In today’s fiercely competitive automotive market, production accuracy and throughput are lifelines for OEMs. To deliver consistent quality at scale and keep up with ever-accelerating production rates, the quality-inspection stage of manufacturing is facing unprecedented challenges. Traditional offline, coordinate measuring machine (CMM)-based inspection workflows are increasingly inadequate: parts are pulled from the line and sent to a metrology lab for slow, sample-based measurement and analysis. That delayed, sample-driven approach can no longer satisfy automakers’ dual demands for high quality and high throughput—it has become a major bottleneck to progress.

Leveraging deep expertise in the general-purpose robot “Eye-Brain-Hand” full-stack technology and extensive industrial manufacturing experience, Mech-Mind has developed an integrated hardware-and-software inline measurement system specifically for the automotive industry. Validated and refined across numerous production lines, the solution is now fully productized and market-ready: customers can deploy it rapidly without lengthy or complex commissioning. The system delivers high-precision, 100% inline inspection of critical dimensions on parts and body assemblies, providing real-time visibility into every component’s quality data and end-to-end traceability across the production process.

01 Powered by Robot “Eye + Brain”—Achieving Ultra-Precise, High-Speed Measurement

In automotive manufacturing, even millimeter-level deviations can cause squeaks, premature wear, or functional failure. Therefore, a measurement system must first and foremost see and measure accurately—detecting minute dimensional deviations and ensuring correct assembly.

Mech-Mind 3D Vision Inline Measurement—Core Components

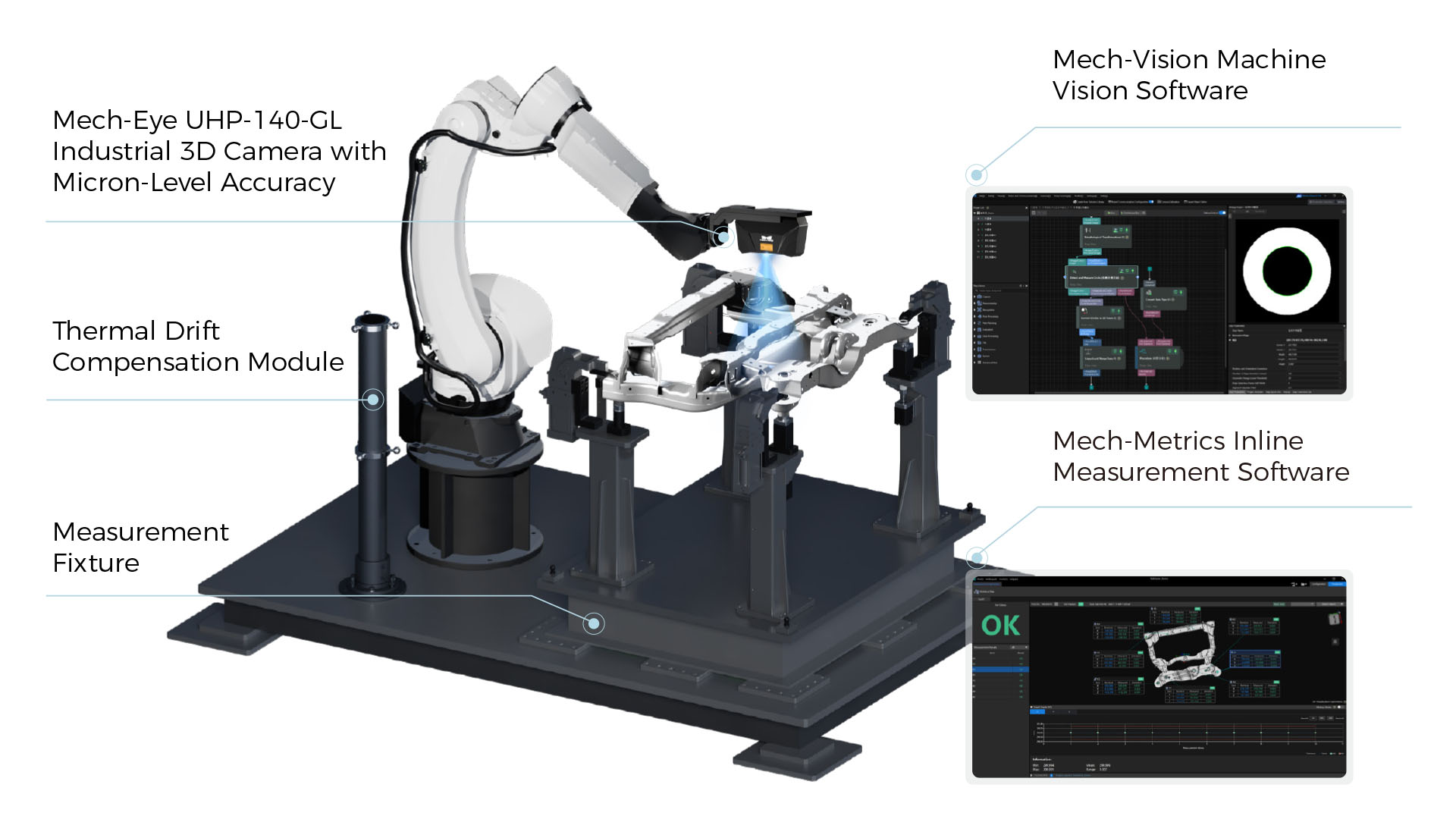

Mech-Mind 3D Vision Inline Measurement System integrates the self-developed Mech-Eye UHP-140-GL Industrial 3D Camera with Mech-Vision Machine Vision Software, Mech-Metrics Inline Measurement Software, and other high-performance hardware and software components.

Acting as the system’s “eye,” the Mech-Eye UHP-140-GL uses advanced anti-reflective and image-fusion AI algorithms to handle reflective surfaces, complex geometries, and occlusions while capturing 3D feature data with ultra-high precision.

Acting as the system’s “brain,” Mech-Vision and Mech-Metrics embed robust AI vision and 3D-measurement algorithms validated on large industrial datasets to perform recognition, measurement, and analysis.

The point clouds (color-rendered by height) are generated by the Mech-Eye UHP-140-GL 3D camera with micron-level accuracy.

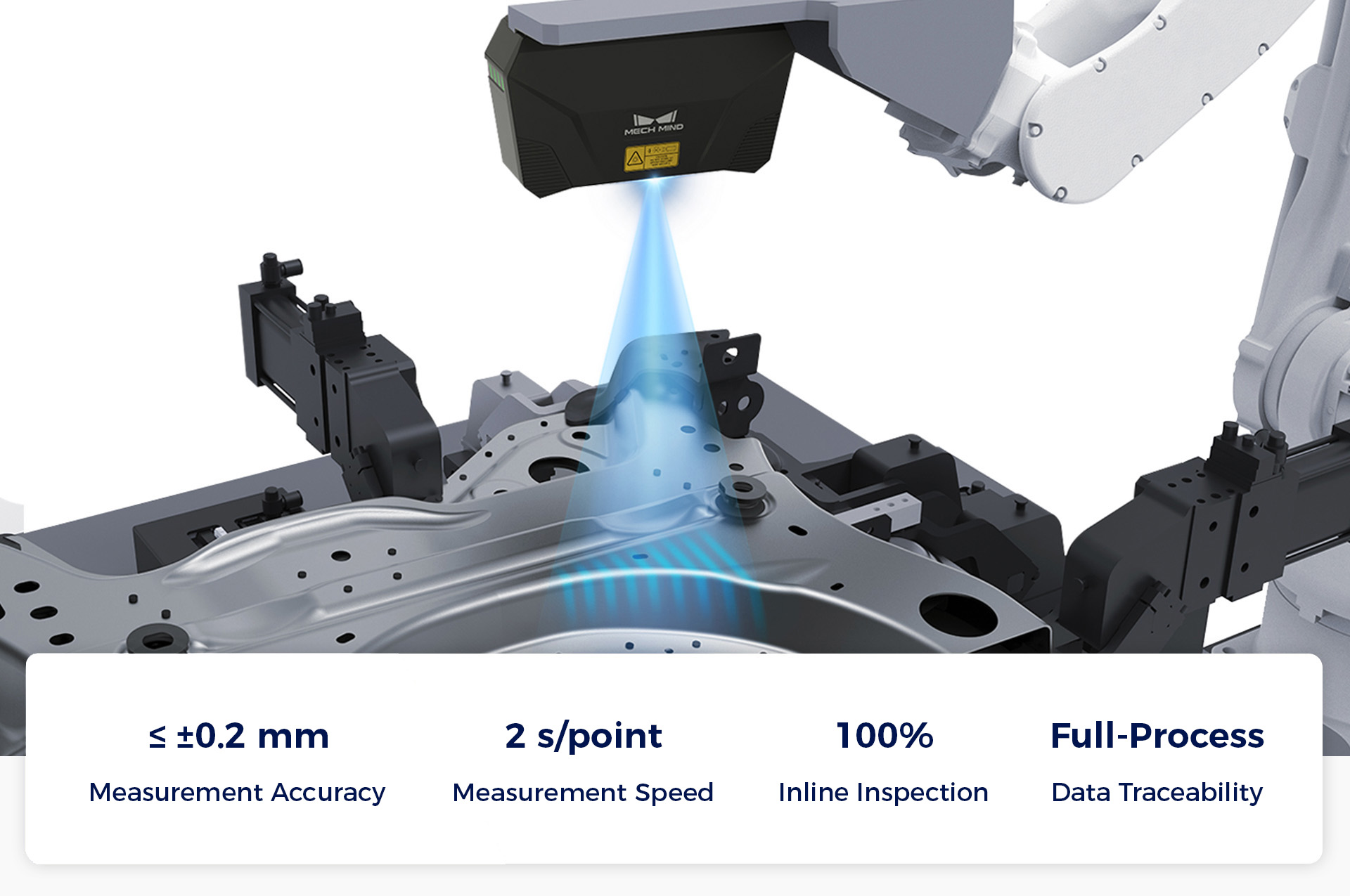

Deep hardware-software integration and efficient "Eye + Brain" collaboration let the system intelligently identify features and perform precise fitting calculations, delivering CMM-comparable accuracy with deviations consistently within ±0.2 mm.

To mitigate accuracy drift from ambient temperature changes, the inline measurement system includes a self-developed thermal-drift compensation module that dynamically calibrates measurements—reducing environmental thermal drift, minimizing unplanned downtime due to measurement error, and markedly improving production continuity and stability.

Accuracy alone isn’t enough—measurement must also be fast. Thanks to optimized measurement logic and the "capture-and-move" mode—which allows the robot to start moving immediately after each image capture—Mech-Mind’s inline measurement system can measure a single point in as little as 2 seconds, cutting measurement time by more than 90% compared with traditional methods. This enables high-precision, 100% inline inspection without slowing the production line, delivering quality and throughput in parallel.

02 100% Inline Inspection—Full-Process Data Traceability and Closed-Loop Quality Management

The Mech-Mind 3D Vision Inline Measurement System can be integrated directly into high-speed production lines to inspect every workpiece and every vehicle in real time. This shifts the industry away from random sampling: any dimensional drift or assembly error is detected and flagged on the line, preventing batch-level quality incidents.

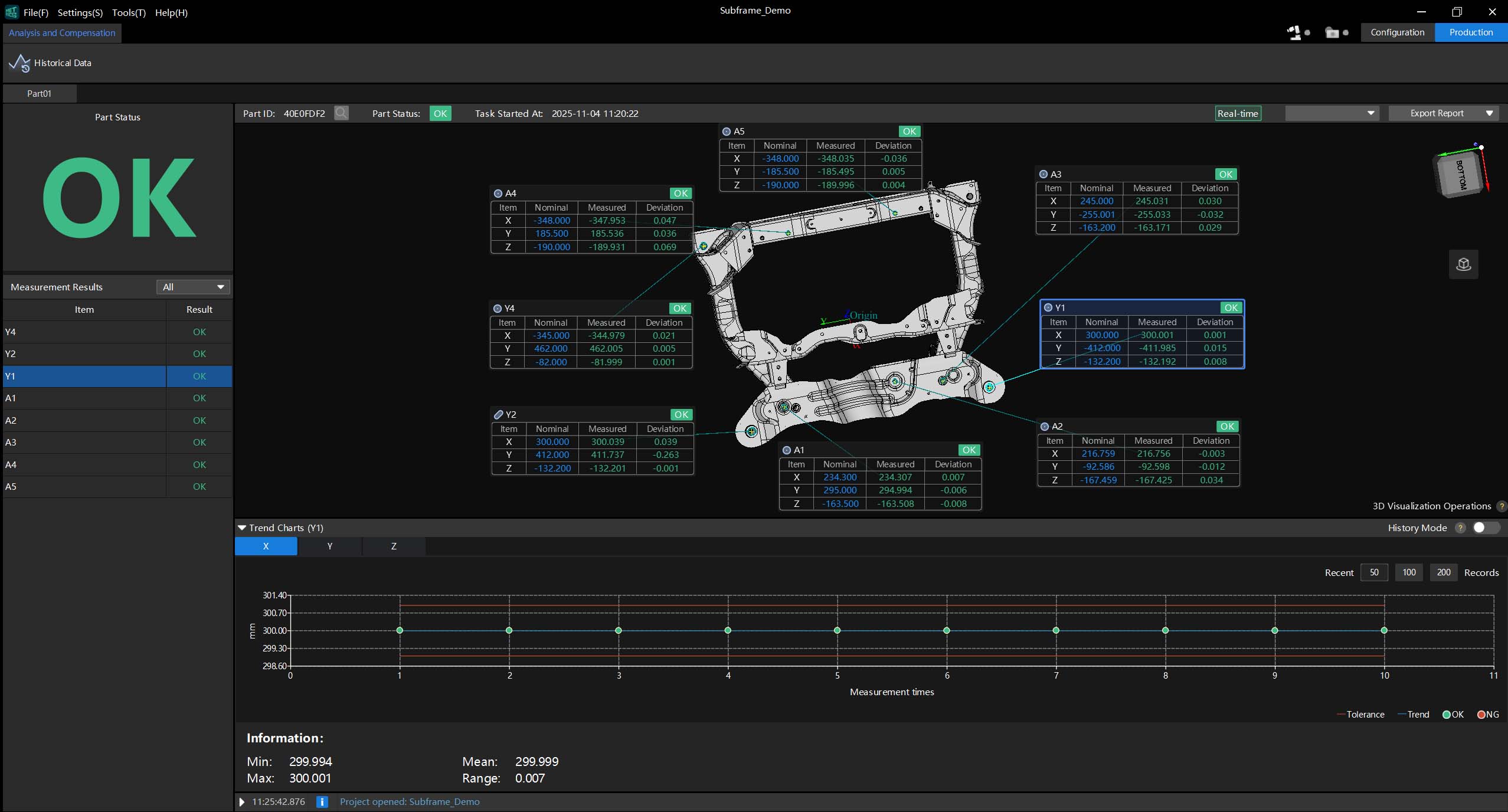

Mech-Metrics outputs measurement results in real time and records every key dimensional data point for each part. When a quality issue arises, users can trace from serial number to production batch, timestamp, and even workstation—enabling precise root-cause localization.

Mech-Metrics also performs in-depth mining and statistical analysis of historical measurement data and automatically generates SPC (statistical process control) reports that visualize quality trends. Quality engineers can anticipate risks, proactively adjust process parameters, and resolve issues earlier. Measurement shifts from a line-end task to becoming the engine that drives continuous process optimization and sustained quality improvement.

Production interface (Mech-Metrics)

03 Rapid Deployment, Flexible Changeovers—Maximizing Business Value

After extensive project experience and iterative product development, Mech-Mind has distilled complex measurement technology into a highly standardized, productized solution. The system supports deep hardware-software coordination and pre-tuning, greatly reducing on-site installation and commissioning. Compared with highly customized, project-based implementations, the standardized system can shorten deployment cycles by more than 50%, substantially lowering both the technical barrier and the time-to-deploy.

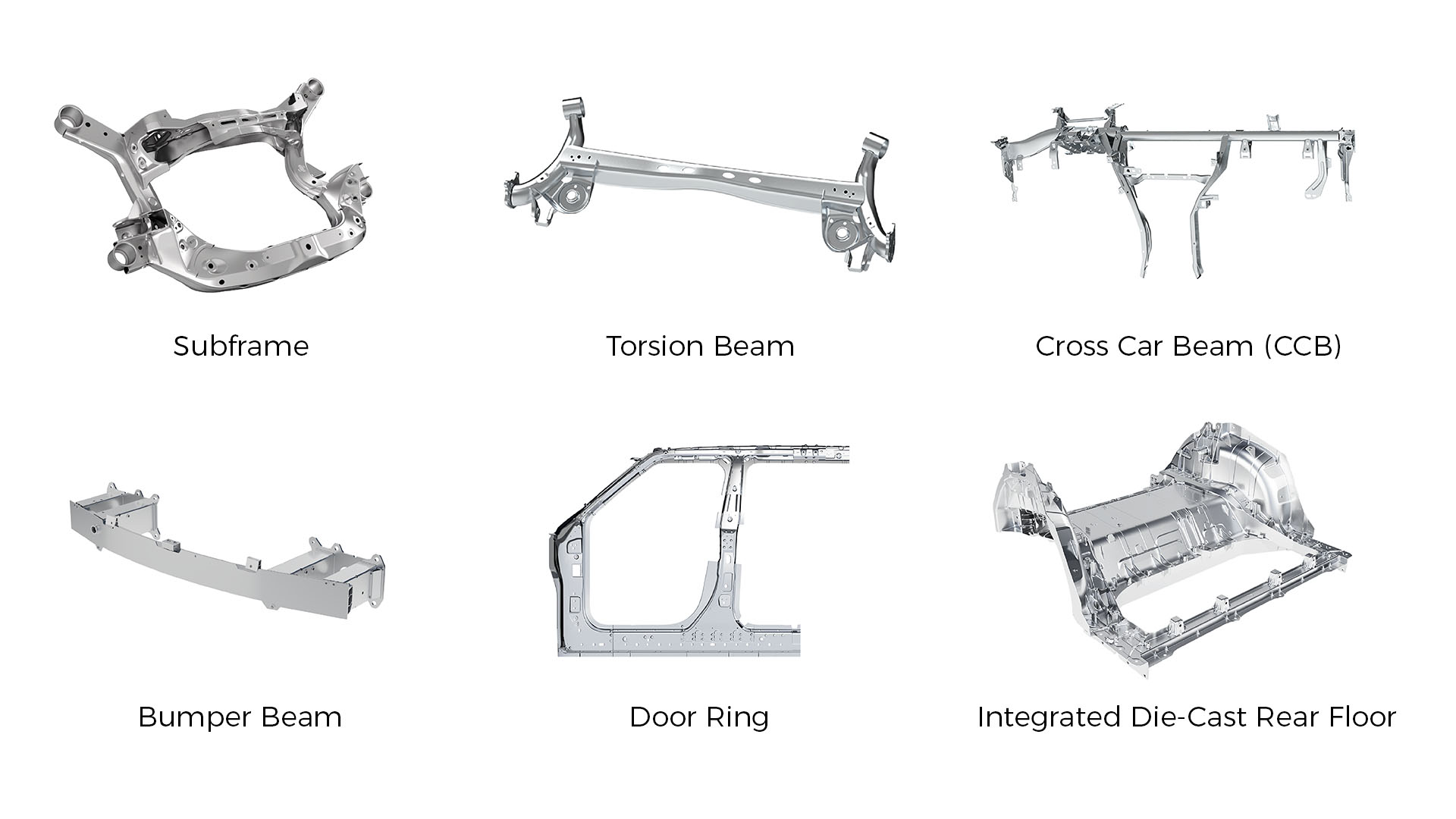

Mech-Mind’s inline measurement system adapts to core automotive production stages from component manufacturing to sub-assembly welding. It performs high-precision measurement across components, subassemblies, and full assemblies and is compatible with different product models and inspection features—such as round holes, slotted holes, threaded holes, and studs—helping automakers realize rapid, flexible changeovers.

Mech-Mind’s inline measurement system flexibly adapts to diverse typical workpieces.

The system accurately measures geometric dimensions of key features (length, width, diameter, etc.) as well as geometric tolerances (position, flatness, surface profile, etc.).

Application Cases

With stable, industry-proven performance, the Mech-Mind 3D Vision Inline Measurement System has been deployed at scale across leading OEMs and Tier-1 suppliers worldwide, covering stamping, welding, final assembly, and component manufacturing and assembly—comprehensively supporting improvements in production efficiency and product quality.

• Large automotive OEM—Front/Rear Subframe and Left/Right Control-Arm Inline Measurement

Front subframe inline measurement

Rear subframe inline measurement

Left & right control arm inline measurement

To meet high-speed, high-precision inline measurement requirements for front and rear subframes and left/right control arms, Mech-Mind delivered a mature system that helped the customer build an efficient, flexible production line. The system seamlessly supports multiple workpiece types, enables rapid changeovers and mixed-model production, and not only ensures precise end-to-end inline measurement and quality control but also significantly boosts overall line efficiency and competitiveness.

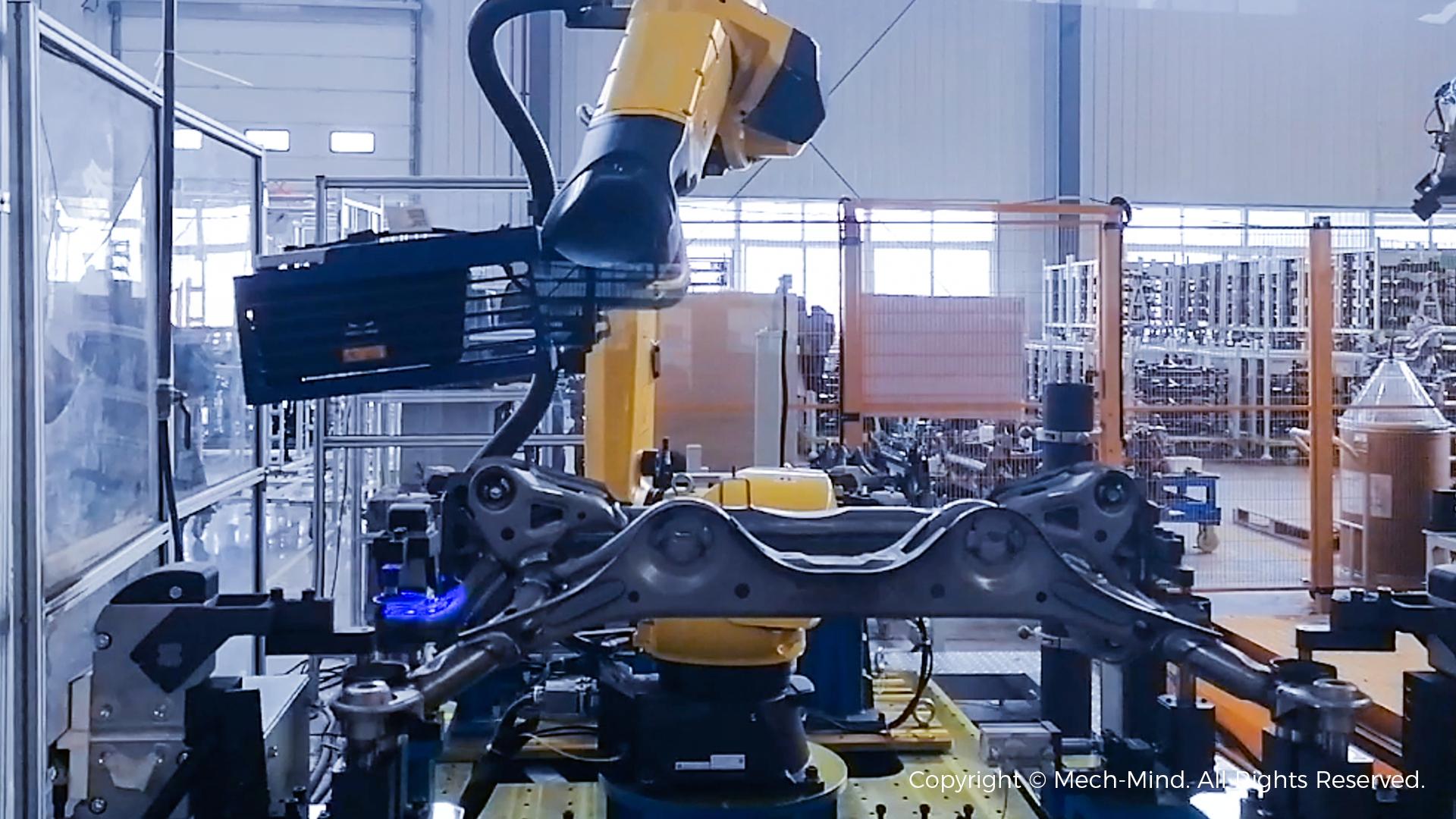

• Large Automotive Parts Supplier—Subframe Inline Measurement

On site, the customer required high-precision measurement of dozens of subframe features, including positional tolerances and surface profiles. Mech-Mind’s highly flexible system demonstrated excellent adaptability and reliably completed high-precision measurements of features such as round holes and studs.

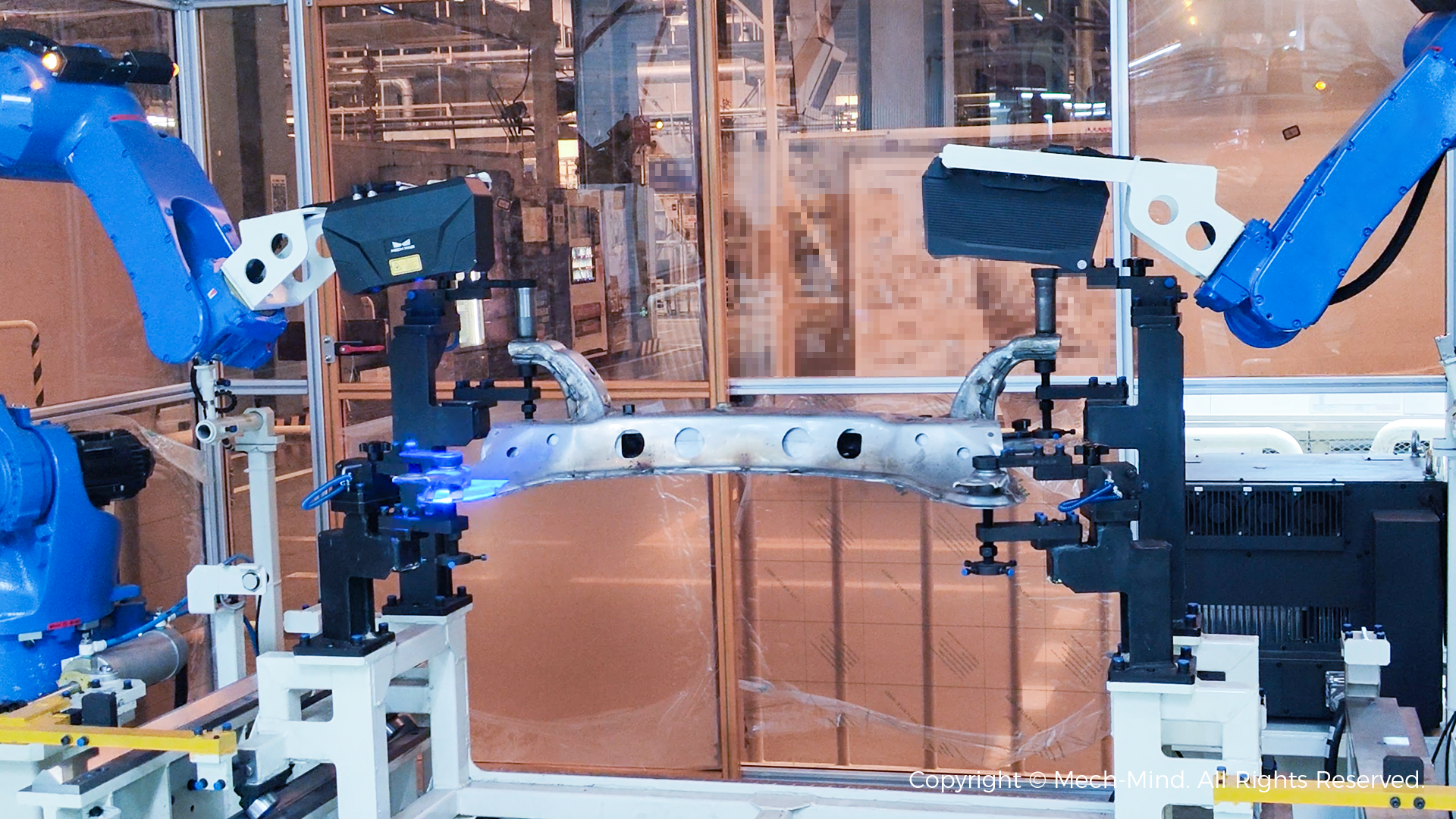

• Large Automotive Parts Supplier—Torsion Beam Inline Measurement

As a critical suspension component, the torsion beam’s compact geometry and complex surfaces create visual occlusions that make traditional measurement inefficient and incomplete. Using self-developed AI algorithms, Mech-Mind’s inline measurement system enabled robots to autonomously plan measurement paths, intelligently avoid interference, and efficiently capture key features. After deploying the system, the customer realized higher measurement efficiency and data reliability, shortened cycle times, and an overall uplift in line performance.

• Large Automotive Parts Supplier—Cross Car Beam (CCB) Inline Measurement

Faced with CCB’s complex geometry and reflection-induced poor imaging and 3D data loss, Mech-Mind’s advanced anti-reflection AI algorithms overcame imaging interference to ensure accurate feature positioning and measurement. The system delivered high-precision measurement under challenging conditions, substantially improving measurement stability and production throughput to safeguard high-quality output.

After extensive real-world deployments with OEMs and suppliers worldwide, Mech-Mind 3D Vision Inline Measurement System has become increasingly mature and stable in performance while accumulating rich project delivery experience. Mech-Mind is well positioned to provide integrators and partners with end-to-end support in technology, products, delivery, and training. Going forward, Mech-Mind will continue to refine measurement technology and deepen industry expertise, helping more automakers achieve closed-loop, full-process quality management and accelerate their intelligent-manufacturing transformation.