Mech-Mind's

booth at Automate 2024

From May 6-9, the prestigious Automate

2024 took place at McCormick Place in Chicago, USA. As one of the largest and most professional robotics and

automation events in North America, Automate 2024 gathered more than 800 exhibitors from over 90 countries,

showcasing the latest advancements in cutting-edge robotics, vision, artificial intelligence, motion control and

related automation technologies across an expansive 365,000 square feet of exhibit space.

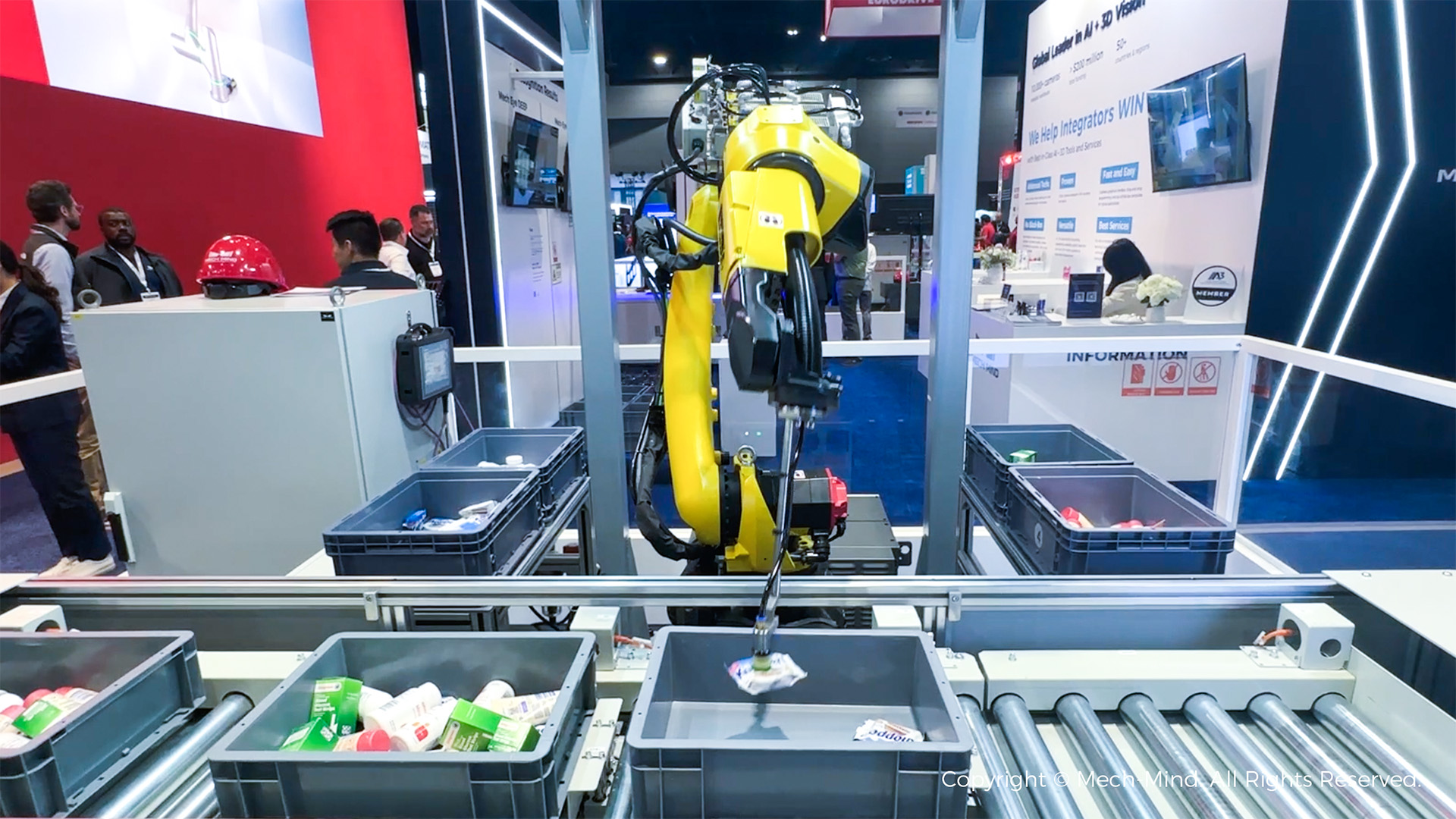

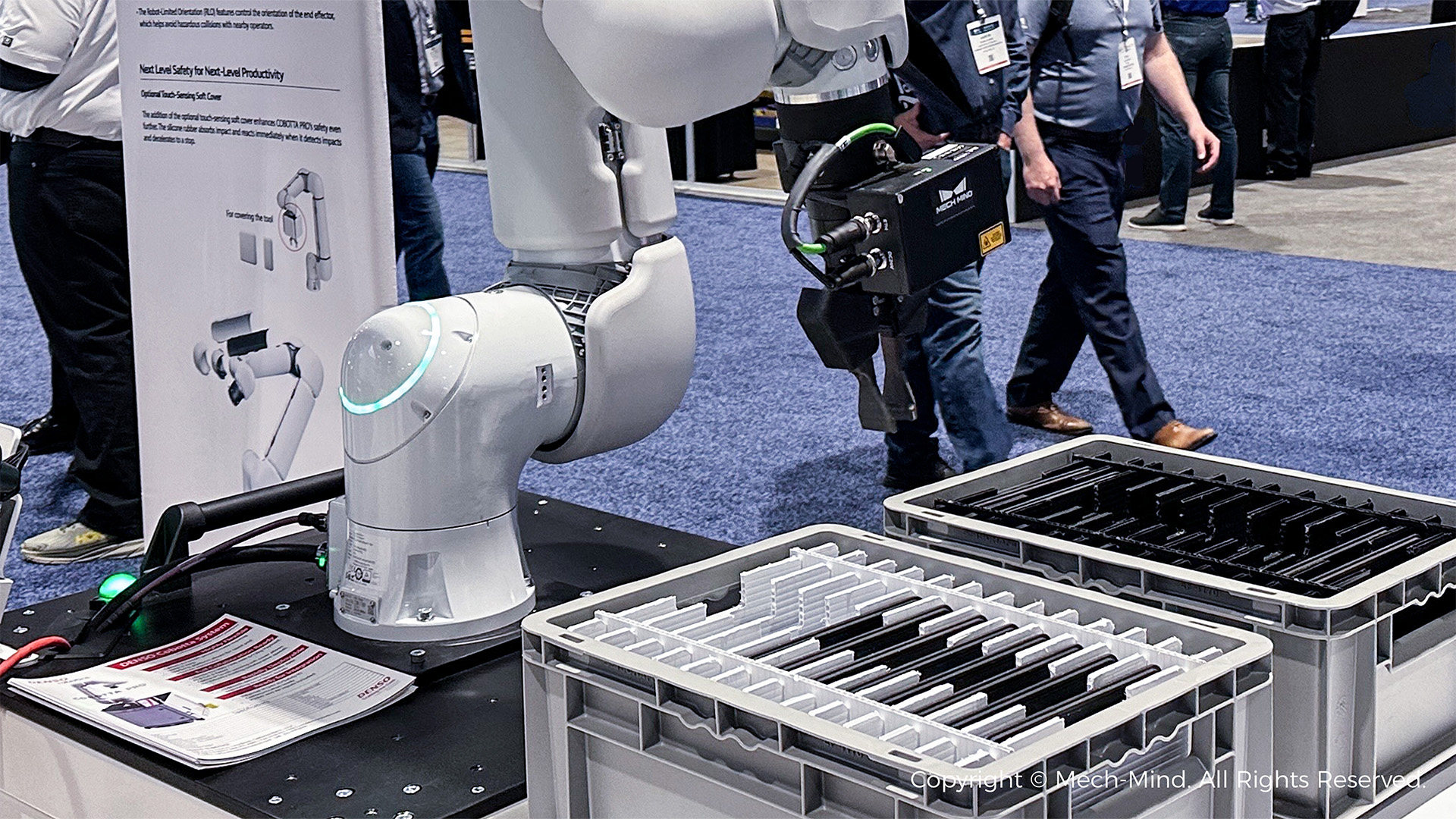

This marks Mech-Mind Robotics' second

appearance at this renowned automation trade show. As a global leader in AI and 3D vision, Mech-Mind exhibited

with a significant presence, boasting an exhibition area of nearly 200 square meters.

Collaborating with several partners,

Mech-Mind presented an array of over ten cutting-edge AI + 3D vision products and solutions. This drew a

substantial number of industry professionals and resulted in numerous inquiries from leading companies across

various industries.

01 Enhancing Product Quality Control with Advanced

Inline Inspection Solutions

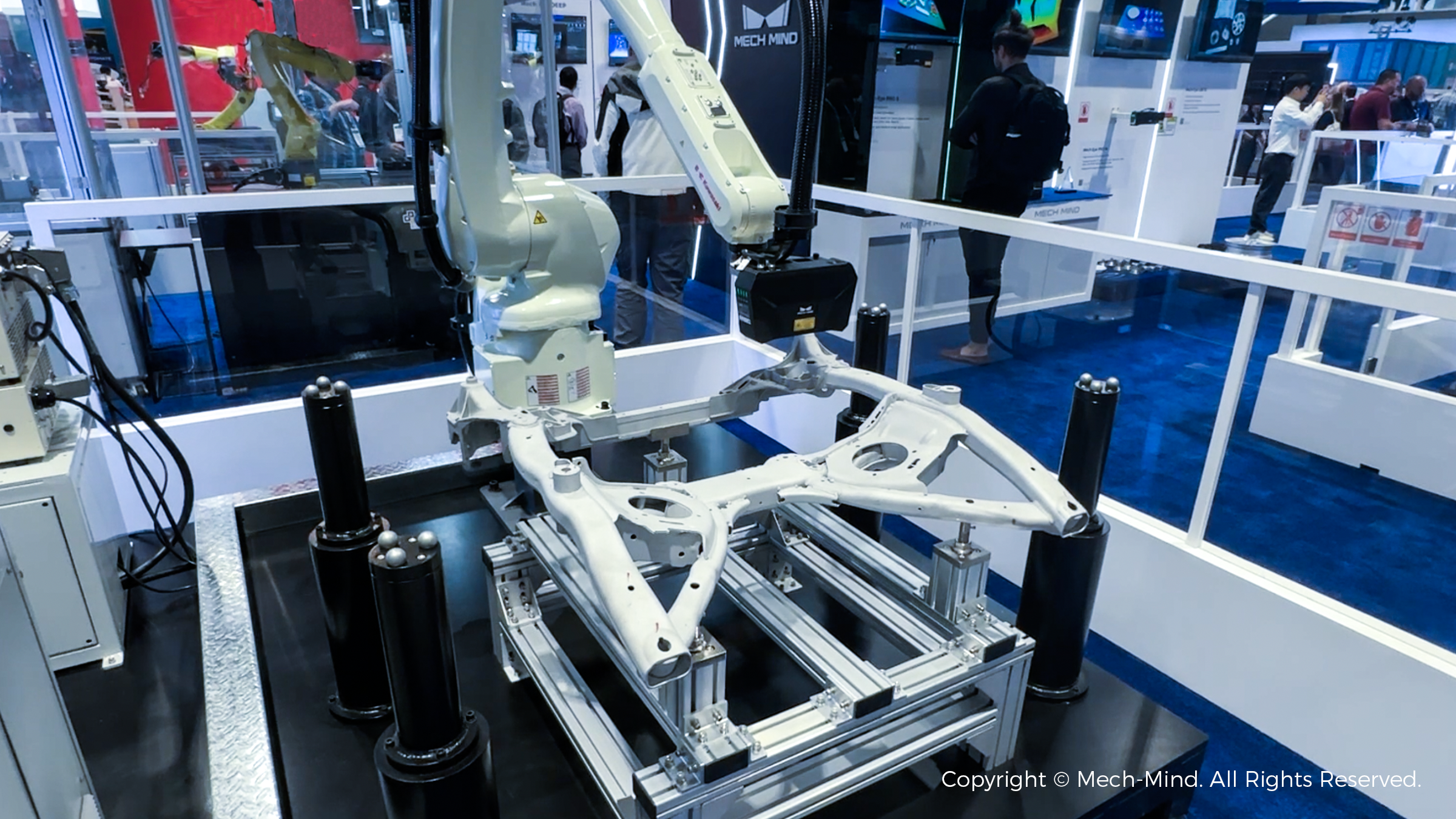

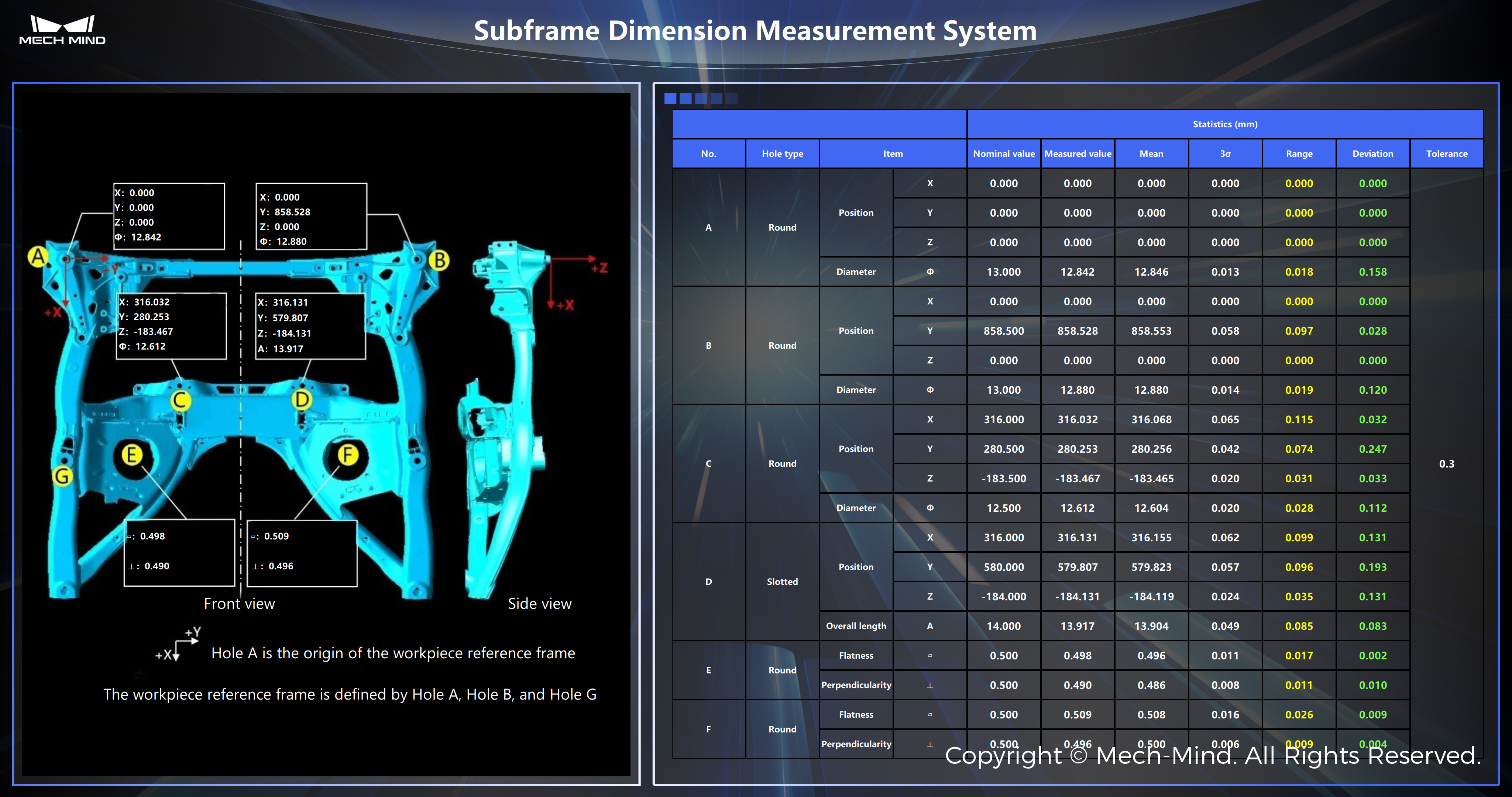

Subframe inline

measurement

100%

inspection, high flexibility, and high speed

Industrial robots equipped with the

micron-level precision Mech-Eye Industrial 3D Camera UHP-140 can perform non-contact flexible measurements of

subframes. The Mech-Eye UHP-140 adopts advanced imaging algorithms, easily dealing with the imaging interference

caused by irregular shapes, reflections, and blind spots. With its proprietary advanced measurement algorithms,

it achieves high-precision measurement of ±0.2mm for geometric dimensioning and tolerancing (GD&T) of key

features, with the fastest single-point measurement taking only 2 seconds.

Mech-Mind's inline measurement

solution has been deployed in numerous Tier-1 automotive manufacturers, helping customers achieve 100%

inspection and highly flexible, high-speed inline measurement. This ensures the delivery of projects to the

highest standards and with exceptional efficiency for our customers.

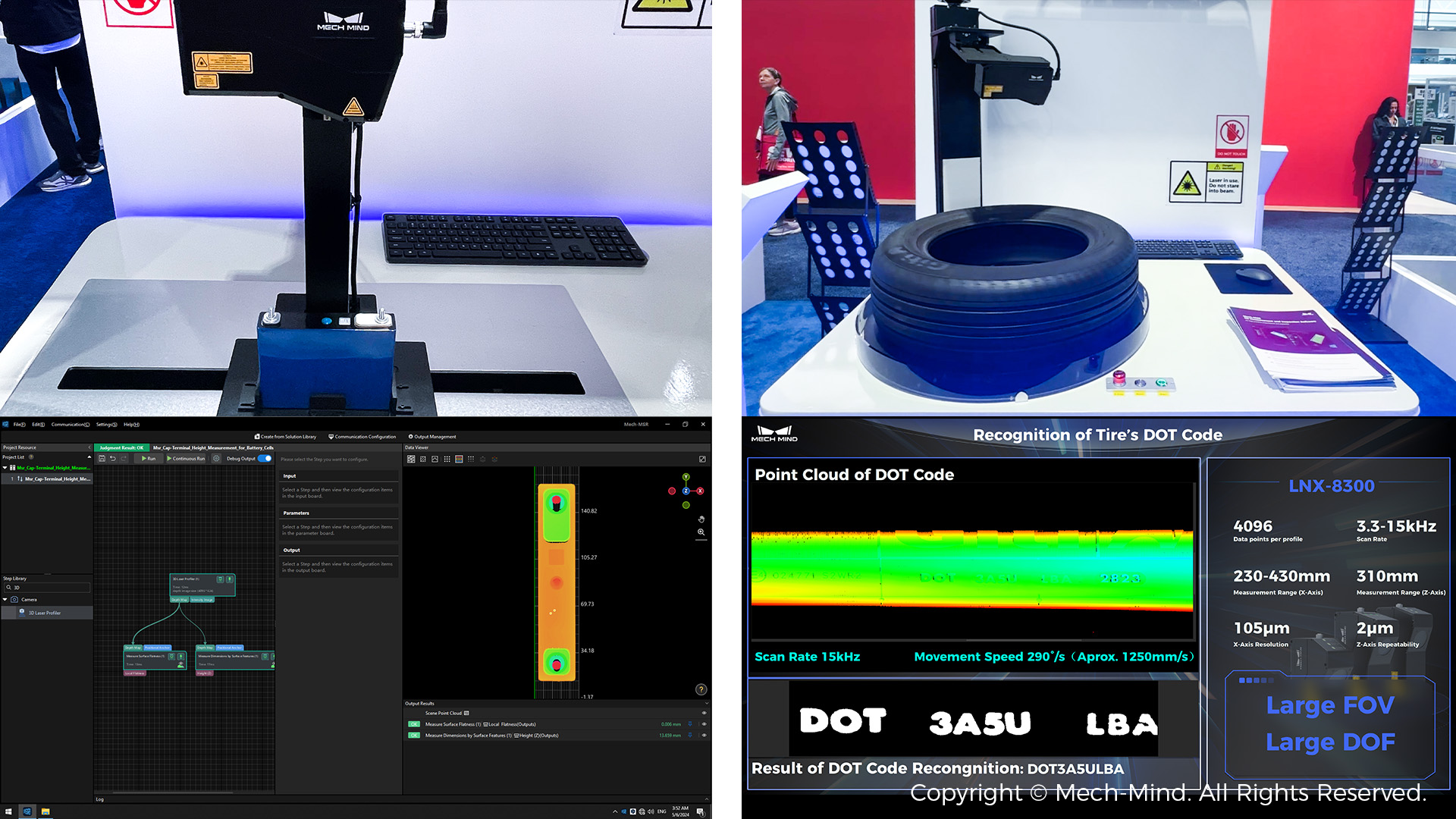

High-precision

inline quality inspection applications

Mech-Eye LNX +

Mech-MSR for the one-stop deployment of inspection applications

Mech-Mind displayed its capabilities in

flatness and height measurement of battery cell lid and tire DOT code reading, utilizing the brand-new

self-developed Mech-Eye LNX 3D laser profilers. Featuring ultra-high resolution and blazing fast scan rates, the

Mech-Eye LNX 3D laser profilers excel in measuring and inspecting various parts across industries such as PV, EV

battery, electronics, semiconductor, and automotive.

Mech-Mind's solutions are complemented

by the Mech-MSR 3D measurement and inspection software which offers a graphical, beginner-friendly user

interface. This enables users to rapidly deploy a variety of 3D measurement and inspection applications without

writing code.

02 Building Intelligent and Flexible Production Lines

through Mech-Mind's AI + 3D Vision Solutions

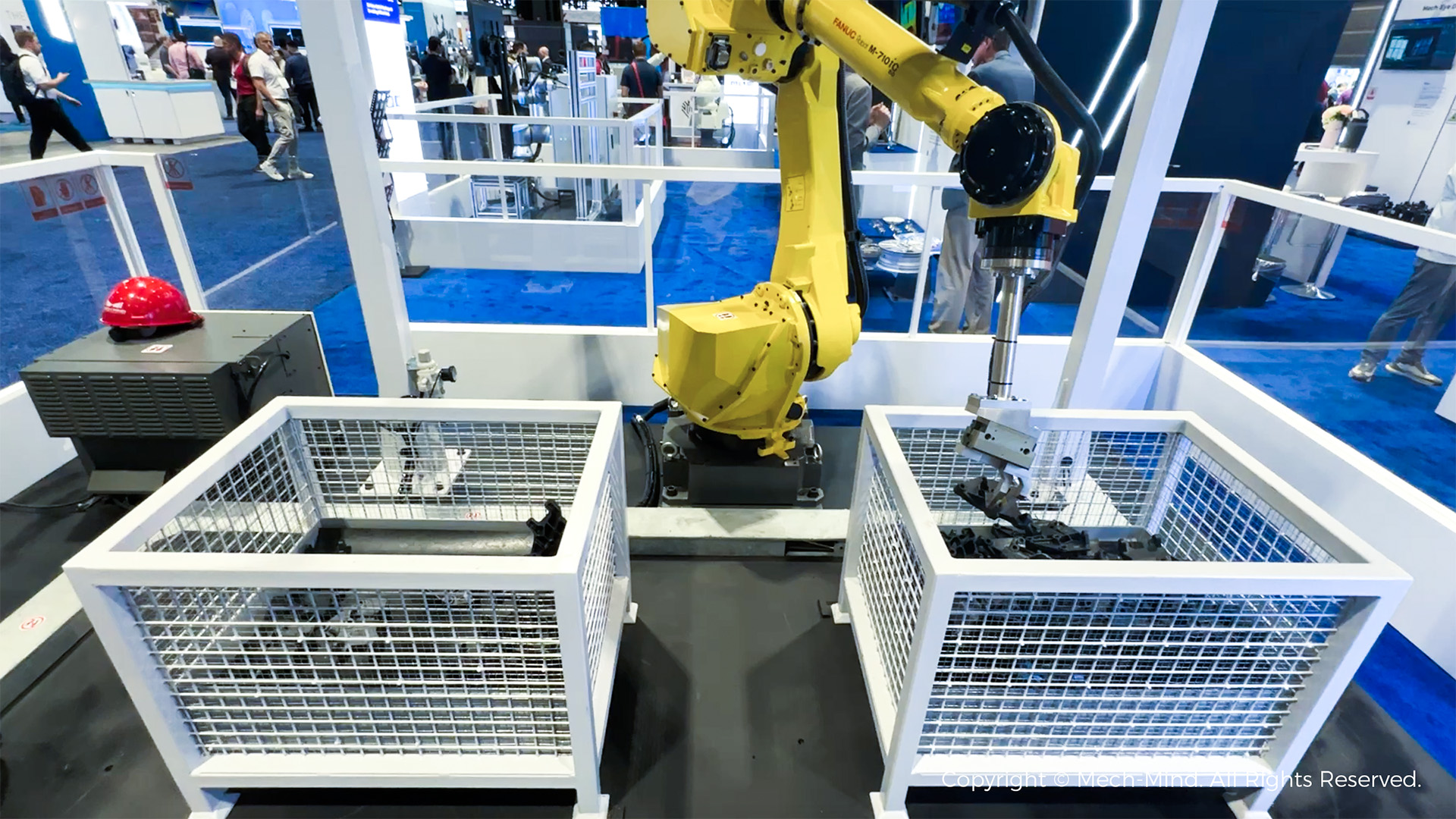

3D vision-guided bin picking of

irregular-shaped metal parts

Precise

recognition and picking in a complex scenario

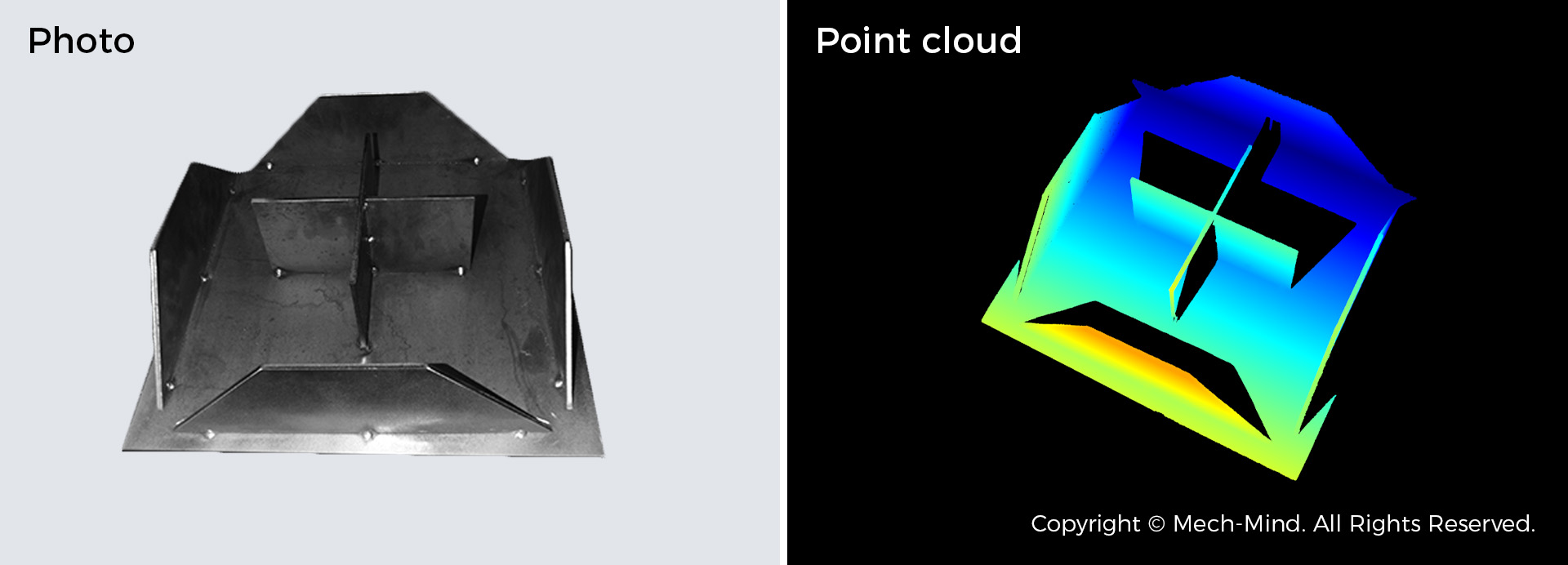

Leveraging the newly upgraded imaging

algorithms, Mech-Eye PRO M can generate more complete and detailed 3D point clouds for dark and reflective

irregular-shaped metal parts. The intelligent picking planning algorithm optimizes the picking angles and

sequences in real-time, making it easily tackle complex challenges such as parts positioned close to the bin

walls, stacked in the corners, and located in deep bins. This greatly improves the recognition rate and pick

success rate for complex parts on production lines for customers across automotive, steel, and other

industries.

3D vision-guided racking and

de-racking of sheet parts

Precise

recognition and placement of disordered, reflective, and ultra-thin sheet parts

The Mech-Eye NANO, featuring high-quality

imaging capabilities, captures complete details of reflective and ultra-thin sheet parts as fine as 2 mm thick.

Upon obtaining the parts' accurate 3D data, Mech-Vision calculates and generates the optimal picking pose

and sequence, adeptly mastering the variability in part orientation and stacking order.

In this application, the palm-sized 3D

camera adopts an arm-mounted installation, which is highly flexible and enables high-precision locating of each

hook to achieve precise placement.

3D vision-guided

depalletizing of shrink-wrapped beverage cans

Precise imaging

of reflective and transparent plastic packaging

Mech-Eye LSR L, leveraging the newly

upgraded imaging algorithms, can generate 3D point clouds with sharp edges and rich details for reflective and

transparent plastic packaging. Working in synergy with deep learning and 3D vision algorithms, it can also

accurately segment plastic packages, even when they are closely positioned with tiny gaps, and generate precise

pose information for accurate picking.

Piece

picking

Adapt to

changing inventory and new items without pre-registration

Mech-Mind excels in efficiently handling

millions of SKUs and adapting to new items seamlessly without previous registration. The advanced 3D vision

system is adept at recognizing and handling a wide range of items, including bottles, boxes, transparent and

dark objects, as well as objects of various sizes and complex patterns. This capability ensures that our system

meets and exceeds the cycle time demands of actual production needs.

Equipped with an intelligent stacking

detection algorithm, the system can accurately detect stacking conditions, preventing issues such as mis-picks

or dropping. This innovation leads to a more reliable and efficient picking process, setting a new standard for

e-commerce fulfillment and warehouse automation.

Random bin picking

of small rings and bolts

Fast and

accurate picking of reflective, small parts

Mech-Mind's 3D vision system

demonstrated remarkable competence in random bin picking of small parts, such as highly reflective, small, thin

rings and dark, reflective bolts. The system can efficiently navigate complex scenarios, including parts

randomly positioned, densely stacked in corners, or close to bin walls. With a cycle time as short as 1.9

seconds, the system meets the speed requirements of actual production lines and greatly boosts production

efficiency and accuracy.

03 Experiencing the Mech-Eye Industrial 3D Cameras

and Their Impressive Point Cloud Demonstrations

At the Automate show, Mech-Mind exhibited

a lineup of newly upgraded flagship industrial 3D cameras, including Mech-Eye PRO S, Mech-Eye PRO M, Mech-Eye

LSR XL, and Mech-Eye NANO ULTRA. These state-of-the-art 3D sensors captivated attendees with their exceptional

ability to produce high-quality point clouds for a wide range of challenging parts, such as transparent objects

and highly reflective parts.

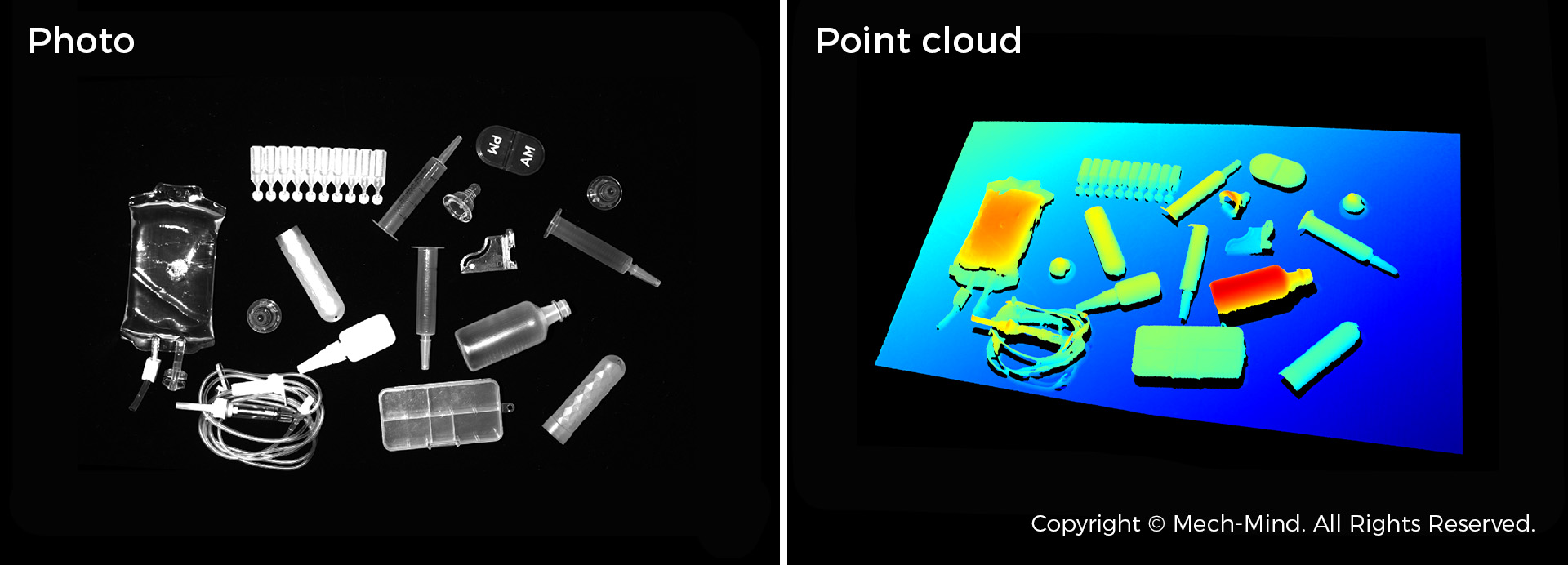

Transparent

objects

The newly upgraded Mech-Eye PRO S,

equipped with self-developed imaging algorithms, can generate high-quality 3D point clouds for various

transparent objects such as beverage bottles, medical test tubes, saline bags, and glass boxes.

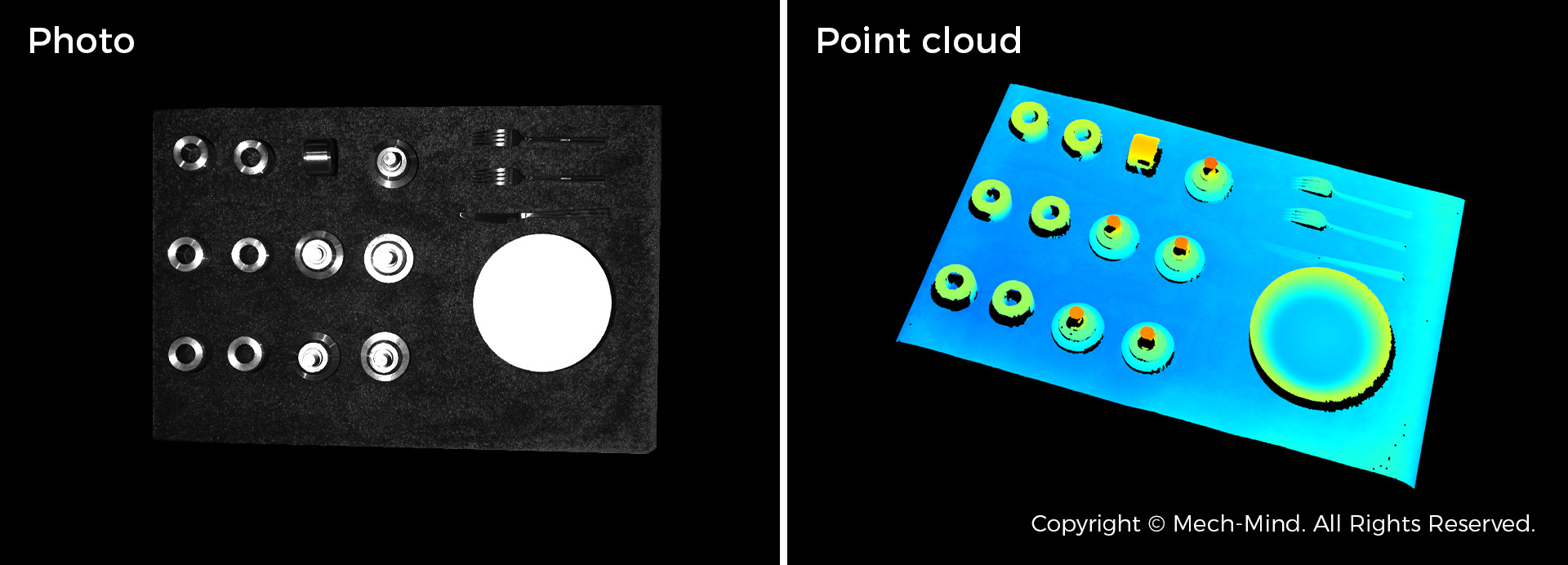

Reflective

parts

Mech-Eye PRO M offers a reflective mode,

which greatly enhances the imaging quality of reflective objects. This mode improves the accuracy of point

clouds by 90% compared to the previous modes.

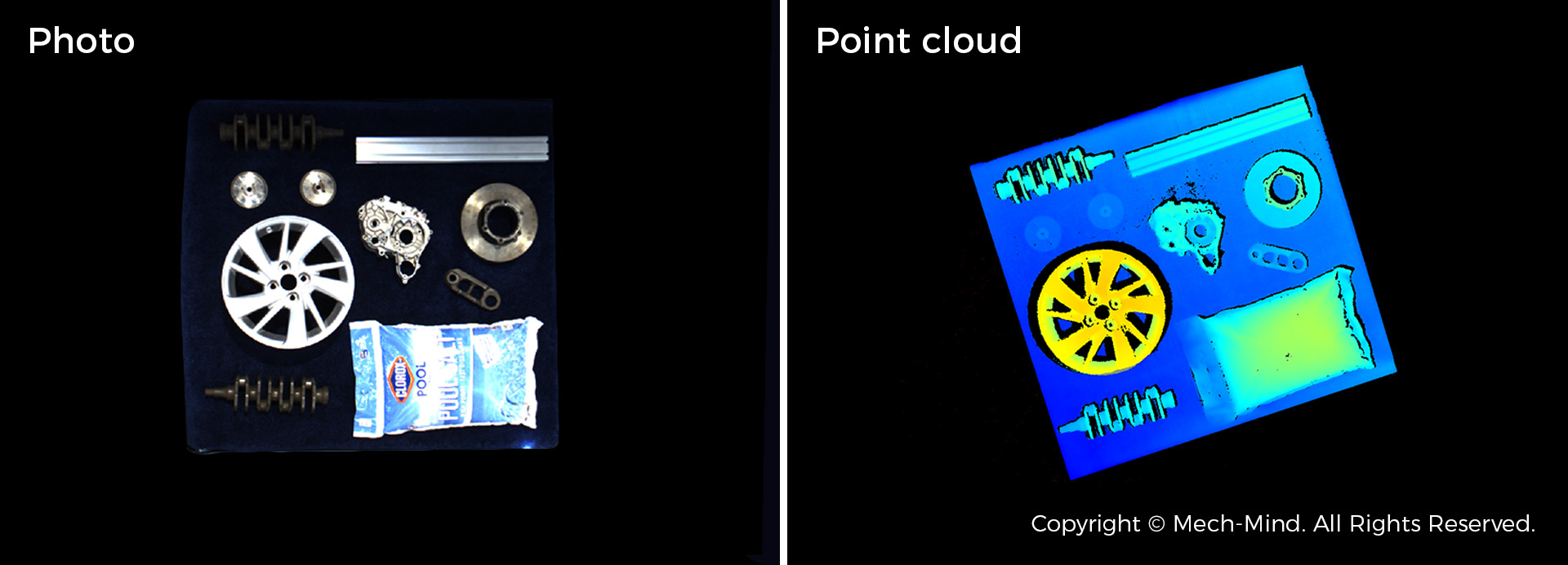

Collection of

challenging objects

Mech-Eye LSR XL, with its ultra-high

resolution and super-large scanning range, is capable of capturing complete and accurate 3D data at long working

distances.

Weldment

Mech-Eye NANO ULTRA features a palm-sized

design, ultra-high precision, and an extended field of view. It can be mounted on industrial and collaborative

robots' arms, making it ideal for applications such as autonomous welding and fine assembly.

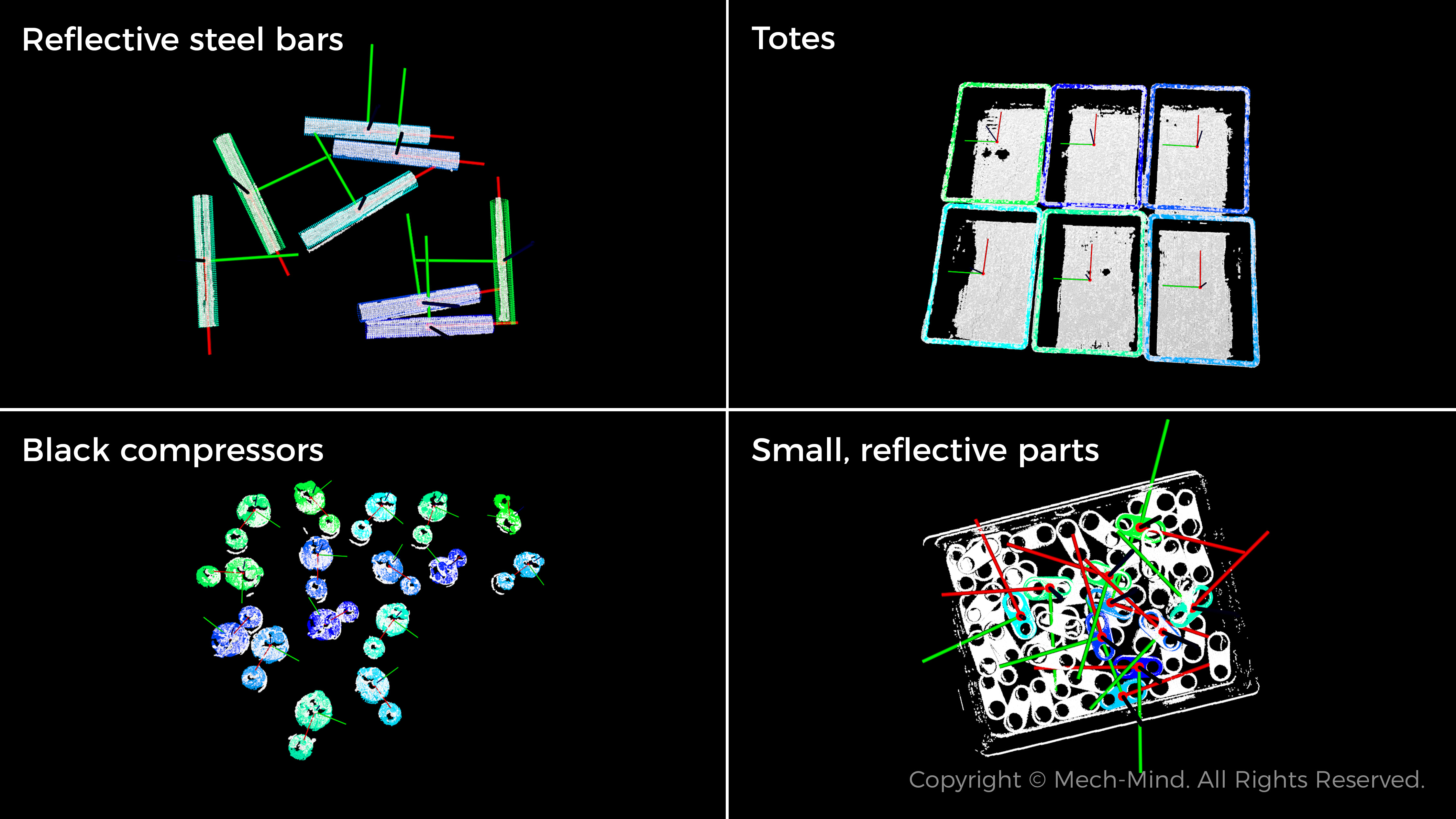

We also simulated real industrial

scenarios to show how our high-performance 3D vision products accurately recognize typical objects such as

tightly fitting totes, reflective steel bars, black compressors, and disorderly stacked small parts.

Mech-Vision, equipped with built-in advanced 3D vision algorithms, quickly recognizes the target objects and

generates accurate pose information after obtaining the point cloud data generated by the Mech-Eye 3D

cameras.

At the show, Vision Systems Design, a

leading global authority in machine vision, awarded Mech-Mind the prestigious 2024 Innovators Awards. This

accolade celebrates companies in the machine vision industry that have demonstrated excellence in products or

technologies, applications, or research and development. Mech-Vision, Mech-Mind's self-developed machine

vision software, was honored with the Bronze Award for its outstanding performance, marking the fifth award for

the company's products.

Mech-Vision, an all-in-one platform

software, manages all project steps from configuration to deployment in one system. This cutting-edge machine

vision software is designed to address even the toughest vision challenges. With a solution-oriented user

interface and integrated functional tools, users can realize easy setup and rapid application deployment.

At this exhibition, Mech-Mind joined hands

with several heavyweight collaborators to showcase a variety of newly upgraded intelligent robot applications to

the attendees.

Co-exhibition

demos

With a global presence, Mech-Mind has

established offices in Chicago, Munich, Tokyo, and Seoul to better serve its worldwide customers. The North

American office, located in Chicago, USA, provides comprehensive services spanning pre-sales, delivery, and

after-sales support, ensuring a consistent and stable supply of high-quality products and services to our

customers in North America.

Mech-Mind's products are used in more

than 50 countries and regions, achieving rapid growth and excellent customer approval in the global market. By

providing advanced products and comprehensive services, Mech-Mind is committed to assisting partners around the

world in realizing smarter robotics applications in a variety of manufacturing scenarios.

At Automate 2024, Mech-Mind demonstrated

its robust innovation capability and unlimited development potential. Mech-Mind will adhere to productization,

globalization, and ecosystem development, working together with global partners to accelerate the implementation

of AI and 3D vision technologies.

Looking ahead, Mech-Mind is committed to

continuous innovation and will release new products and software upgrades to provide more comprehensive and

detailed services to customers.

For more information on Mech-Mind's

products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR:

marketing@mech-mind.net