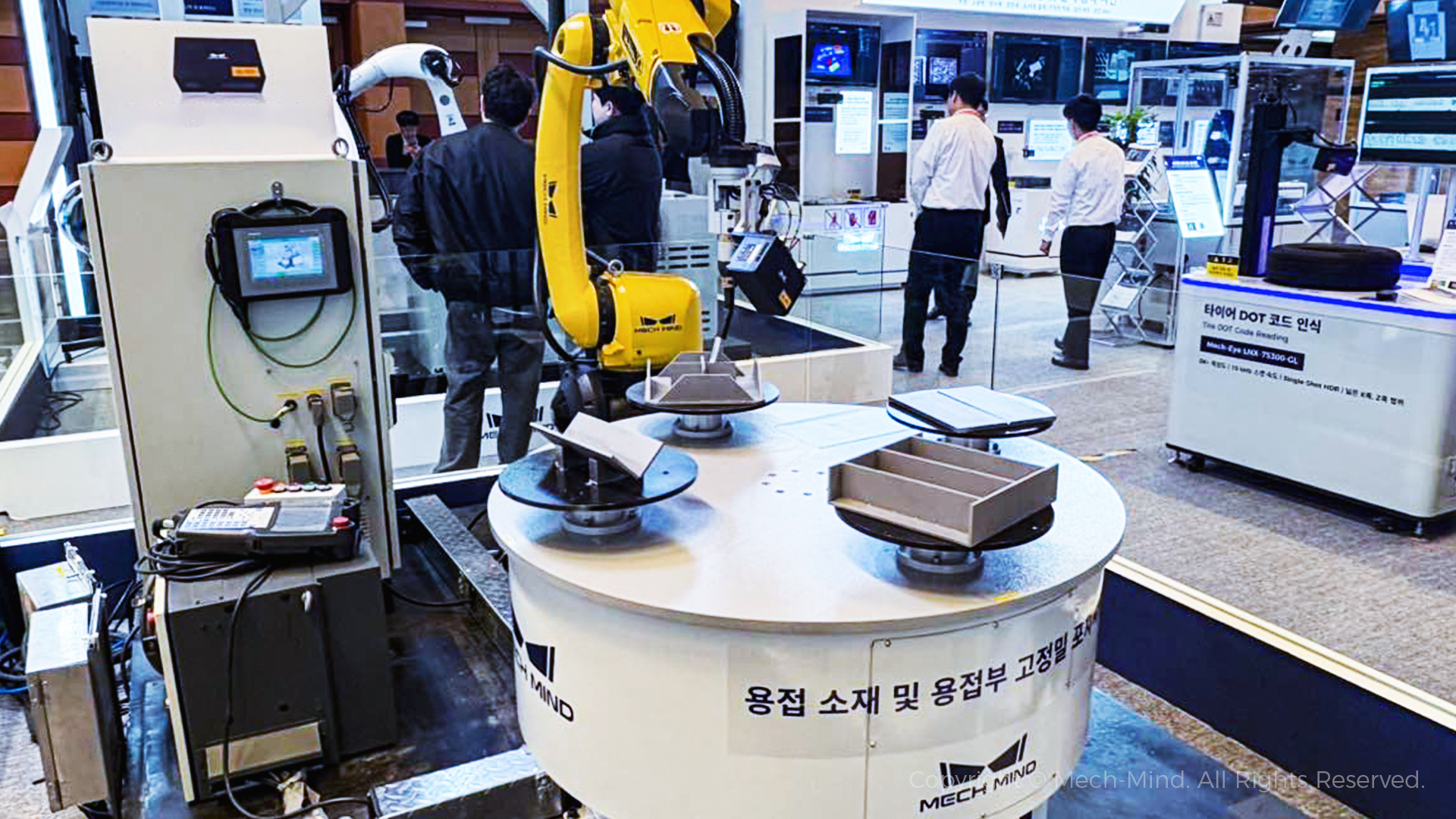

Mech-Mind’s booth at SF + AW 2025

From March 12 to 14, the Smart Factory and Automation World 2025 (SF + AW 2025) was held at the Convention and Exhibition Center in Seoul, Korea. As one of the largest and most influential robotics and automation exhibitions in Asia, this year’s event attracted over 500 leading companies from around the world. More than 80,000 professional visitors were expected, setting a new attendance record.

After one year, Mech-Mind returned with the latest AI + 3D vision solutions, advancing smart manufacturing with cutting-edge robotics and automation innovations. Mech-Mind showcased 10+ AI + 3D vision solutions for applications in automotive manufacturing, precision welding, home appliance assembly, and industrial quality inspection, attracting numerous professionals to visit and exchange ideas.

Click to watch the video.

01 Advanced Vision-Guided Robotic Applications

1. AI + 3D Vision-Guided High-Precision Shock Absorber Assembly

● Two robotic arms and multiple 3D cameras enable precise shock absorber assembly. Two Mech-Eye PRO M-GL cameras scan the parts in the bins, while one Mech-Eye NANO ULTRA-GL focuses on the assembly area. The AI + 3D vision system guides the robot in picking the parts precisely to complete the assembly.

● Advanced imaging algorithms deliver complete and detailed point clouds for both dark and reflective surfaces of the parts in a single shot.

● Advanced 3D vision and deep learning algorithms enable precise recognition of disordered stacked parts and high-accuracy positioning of assembly features.

● Intelligent path planning and collision detection algorithms optimize the robotic motion in real time, maximizing the efficiency of collaborative assembly.

2. AI + 3D Vision-Guided Bin Picking of Sheet Metals

● The self-developed Mech-Eye LSR XL-GL industrial 3D camera, engineered for long-range applications, generates detailed 3D point clouds of reflective and complex sheet metal parts from a working distance of over 3 meters, providing high-quality imaging of their fine features.

● Mech-Eye LSR XL-GL offers an ultra-wide FOV (field of view) and deep DOF (depth of field), easily handling applications such as picking from deep bins and picking large parts in a single shot.

● Intelligent path planning and collision detection algorithms ensure reliable robotic picking from deep bins without collisions.

3. AI + 3D Vision-Guided Welding

● Mech-Eye NANO ULTRA-GL offers high precision and high resolution, capable of accurately capturing fine details on highly reflective, dark, or rusted weld seams (e.g., V-shaped welds, right-angle welds, etc.).

● Mech-Eye NANO ULTRA-GL has a compact design, making it ideal for installation on robotic arms and collaborative arms, enabling flexible operation in narrow and complex welding environments.

● Featuring an IP65-rated aluminum alloy housing and an optional protective shell with active cooling components, it ensures stable and superior performance in challenging industrial environments with dust, high temperatures, etc.

● Mech-Eye NANO ULTRA-GL supports the positioning of weldments at any angle and posture, greatly improving production flexibility and efficiency.

4. AI + 3D Vision-Guided Random Picking of Small Rings

The AI + 3D vision system can produce clear and detailed 3D point clouds for highly reflective rings with thin outer diameters. The robust algorithm optimizes the picking sequence and strategy based on the different shapes (round or square) of the parts. Rings tightly stacked in the corner and those close to the bin wall are no longer tricky in the vision task. The cycle time is less than 1.9 seconds, fully meeting the speed requirements of actual production.

5. AI + 3D Vision-Guided Random Picking of Small Bolts

The AI + 3D vision system accurately recognizes randomly stacked small bolts, guiding the robot to reliably pick bolts tightly stacked in corners and close to the bin wall. It enables fast and precise picking of small parts, significantly improving production efficiency and processing accuracy.

02 Multi-Scenario AI Quality Inspection Applications

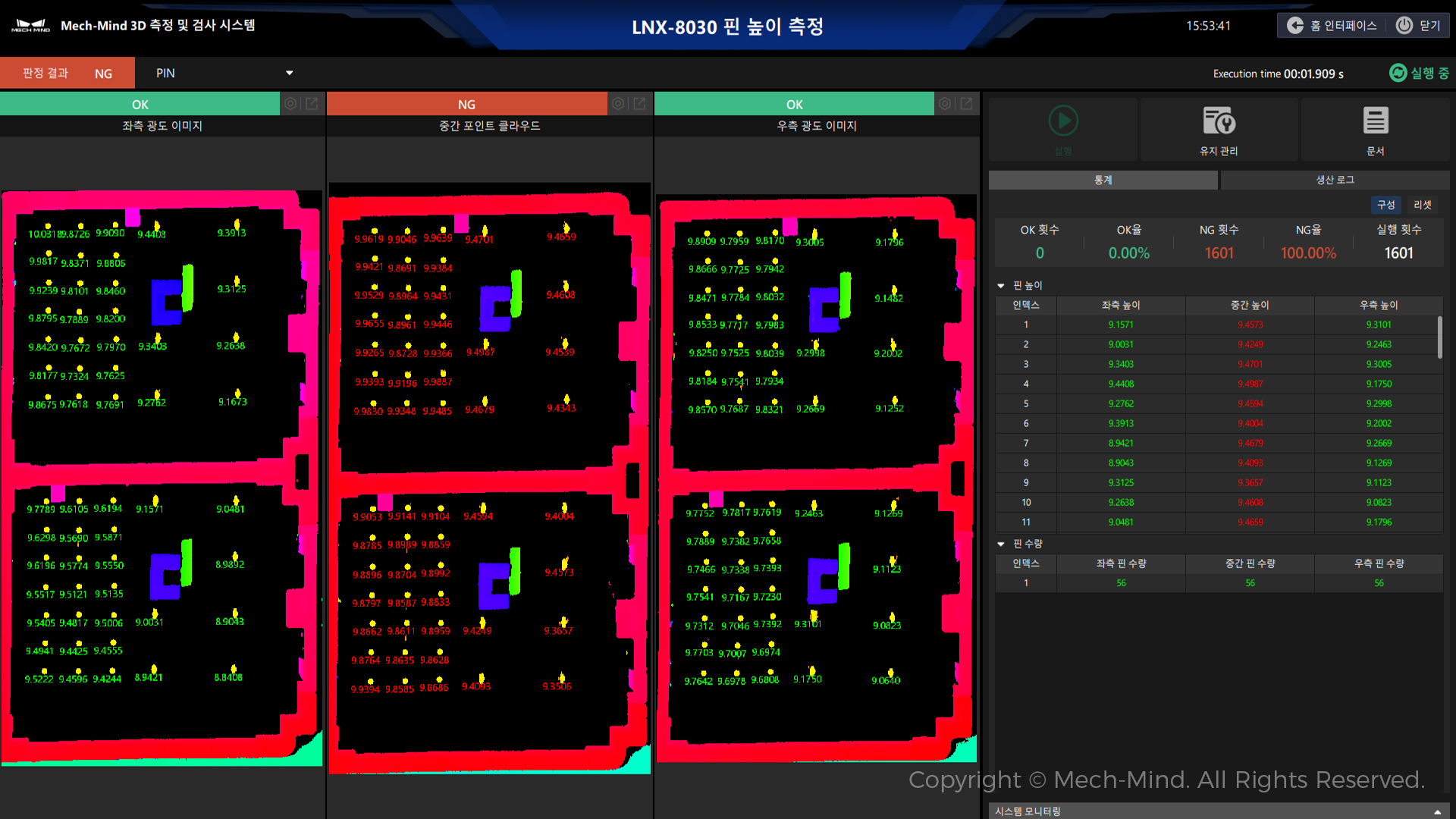

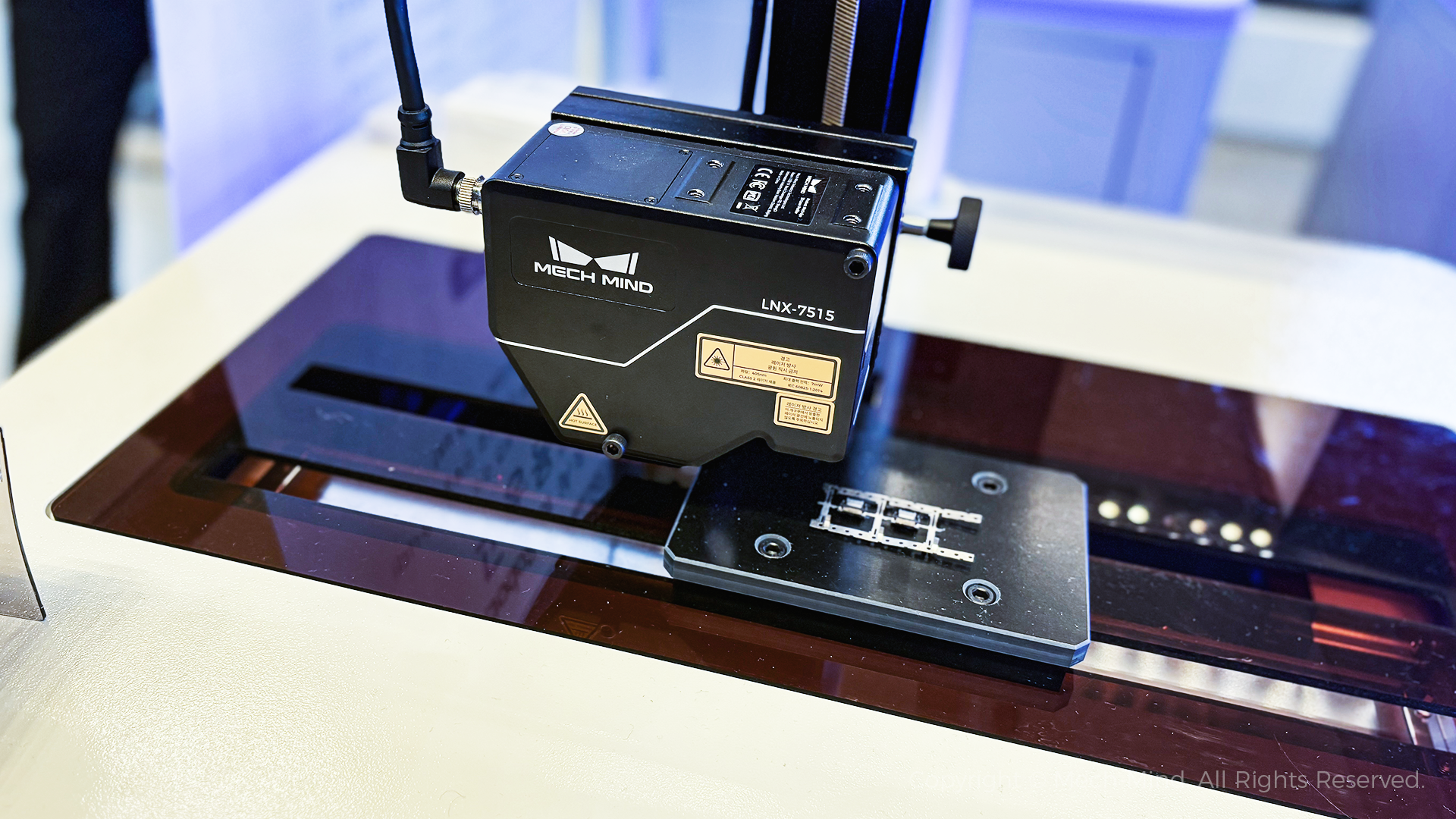

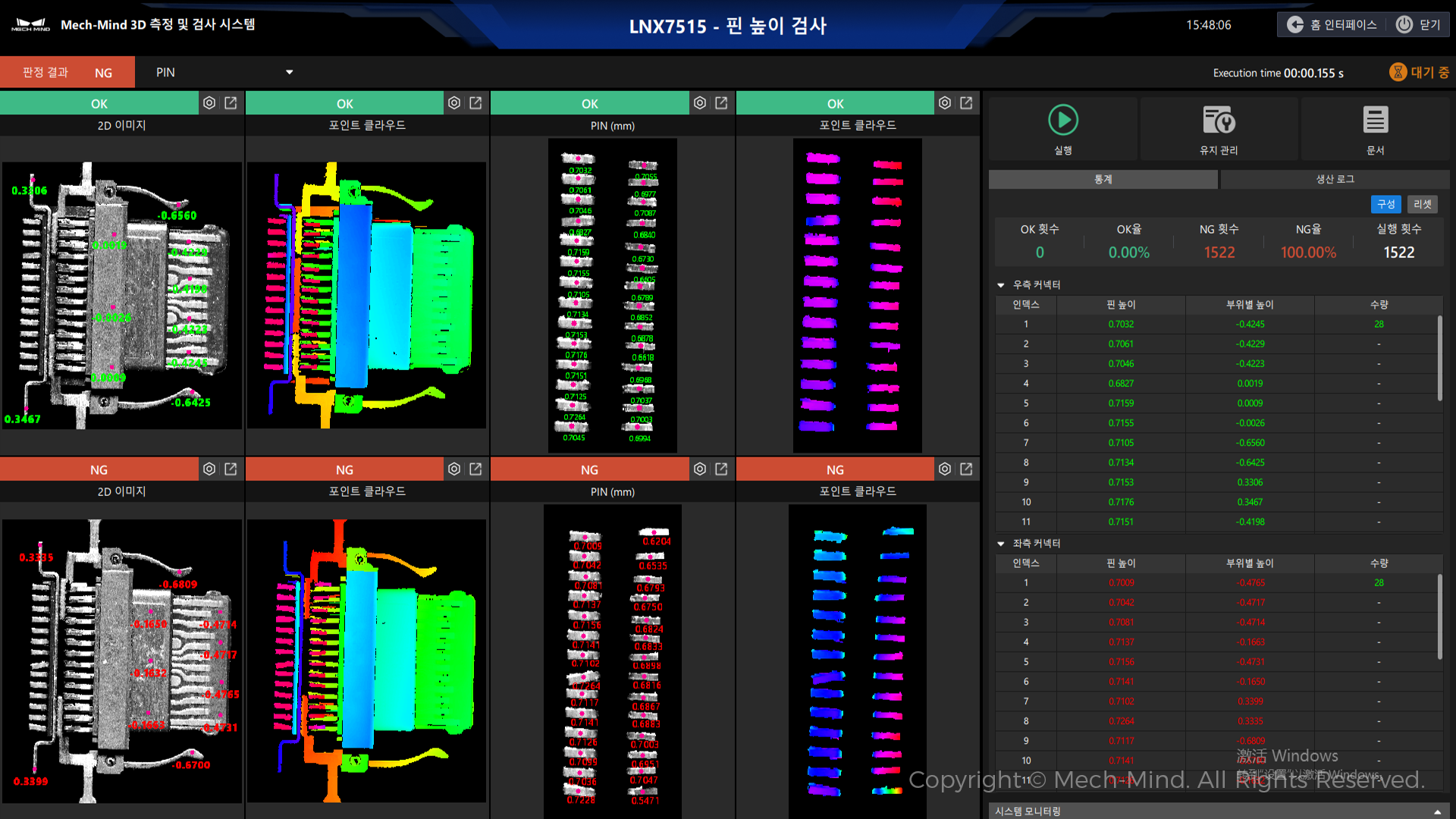

1. Connector Pin Height Measurement

Connector pin height measurement demo

Production interface

The Mech-Eye LNX-8030-GL, with its 4K+ resolution, is capable of precisely extracting the fine features of tiny and closely spaced pins. The Mech-MSR 3D Measurement and Inspection Software, integrated with advanced 3D measurement algorithms, accurately recognizes and extracts pin tips to detect bent pins and height deviations, enhancing product yield.

2. ECU Glue Bead Inspection

ECU glue bead inspection demo

Production interface

Advanced AI imaging technology enables high-quality imaging of highly reflective or translucent glue paths. The self-developed 3D measurement algorithms measure the shape, width, height, and cross-sectional area of the glue paths, detecting discontinuity, overflow, and air bubbles.

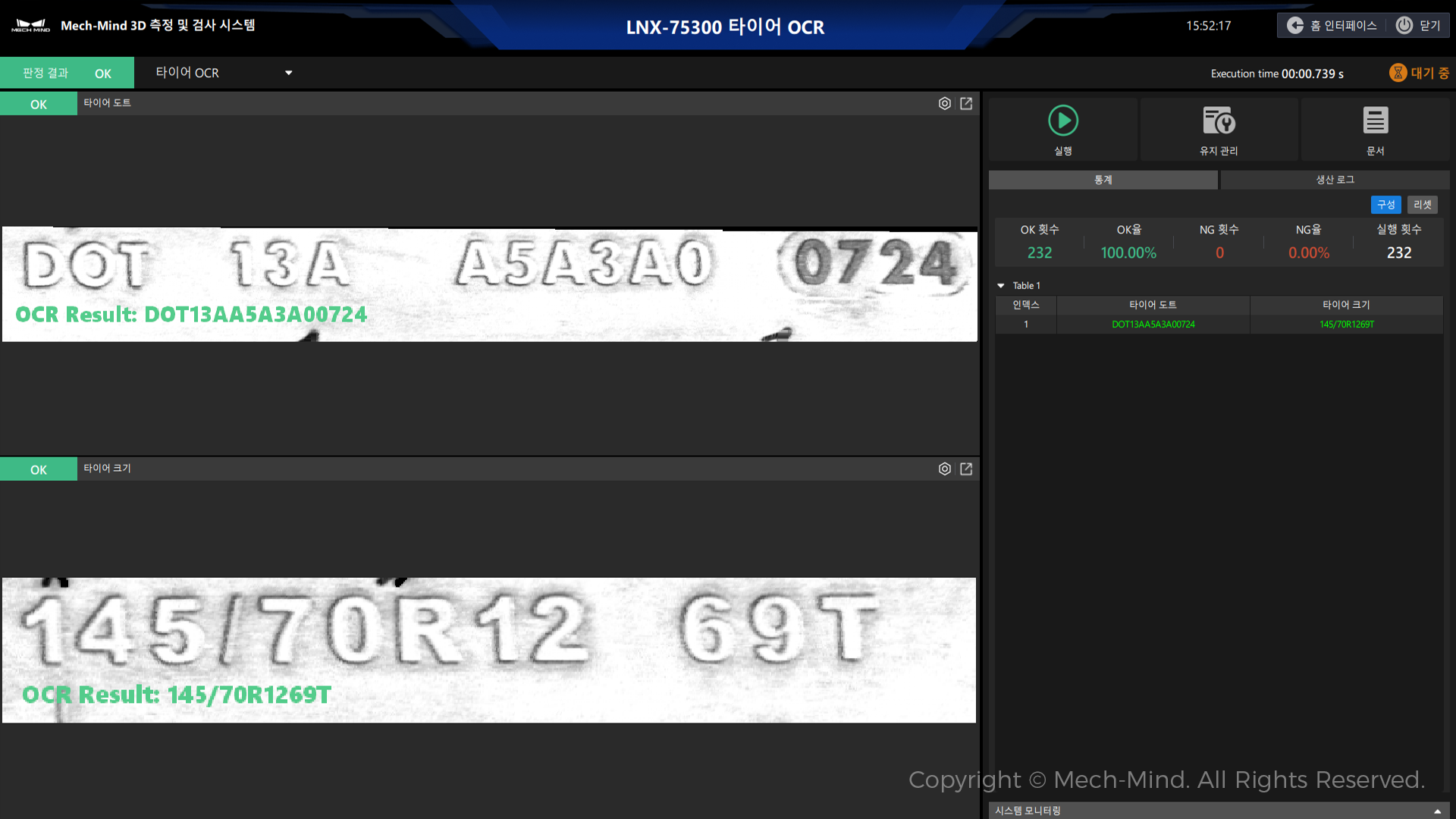

3. Tire DOT Code Reading

Tire DOT code reading demo

Production interface

Engineered with high resolution and a fast scan rate, the Mech-Eye LNX-75300-GL delivers high-efficiency, high-precision inspection for production lines. It has large measurement ranges on the X and Z axes, allowing it to scan large tires in a single shot. Combined with Mech-DLK Deep Learning Software, it effectively handles challenging codes and background interference. Compared to traditional labeling methods, the OCR labeling efficiency is improved tenfold.

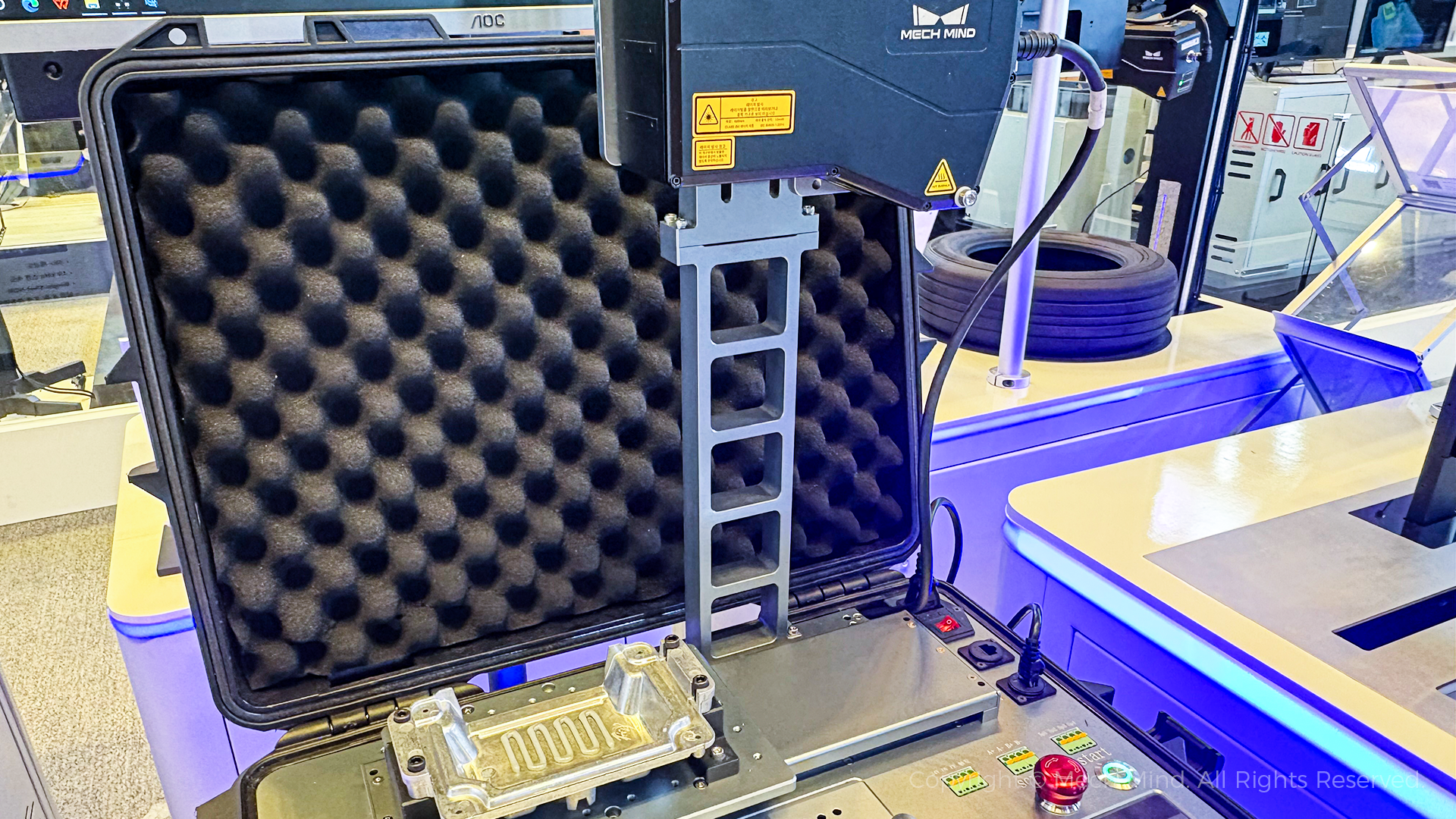

4. Type-C Connector Pin Coplanarity Inspection

Type-C connector pin coplanarity inspection demo

Production interface

The advanced AI imaging algorithms generate detailed 3D point clouds for fine pins, effectively overcoming challenges such as multiple reflections and spikes of the point clouds. The key technical indicators all surpass industry standards with a repeatability under 0.01 mm and a cycle time below 0.8 seconds.

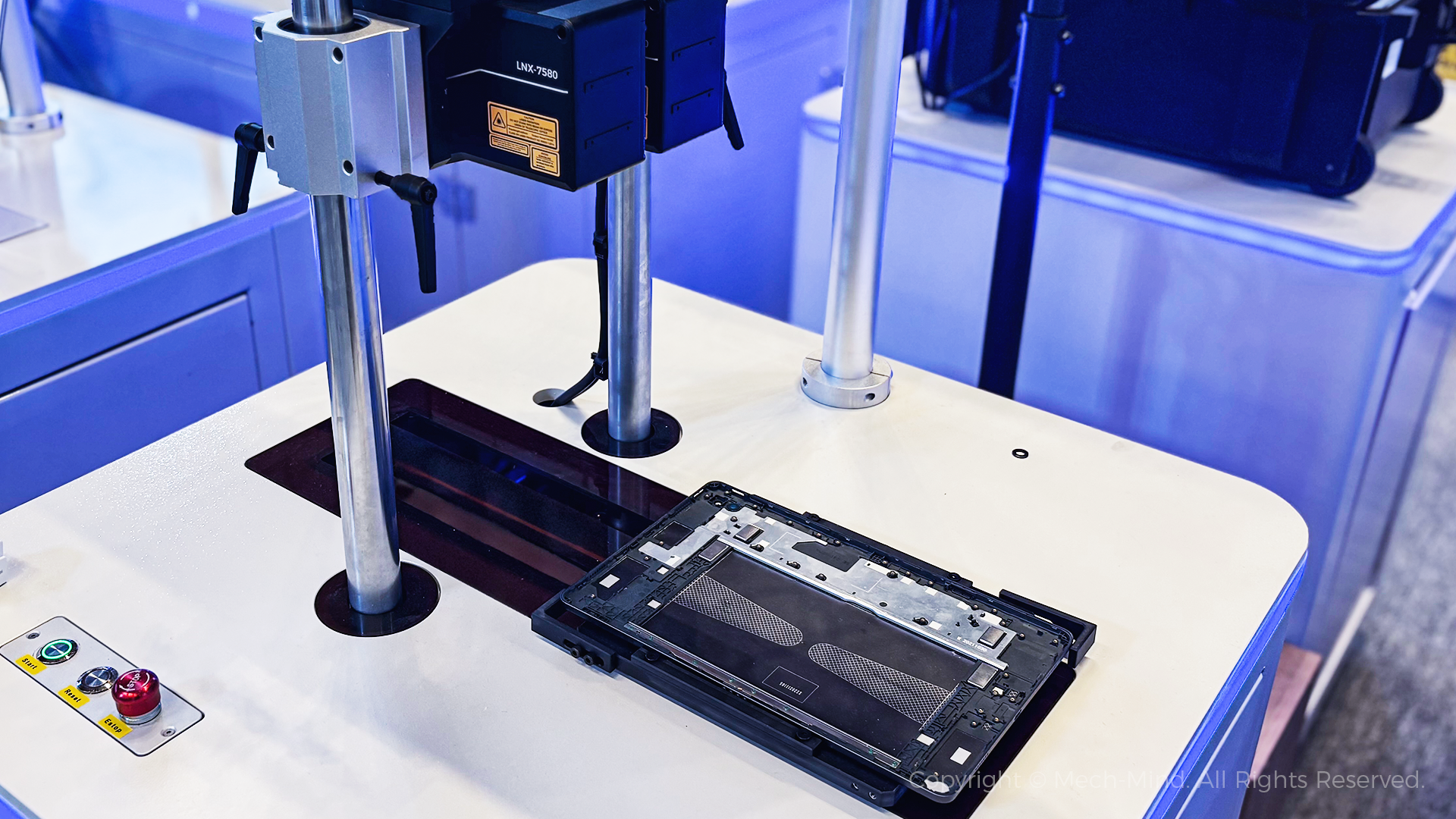

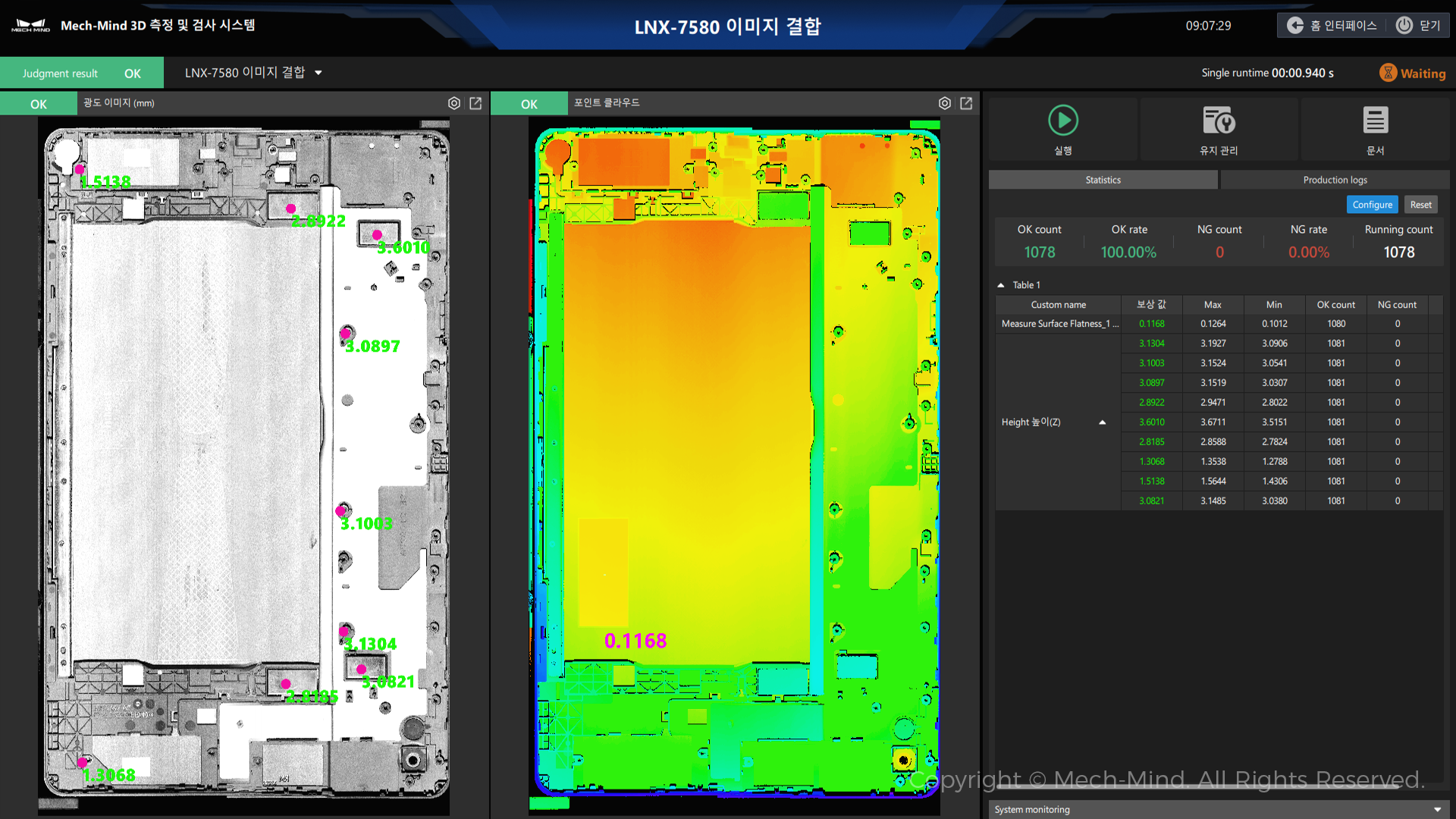

5. Tablet Flatness and Height Measurement

Tablet flatness and height measurement demo

Production interface

Ultra-high resolution and ultra-fast scan rate meet the high-speed and high-quality inspection needs of production lines. The two-camera setup enables high-precision measurements of different regions and parameters of the tablet. The single-shot HDR imaging function allows the sensor to capture both dark and reflective surfaces in a single scan.

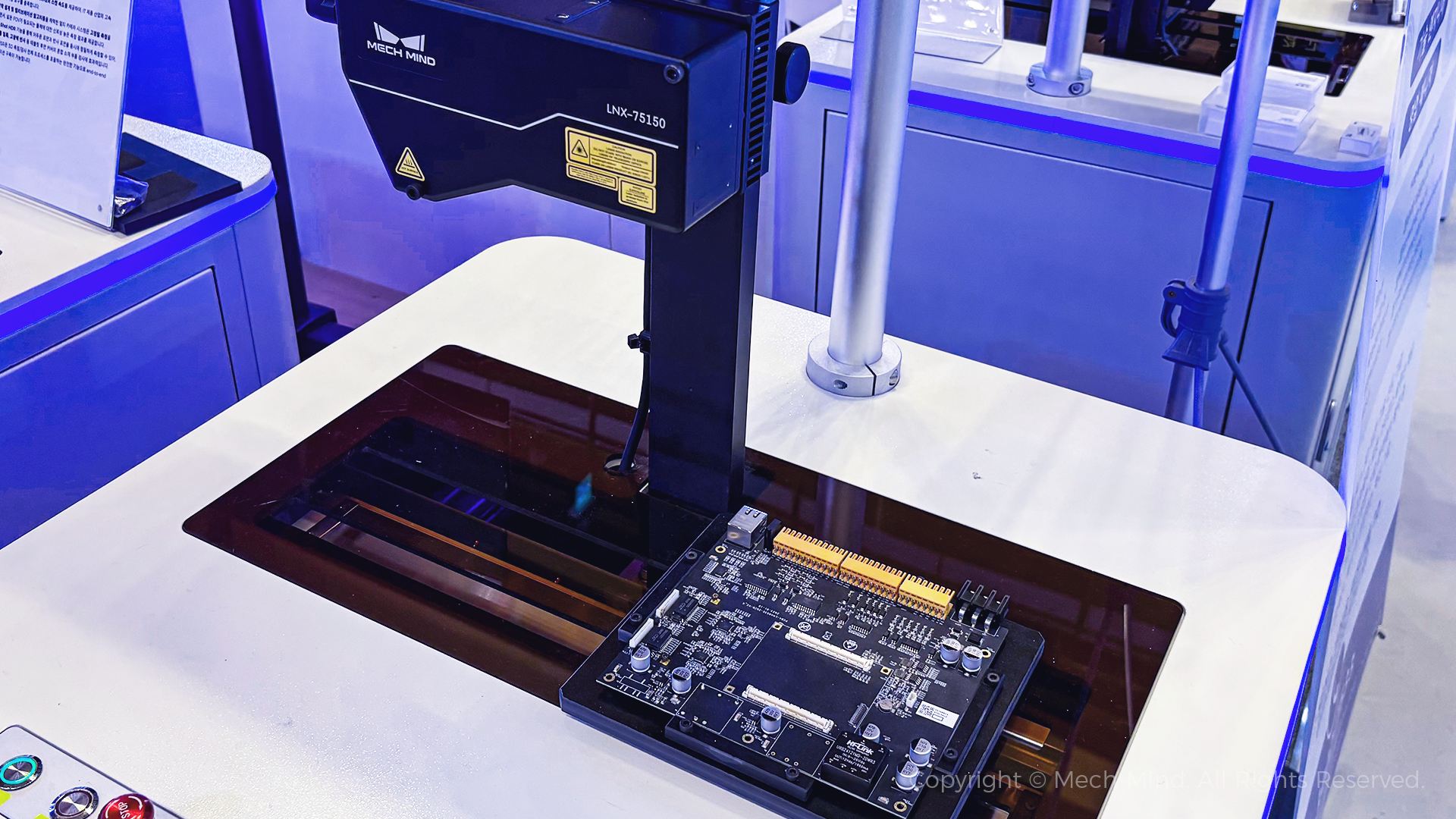

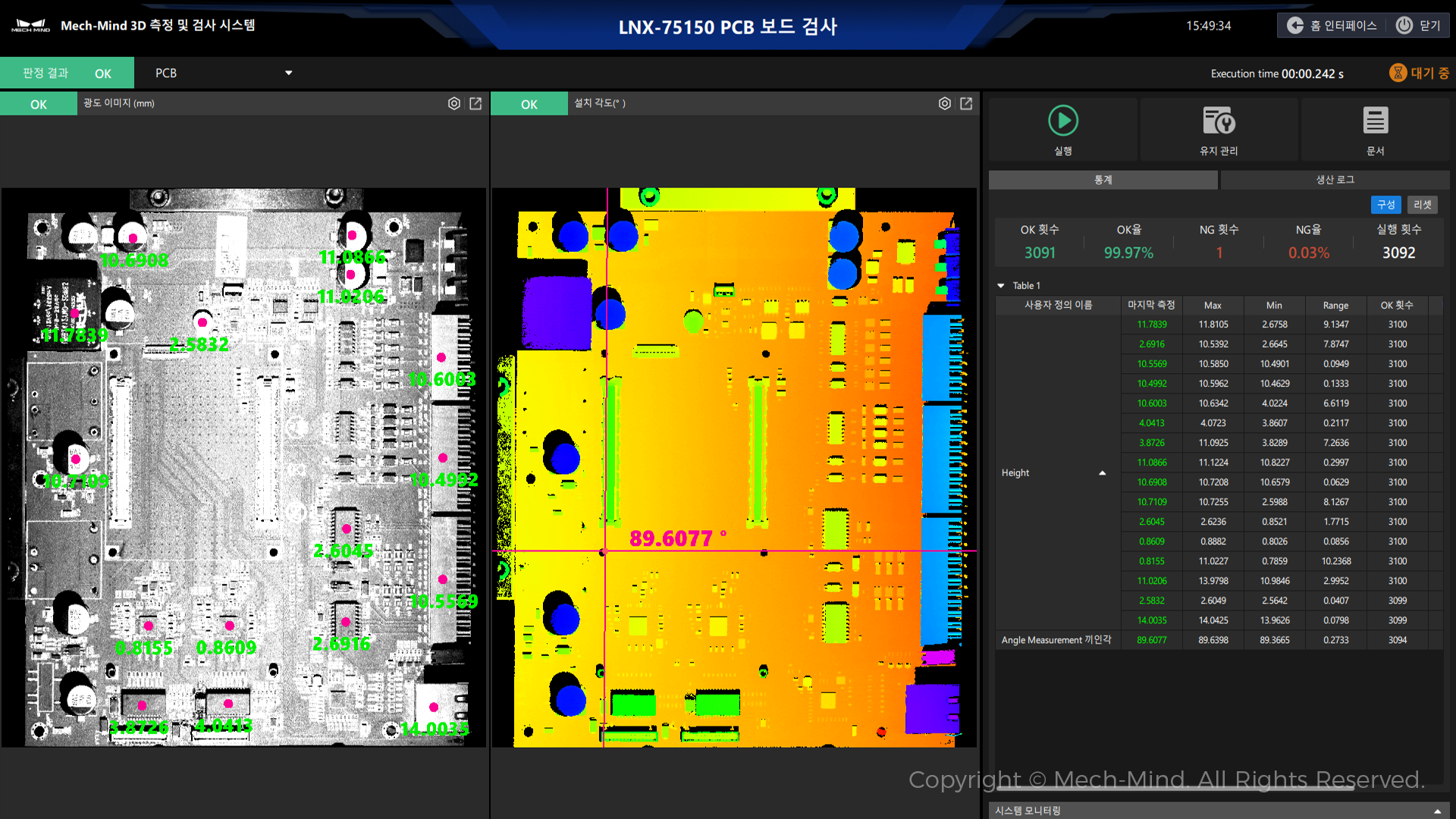

6. PCB Position and Height Measurement

PCB position and height measurement demo

Production interface

The Mech-Eye LNX-75150-GL 3D laser profiler quickly generates 3D point cloud data of PCB, enabling accurate height and position measurements. Its extended measurement ranges on the X and Z axes allow scanning multiple PCBs in a single shot. The single-shot HDR function ensures high-quality imaging of reflective and dark PCB components in one scan.

03 High-Performance and Versatile AI + 3D Products

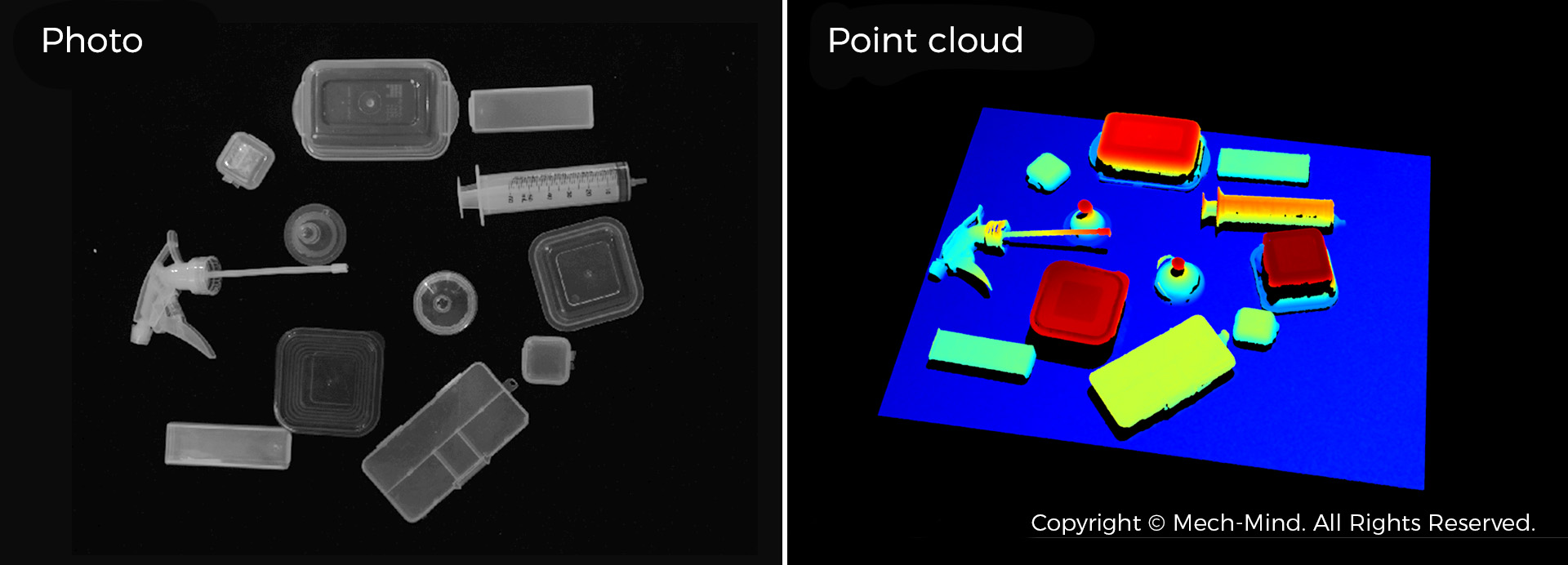

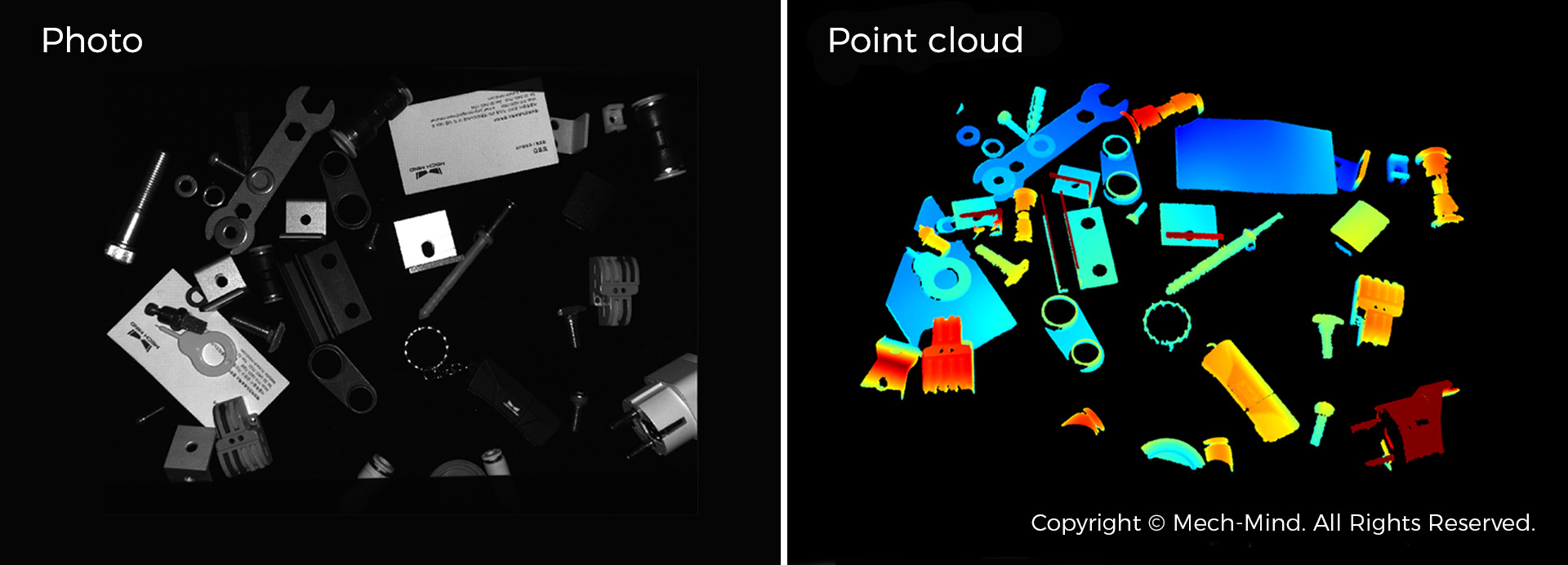

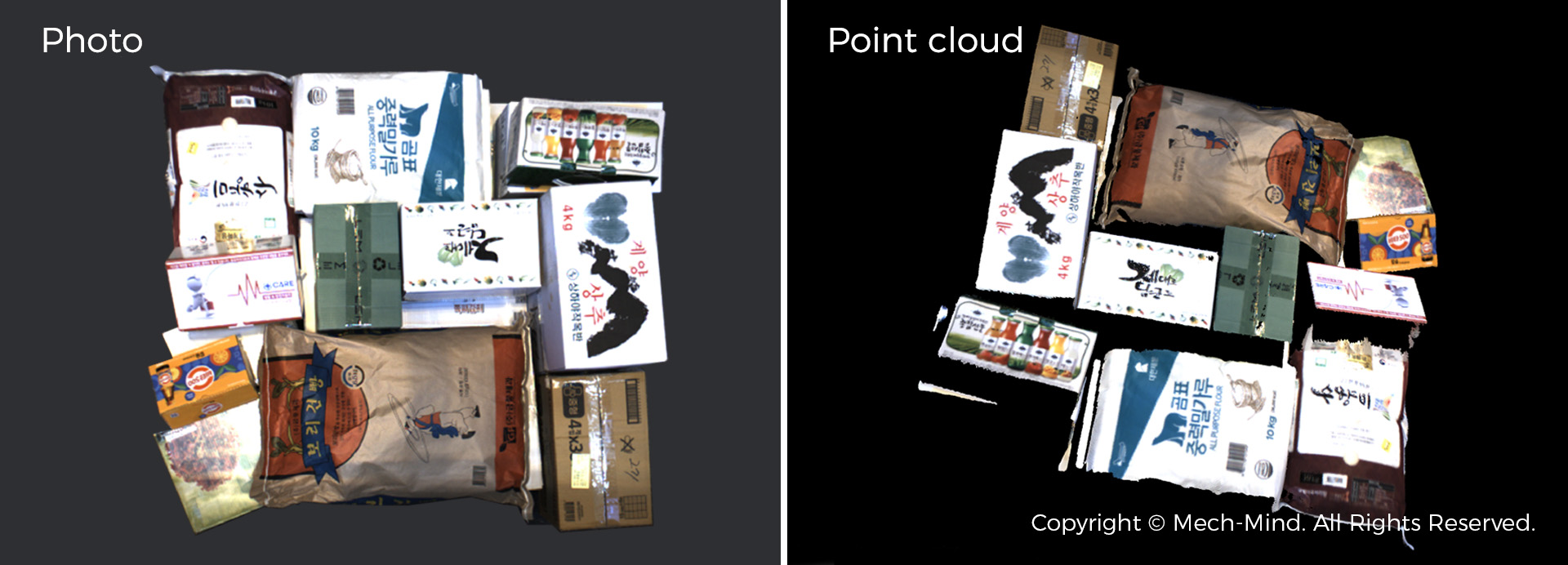

At the exhibition, Mech-Mind showcased the high-performance 3D vision sensors. Featuring excellent imaging capabilities, Mech-Eye industrial 3D cameras provide high-quality 3D imaging of various challenging objects, including multi-SKU cartons and sacks, transparent items, reflective small parts, etc.

Using self-developed imaging algorithms, Mech-Eye PRO S-GL can generate high-quality 3D point clouds of various transparent objects such as medical syringes, saline bags, and plastic containers.

Using Mech-Mind's self-developed anti-reflection imaging algorithm, Mech-Eye PRO S-GL can capture high-accuracy 3D point clouds for reflective small parts, significantly improving imaging quality and greatly enhancing point cloud precision.

Mech-Eye DEEP-GL can deliver high-quality imaging for complex-patterned cartons and sacks.

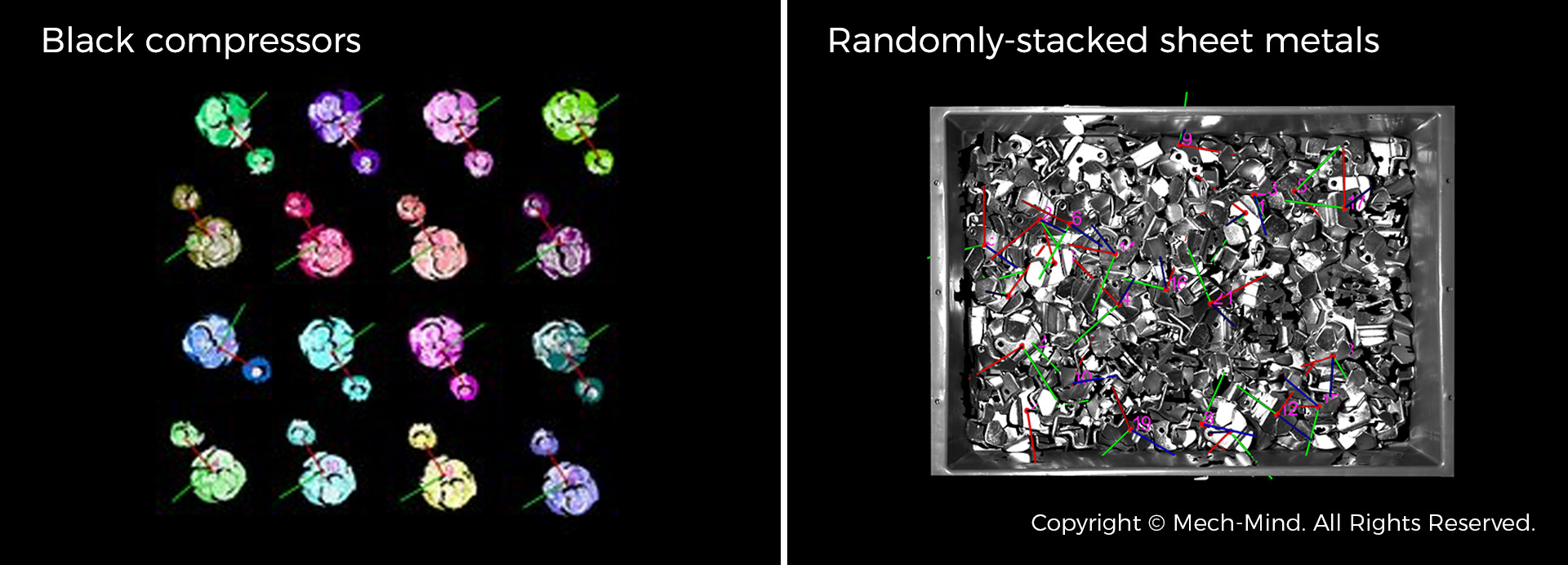

Mech-Mind also demonstrated the recognition ability of the AI + 3D vision products for disorderly-stacked reflective sheet metal parts and reflective black compressors. Equipped with upgraded software, the Mech-Eye industrial 3D cameras significantly improve point cloud accuracy for mirror-like reflective and black and reflective objects. Combined with advanced 3D vision algorithms, AI robots can accurately recognize various reflective objects in complex working conditions.

At this exhibition, Mech-Mind collaborated with several industry-leading partners to showcase multiple newly upgraded AI-powered robotic applications to the on-site audience.

Showcase units of Mech-Mind’s partners

Mech-Mind has established a branch in Seoul, Korea, to better support local customers with sales, technologies, and professional training. By providing advanced products and comprehensive services, the company assists partners in Korea and Asia-Pacific to implement more intelligent robotic applications in diverse manufacturing scenarios.

Mech-Mind has experienced rapid growth and gained strong customer recognition in multiple developed markets worldwide. Our products are available in over 50 countries and regions, with a global deployment exceeding 15,000 cameras, underscoring Mech-Mind’s extensive application experience and comprehensive technologies in the AI robotics field. Mech-Mind will adhere to productization, globalization, and ecosystem development, working together with global partners to accelerate the implementation of AI and 3D vision technologies.

For more information on Mech-Mind's products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net