in both consumer and industrial scenarios.

02 Proven in Industry: Achieving Large-Scale Deployments of "Eye + Brain"

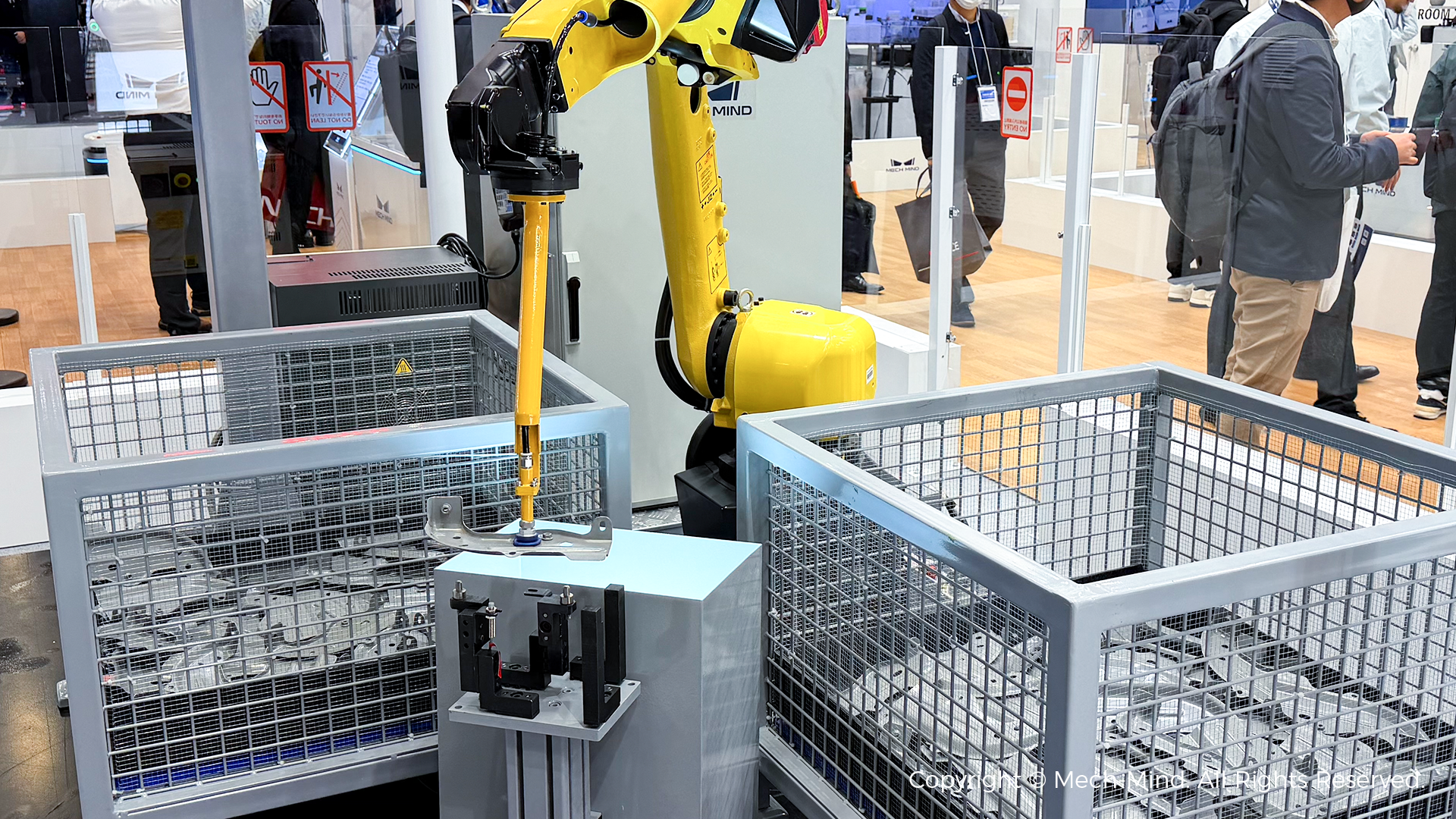

• High-Precision Bin Picking of Sheet-Metal Parts

Based on the embodied-intelligence "Eye + Brain" system, robots identify thin-edged, reflective, irregularly shaped, and randomly stacked sheet-metal parts from a distance, autonomously plan collision-free grasping paths, and complete precise feeding tasks in complex deep-bin environments. Pick accuracy, cycle time, and bin-clearance rate meet production requirements, and the solution has been deployed at scale across automotive and other industries.

• High-Precision Assembly of Splines

Using the "Eye + Brain" system, robots autonomously pick highly reflective, structurally complex external splines from bins and perform high-precision locating of internal splines for precise alignment and rapid assembly. Two Mech-Eye high-precision 3D cameras work together to substantially improve assembly efficiency.

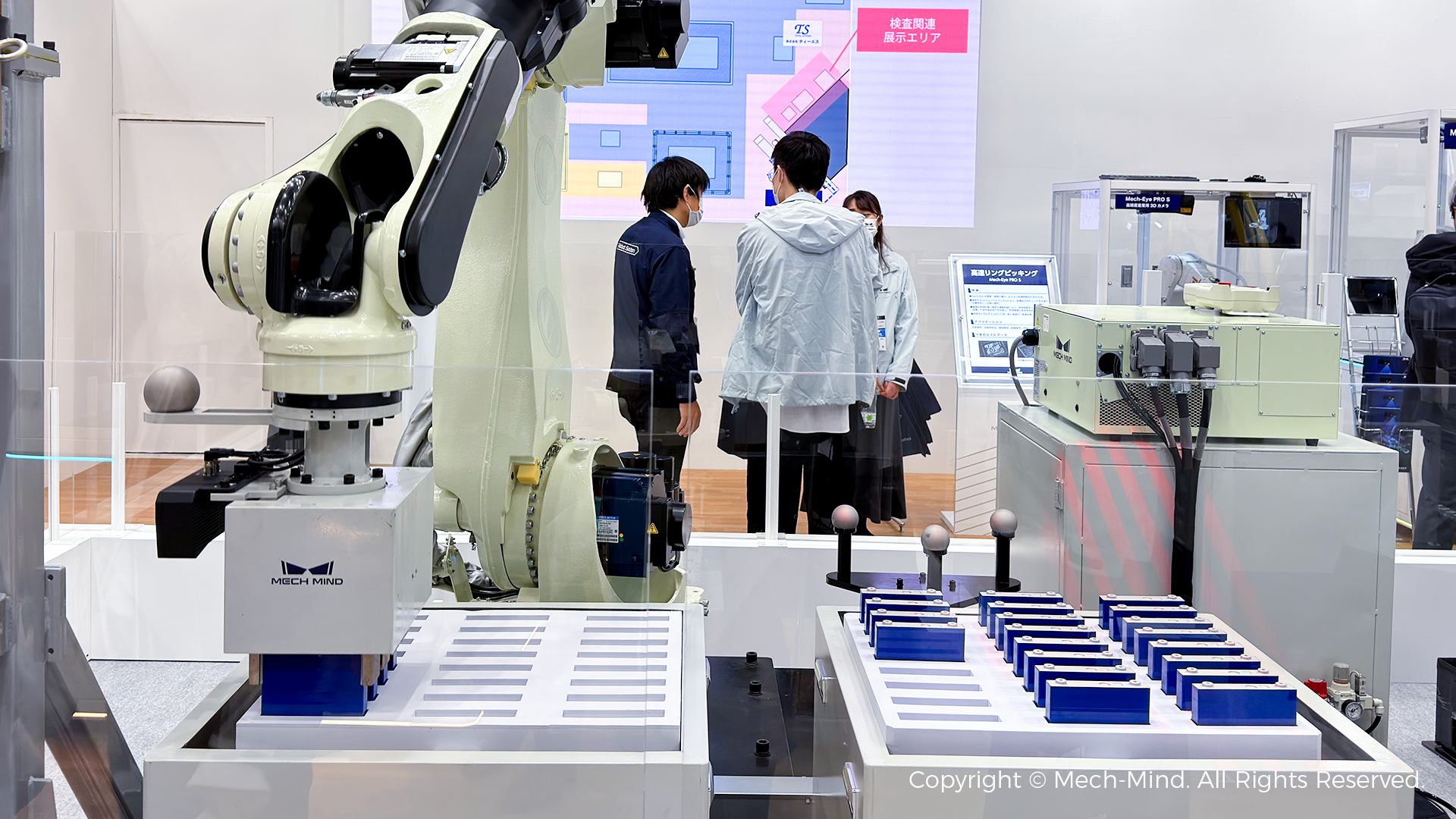

• High-Speed Picking of Small Rings

Built on the general-purpose "Eye + Brain" for robots, the system handles randomly stacked, thin-edged, reflective small rings at cycle times of down to 1.5 seconds per piece. Intelligent path and grasp planning significantly improve bin-clearance rates to meet automatic picking, feeding, and sorting needs for small parts in automotive, home-appliance, and other industries.

• High-Precision Depalletizing of Battery Cells

By integrating the Mech-Eye LSR XL-GL ultra-long-range 3D camera with the Mech-Eye PRO S-GL high-precision 3D camera, Mech-Mind meets the dual demands of wide field of view (FOV) and high accuracy required for large-range battery-cell depalletizing and large-package loading, substantially improving operational accuracy and throughput.

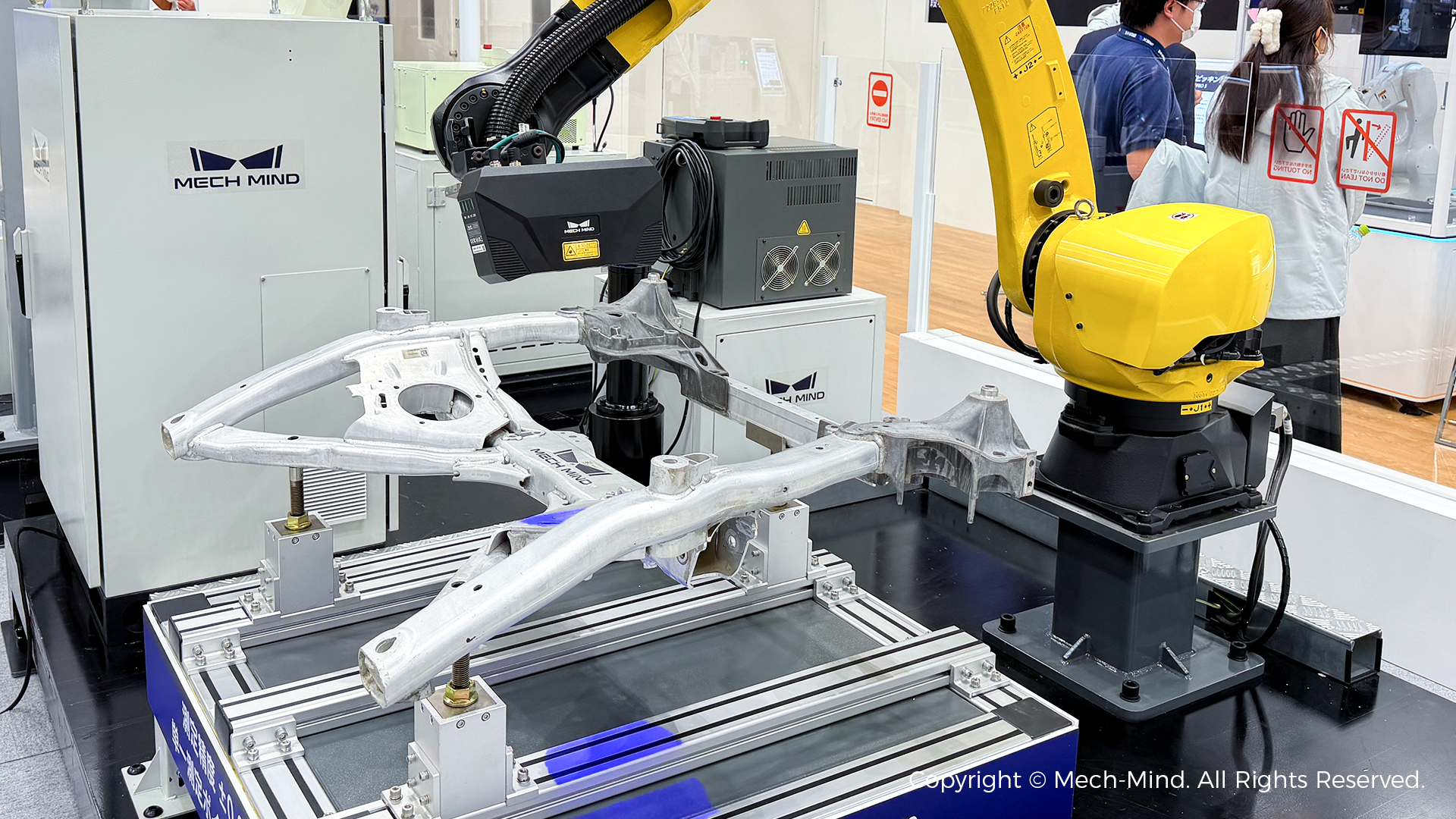

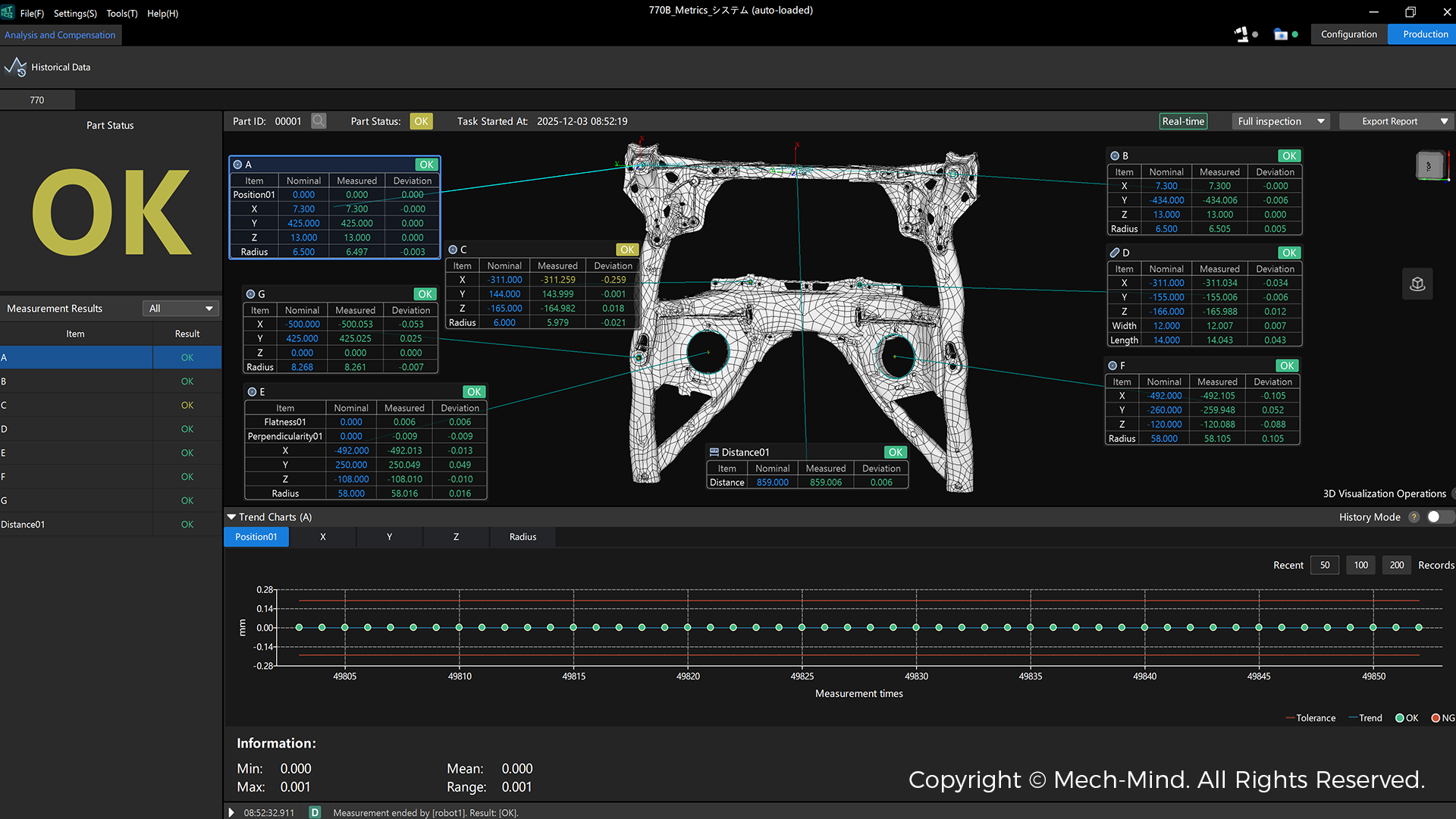

• Inline Measurement of Subframes

On-site photo

Production interface

The Mech-Eye UHP-140-GL 3D Camera with micron-level accuracy integrated with Mech-Vision and Mech-Metrics software, performs rapid, high-accuracy inline measurements of multiple key subframe features. Measurement accuracy reaches ±0.2 mm, and measurement speed can be as fast as 2 seconds per measuring position. The flexible system is already deployed at scale across major OEMs and parts suppliers.

• Connector Pin Inspection

On-site photo

Production interface

The Mech-Eye LNX-8030-GL 3D Laser Profiler, featuring 4K resolution and a 15 kHz scan rate, generates high-resolution 3D point clouds of fine, densely packed pins. With Mech-MSR 3D Measurement and Inspection Software, the solution delivers fast, high-precision height measurements and generalizes across different pin types, models, and materials.

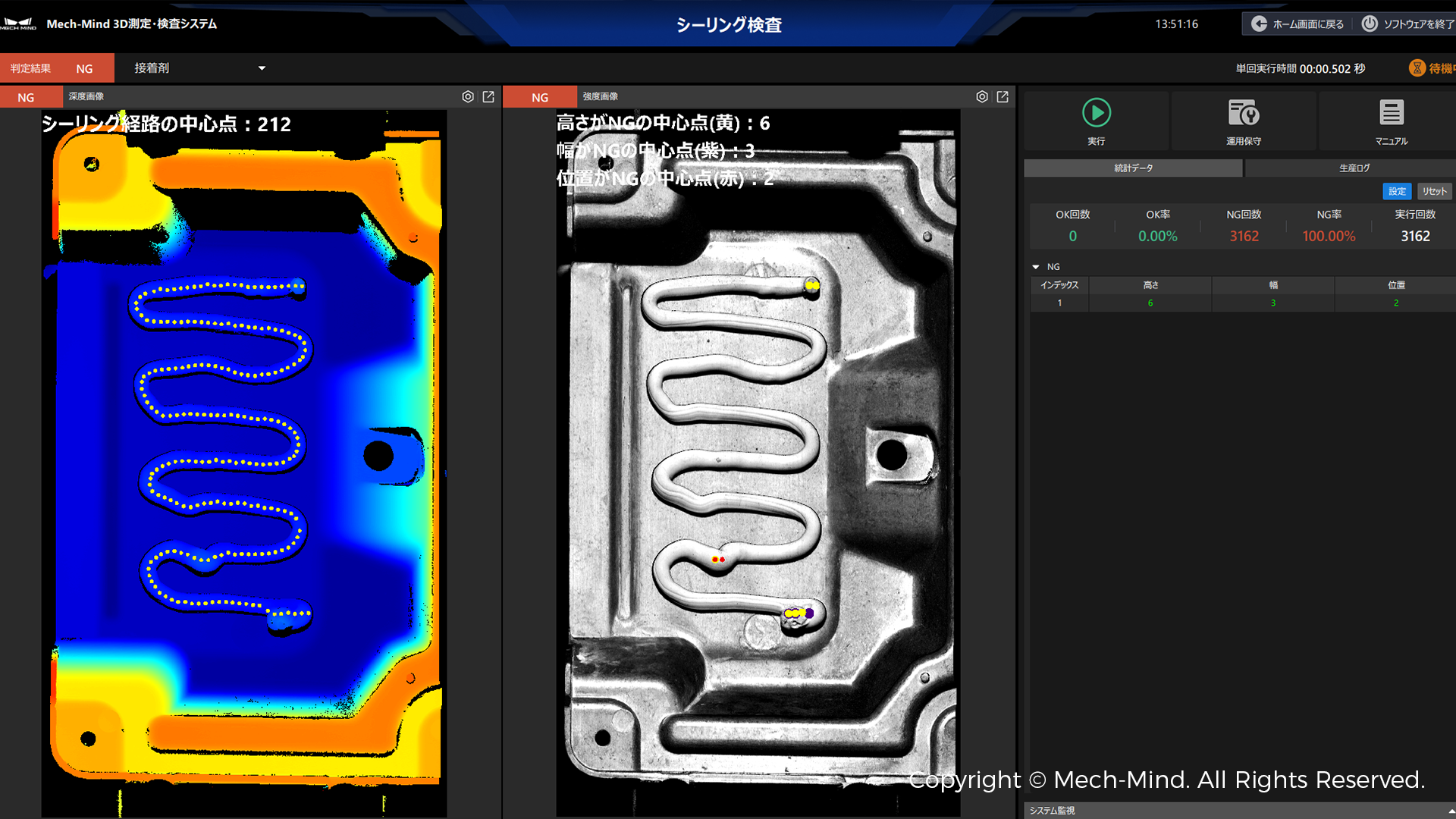

• ECU Glue Bead Inspection

On-site photo

Production interface

The Mech-Eye LNX-7580-GL 3D Laser Profiler, together with Mech-MSR 3D Measurement and Inspection Software, intelligently detects transparent and translucent glue beads, accurately measuring width, height, and position while identifying defects such as bead overflow, breakage, or bubbles to ensure adhesive quality meets production standards.

03 New Products, New Applications: Constantly Expanding Robotic Reach

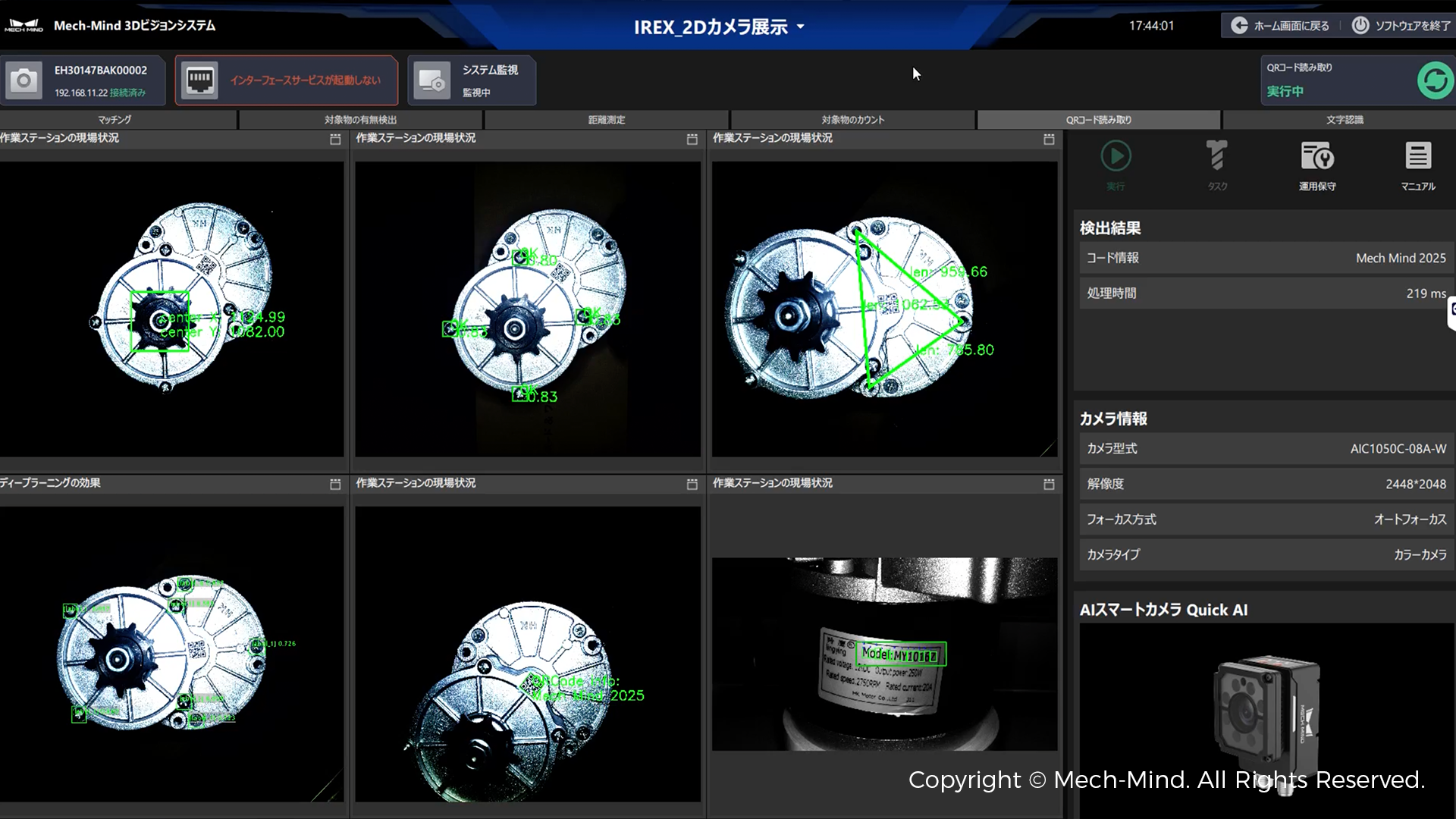

• Small-Motor Character Recognition and Quality Inspection

On-site photo

Production interface

Mech-Mind showcased the newly developed Mech-Eye AIC Intelligent 2D Camera for industrial quality inspection. Paired with Mech-Vision and other intelligent software, the high-performance 2D camera forms a powerful "Eye + Brain" inspection system capable of high-precision character recognition and multidimensional quality inspection, including side OCR, top-side code reading, nut-presence detection, gear center coordinate measurement, and hole-pitch measurement.

This new intelligent 2D camera utilizes self-developed core components and imaging algorithms and is positioned as a flagship product for industrial quality inspection—the official launch is coming soon.

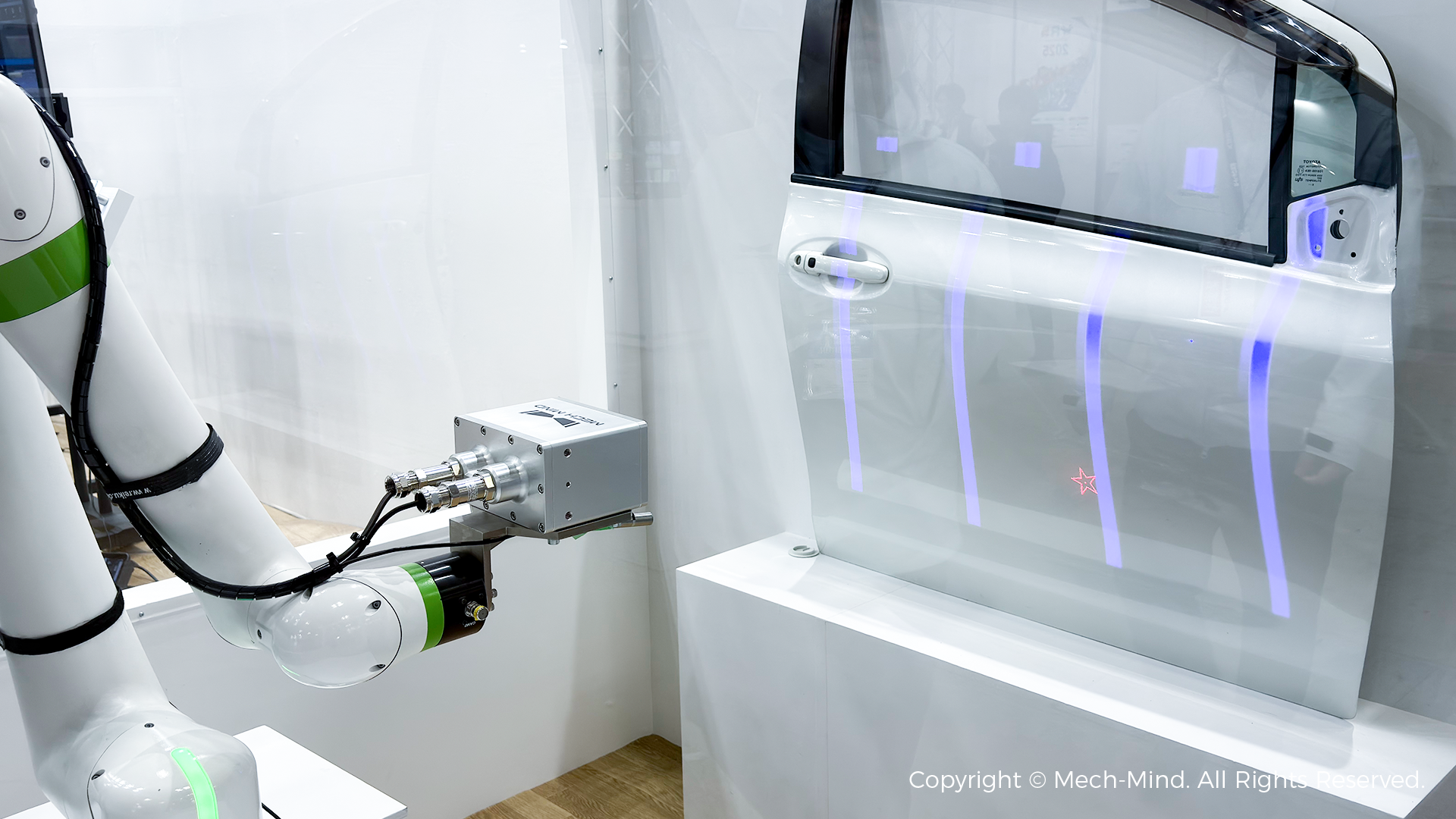

• High-Precision Positioning and Spray-Painting of Automotive Doors

This unit demonstrated a simulated application of the Mech-Eye EPC Paint High-Precision 3D Camera co-developed with partners for automotive-door positioning and spray painting. Featuring a certified explosion-proof housing among other hardware designs, the camera is ideally suited for use in flammable and explosive environments such as automotive spray booths, ship painting facilities, fueling stations, and oil & gas storage/transfer sites.

In real scenarios, the certified housing physically isolates the camera from flammable or explosive environments, enabling safe close-range deployment at spray booths, reducing accuracy loss caused by part mispositioning or long-distance spraying, and minimizing coating waste.

04 Partner Ecosystem Collaboration Showcase

At iREX 2025, Mech-Mind partnered with numerous industry leaders to jointly exhibit more than a dozen intelligent robot application units—including mixed-bolt picking with synchronized inline assembly, depalletizing of transparent totes, and no-teach spraying/polishing/welding—showcasing practical applications of the embodied-intelligence "Eye + Brain" system across manufacturing, logistics, and other industries.

• Mixed-Bolt Picking with Synchronized Inline Assembly

Based on the "Eye + Brain" system, robots accurately identify and pick mixed, randomly stacked small bolts, track and image moving assembly stations with real-time position correction, and complete high-precision dynamic assembly.

Showcase units of Mech-Mind's partners

Mech-Mind has consistently pursued a strategy centered on productization, globalization, and ecosystem development. Today, the company has established over 10 global business centers, with over 17,000 cameras installed in more than 40 countries and regions. To better support local customers in Japan, Mech-Mind established a subsidiary in Tokyo as early as 2021, gradually building a full-cycle customer service network covering sales, delivery, training, and after-sales support. Thanks to the strong product capabilities and comprehensive localized services, Mech-Mind has achieved rapid growth in Japan, forming long-term partnerships with leading robotics companies and system integrators while earning widespread recognition from key customers across multiple industries.

At iREX 2025, Mech-Mind presented the self-developed general-purpose "Eye-Brain-Hand" for robots in Tokyo, offering a comprehensive showcase of the applications across diverse scenarios such as metal & machining, logistics, AI quality inspection, as well as household and service settings. Leveraging deep technological expertise and rapid product iteration, Mech-Mind will soon roll out a series of new robot "Eye-Brain-Hand" products—including intelligent 2D cameras—continuously expanding the application boundaries of general-purpose embodied AI robotics.