Mech-mind’s booth at Automate 2025

From May 12 to 15, Automate 2025 was held at Huntington Place in Detroit, Michigan, USA. As one of the world’s largest and most influential robotics and automation exhibitions, this year’s event spanned 36,000 m² and attracted 870 exhibitors from around the world. More than 40,000 professional visitors attended, setting a new attendance record.

As a global leader in AI + 3D Vision robotics, Mech-Mind made its third consecutive appearance at Automate. Through immersive, industry-specific displays, Mech-Mind showcased 10+ cutting-edge AI + 3D vision solutions across diverse industries including automotive manufacturing, smart logistics, and AI quality inspection, attracting numerous professionals to visit and exchange ideas.

Click to watch the video.

01 Self-Developed AI Algorithms Boost Logistics and Express Automation

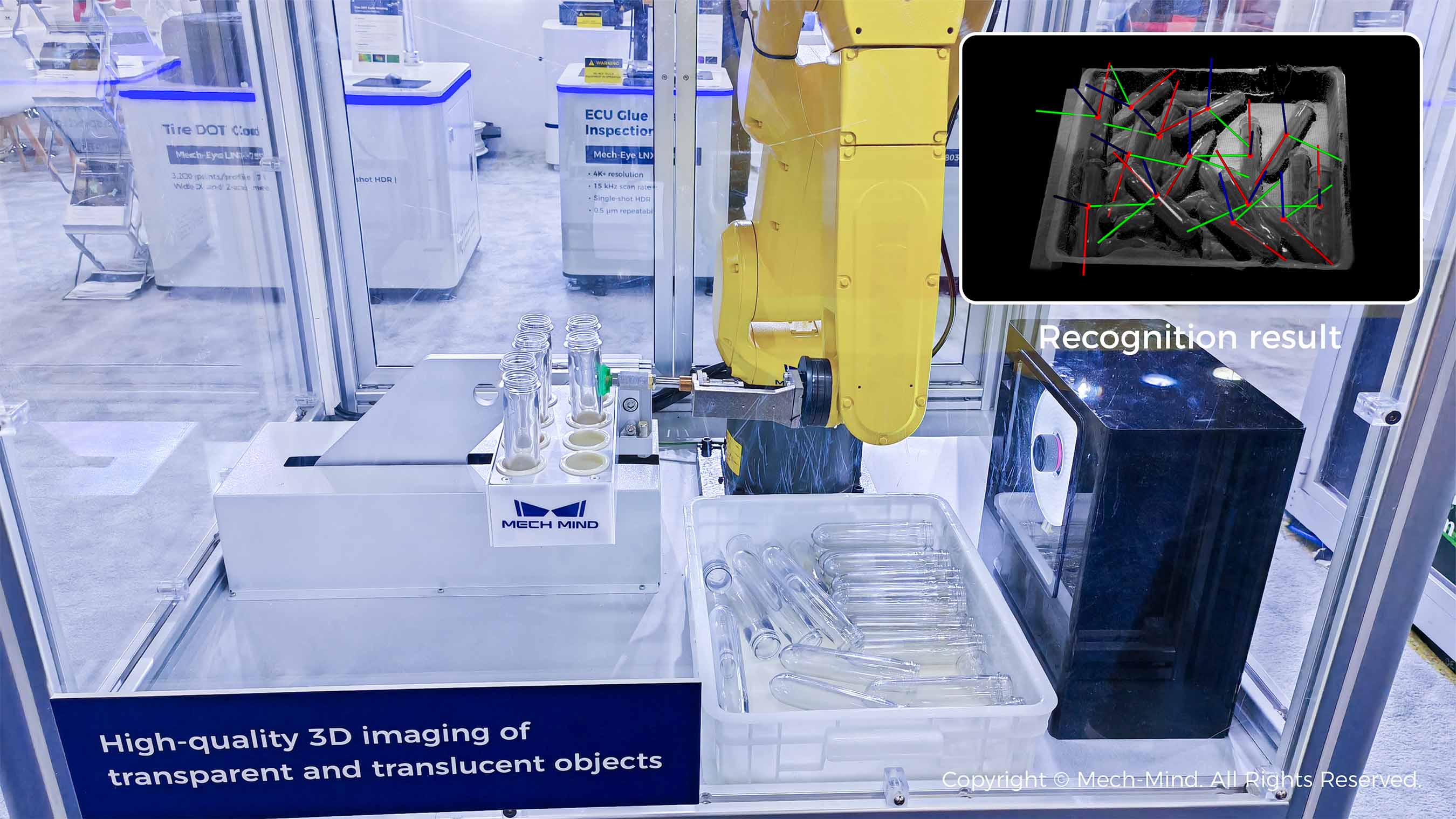

1. Random Picking of Transparent Test Tubes

Mech-Mind’s self-developed AI-based imaging algorithm for transparent objects enables highly accurate 3D imaging of transparent objects—even under challenging reflections and complex lighting conditions that make imaging difficult. The software uses these detailed point clouds to plan exactly how and in what order a robot should pick each tube. That means, even if tubes are randomly stacked, the robot can pick them precisely and reliably. The orientation recognition function ensures every tube is placed upright on its rack.

2. Depalletizing of Shrink-Wrapped Beverage Cans and Colored Cartons

From a 2.5 m distance, the Mech-Eye DEEP-GL camera captures full large pallet in a single shot, generating high-precision 3D point clouds of shrink-wrapped beverage cans and colored cartons. Even under complex interference caused by transparent wraps, reflective objects, colored patterns, or mixed SKUs, the camera reliably delivers high quality point clouds. Mech-Mind’s AI + 3D vision technology overcomes tight stacking and film deformation challenges, delivering reliable pick planning and motion trajectories that significantly enhance logistics speed and accuracy.

3. Registration-Free Parcel Induction

Optimized for express-parcel logistics, Mech-Eye PRO M-GL industrial 3D camera rapidly generates high-quality point clouds for foam boxes, poly bags, jiffy packs, envelopes, and more. The 3D vision system handles new parcels without prior registration, quickly adapting to changing packaging. The intelligent motion planning and overlap-detection algorithms can address challenges of randomly stacked and overlapped parcels. In real-world applications, the system processes up to 1,600 parcels per hour, meeting stringent sorting requirements.

02 Cutting-edge Structured Light Imaging Algorithm for Challenging Applications Across Industries

1. High-Precision Bin Picking of Sheet Metals

Mech-Mind’s Mech-Eye LSR XL-GL structured-light 3D camera combines an ultra-wide FOV and deep DOF to generate high-quality 3D point clouds of highly reflective, complex-shaped sheet metal parts in large pallets or deep bins. Advanced 3D vision algorithms locate each part’s key features and output accurate picking poses, while integrated AI algorithms for intelligent bin entry and exit, singularity avoidance, path planning and collision detection guide the robot to reliably pick the parts from deep bins.

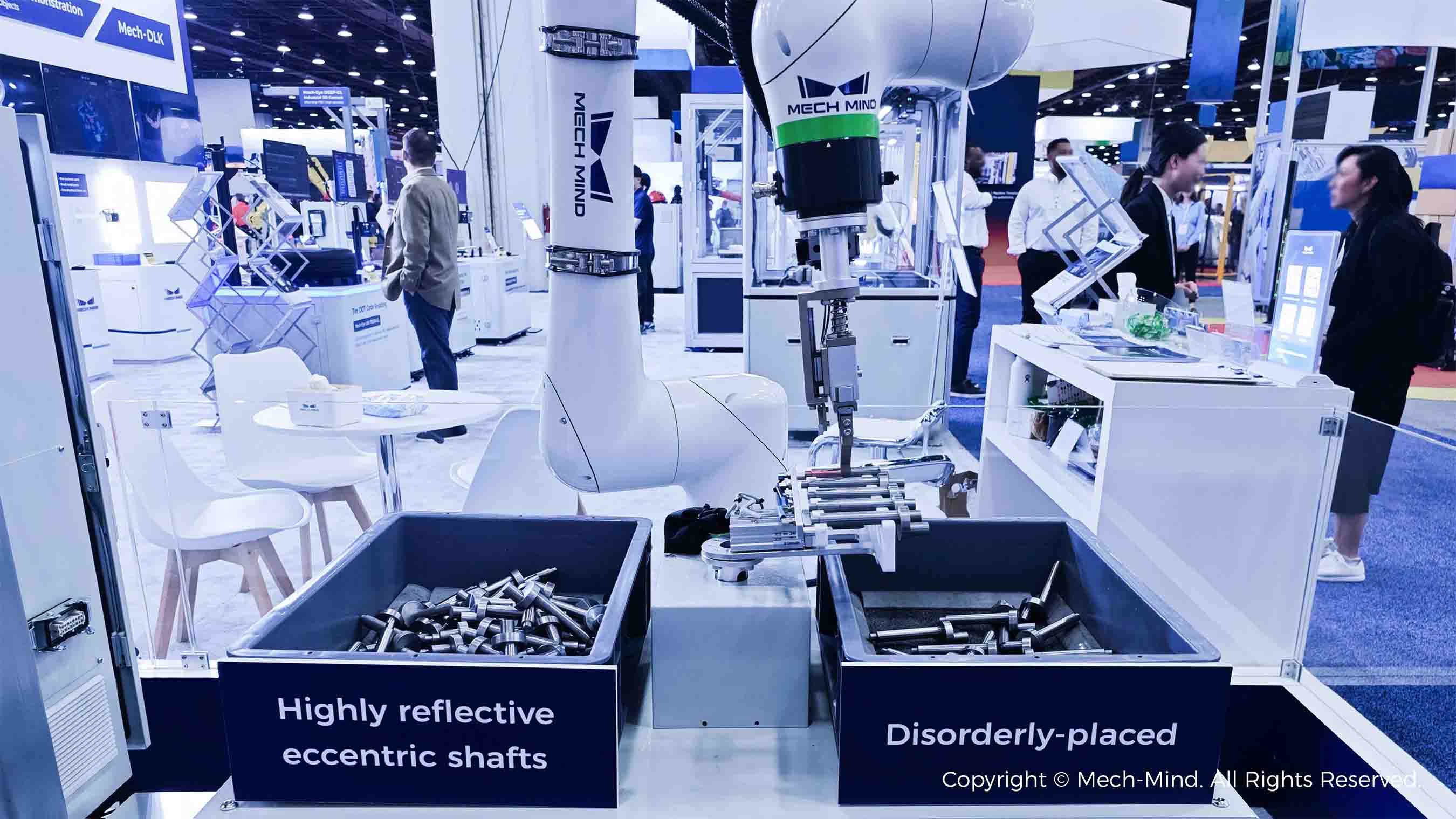

2. Bin Picking of Highly Reflective Eccentric Shafts

Leveraging our advanced structured light imaging algorithm, the Mech-Eye PRO S-GL captures complete stripe patterns on highly reflective eccentric shafts—despite bin-wall reflections. The sensor extracts precise contour features and generates high-resolution, low-noise point clouds, significantly enhancing recognition success rate and bin emptying rate in challenging scenarios.

3. High-Precision Assembly of Splines

Two Mech-Eye industrial 3D cameras, PRO S‑GL and NANO ULTRA‑GL, capture the highly reflective, structurally intricate external and internal splines, producing detailed 3D point clouds. The AI + 3D Vision system then guides the robot to pick randomly-placed external splines from the bin and align them with internal splines—achieving ultra-precise assembly.

4. High-Speed Picking of Small Rings

Mech-Mind’s AI + 3D vision robotics workstation processes highly reflective circular and square rings with thin outer diameters in mixed stacks, generating accurate picking poses for each target. Intelligent picking algorithms optimize both picking sequence and strategy, achieving a cycle time of less than 1.9 seconds to satisfy actual production demands for high-speed picking.

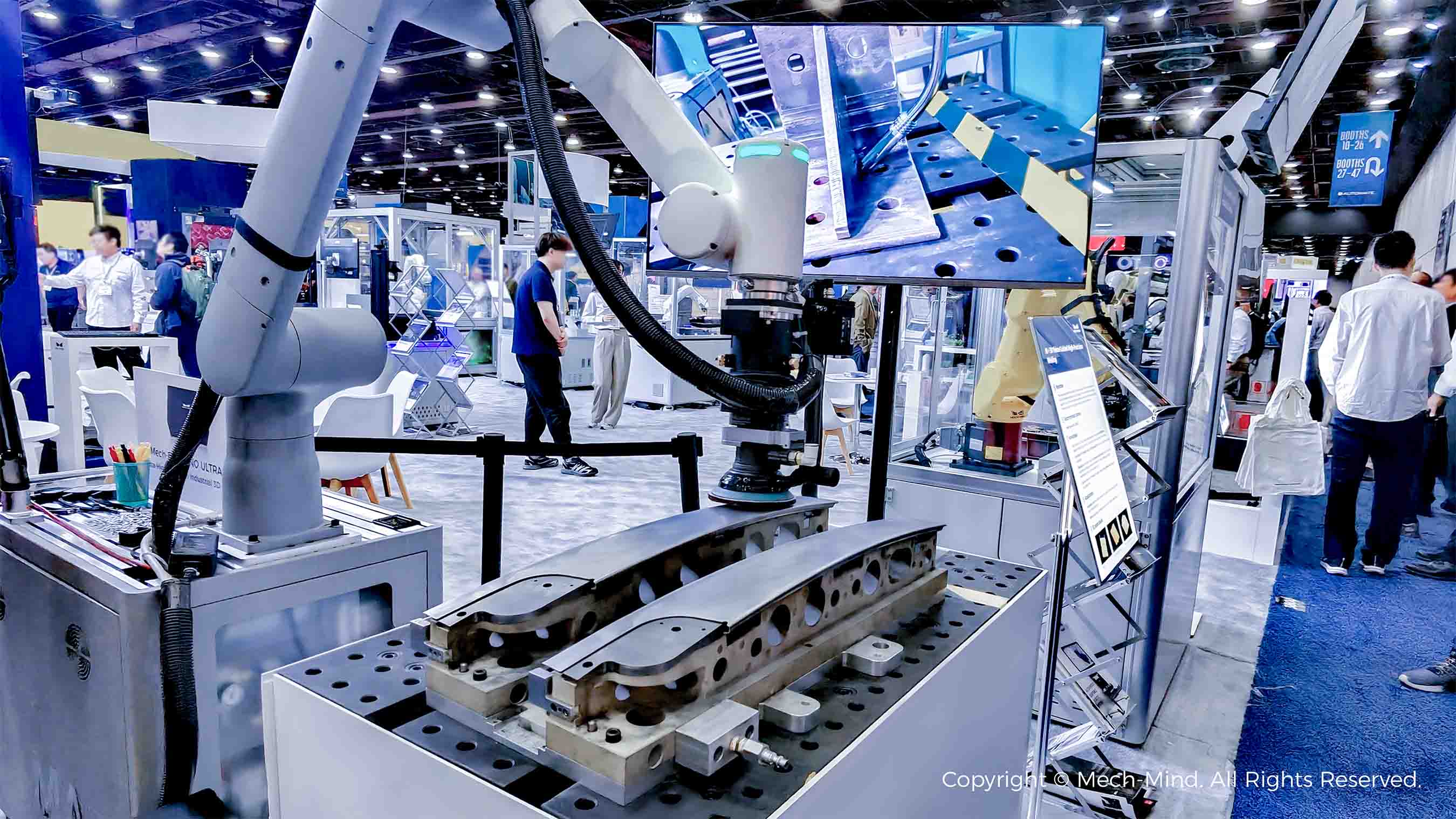

5. High-Precision Welding

High-precision welding demo

High-precision grinding demo

The Mech-Eye NANO ULTRA-GL industrial 3D camera delivers high-quality 3D imaging of weldments and weld seams—including highly reflective weldments and grooves, weld seams with interreflection, lap weld seams of thin plates. The camera can seamlessly connect to professional welding software through native API, allowing for efficient application deployment. The camera also supports automated grinding, enhancing overall line intelligence.

03 Hardware-Software Integration for One-Stop Deployment

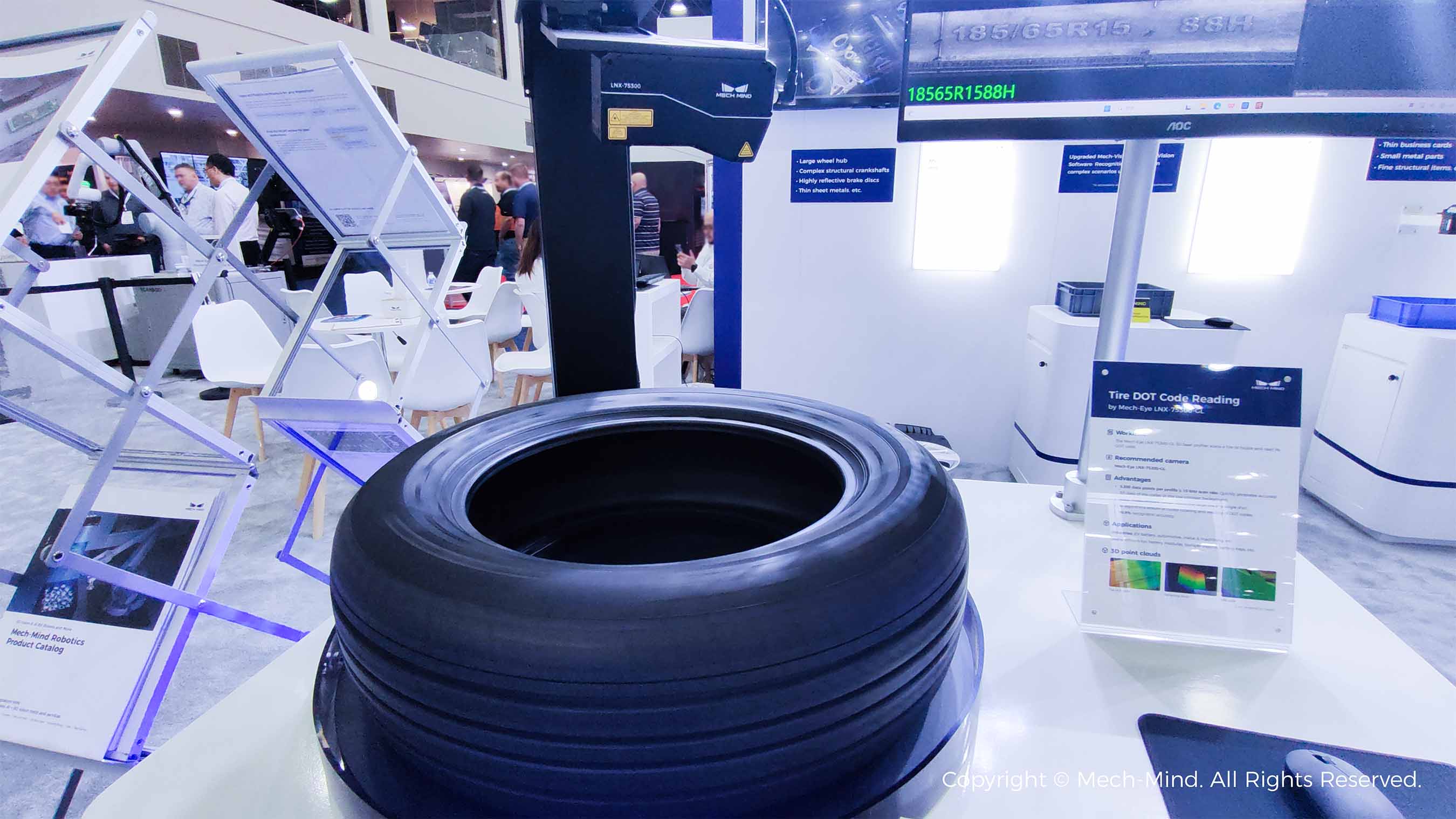

1. Tire DOT Code Reading

Tire DOT code reading demo

Production interface

The Mech-Eye LNX-8300-GL features 4K+ resolution, ultra-fast scan rate, and expanded X/Z measurement range, achieving high-quality 3D imaging of the large, light-absorbing, intricately textured tires. Our Mech-DLK deep learning software has built-in advanced character recognition algorithm. In complex situations such as complex characters and background interference, the recognition accuracy can exceed 99.9%.

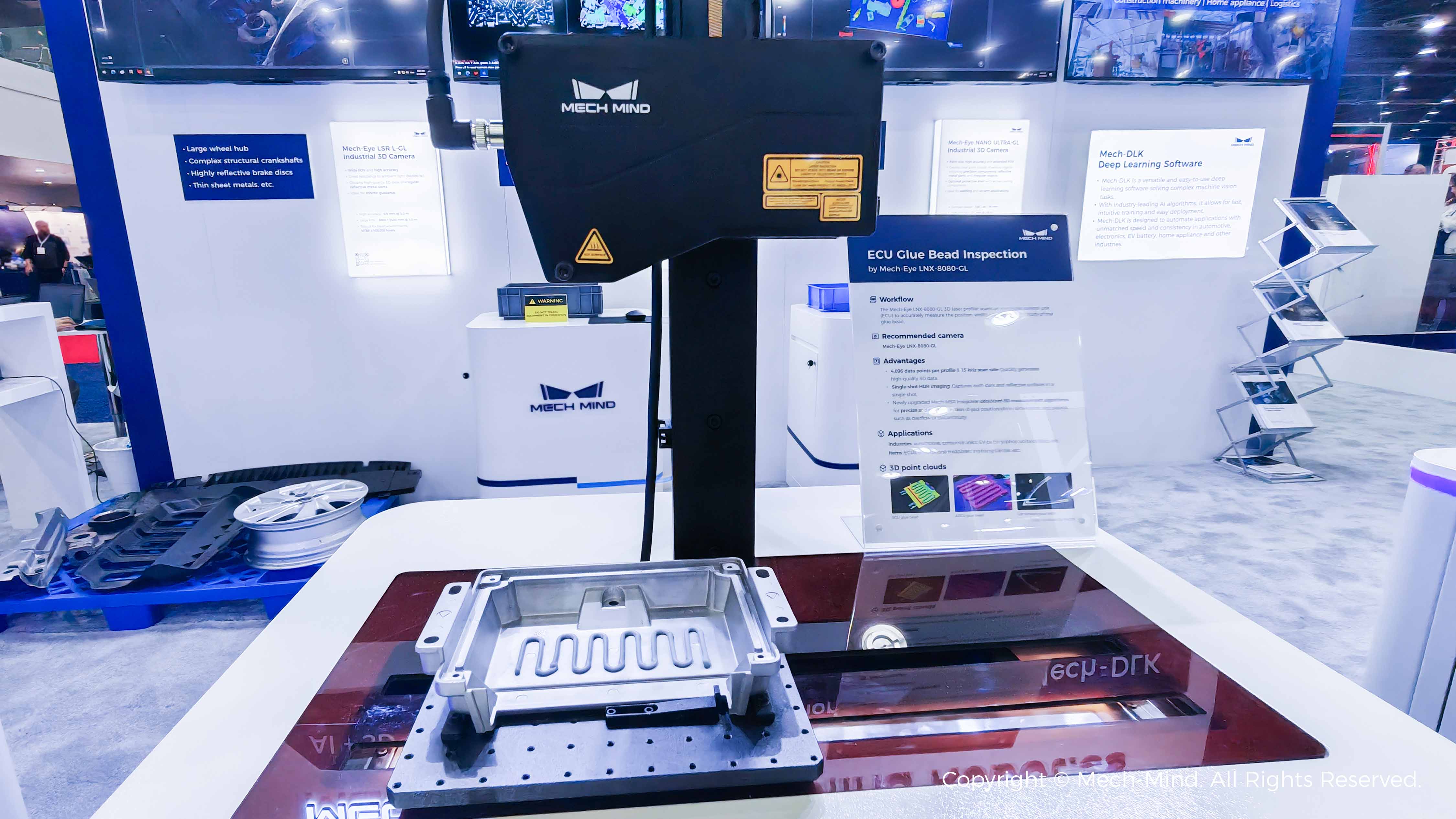

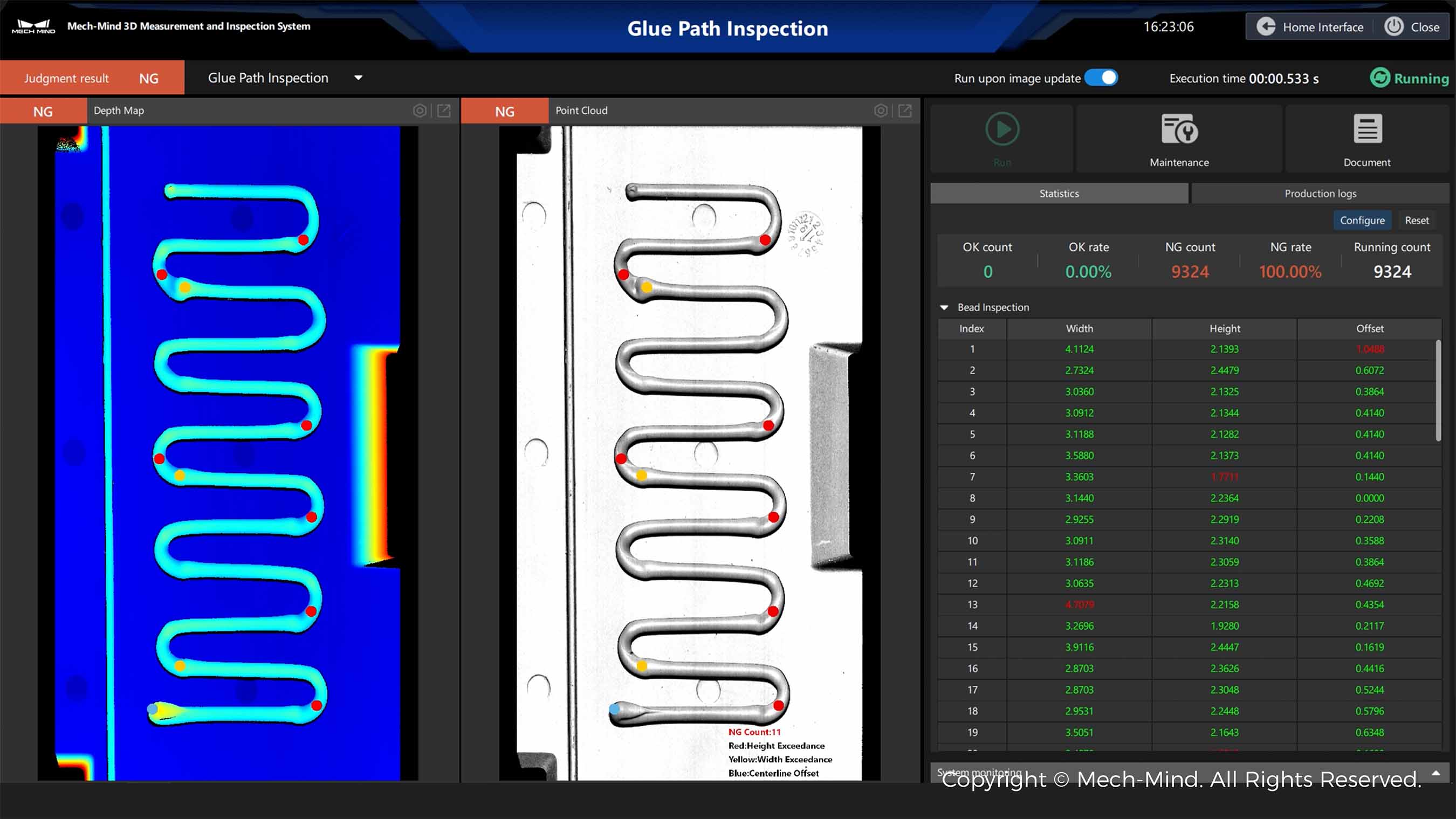

2. ECU Glue Bead Inspection

ECU glue bead inspection demo

Production interface

Innovative optical design and imaging algorithms enable high-quality imaging of glue paths with complex trajectories. The newly upgraded Mech-MSR integrates advanced 3D measurement algorithms for precise and rapid detection of glue bead position, dimensions, and defects such as overflow or discontinuity.

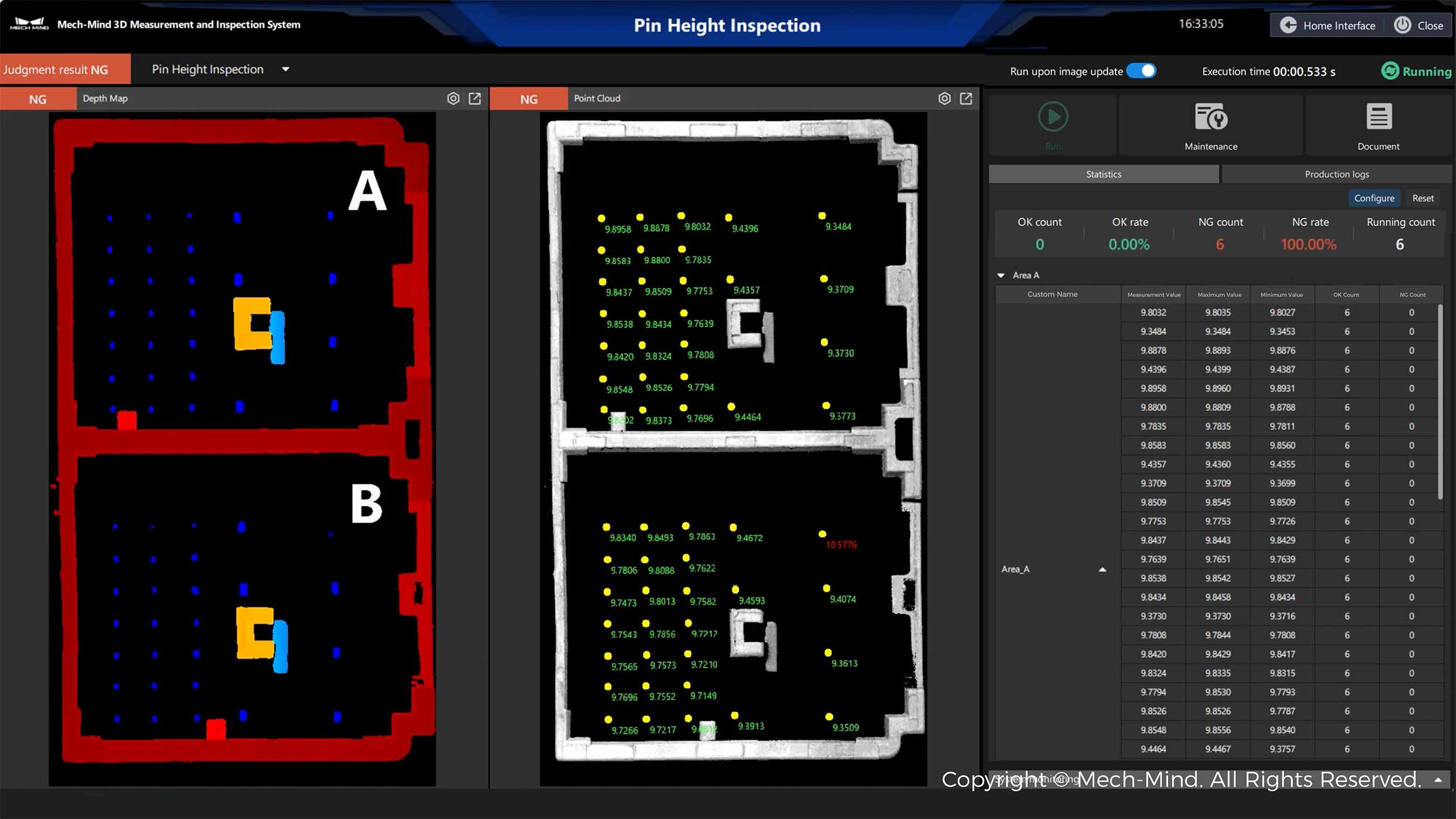

3. Connector Pin Inspection

Connector pin inspection demo

Production interface

The Mech-Eye LNX-8030-GL, with its 4K+ resolution, is capable of generating detailed point clouds of precision-structured and reflective pin tips. The Mech-MSR 3D Measurement and Inspection Software, integrated with advanced feature extraction and measurement algorithms, accurately measures pin height and position.

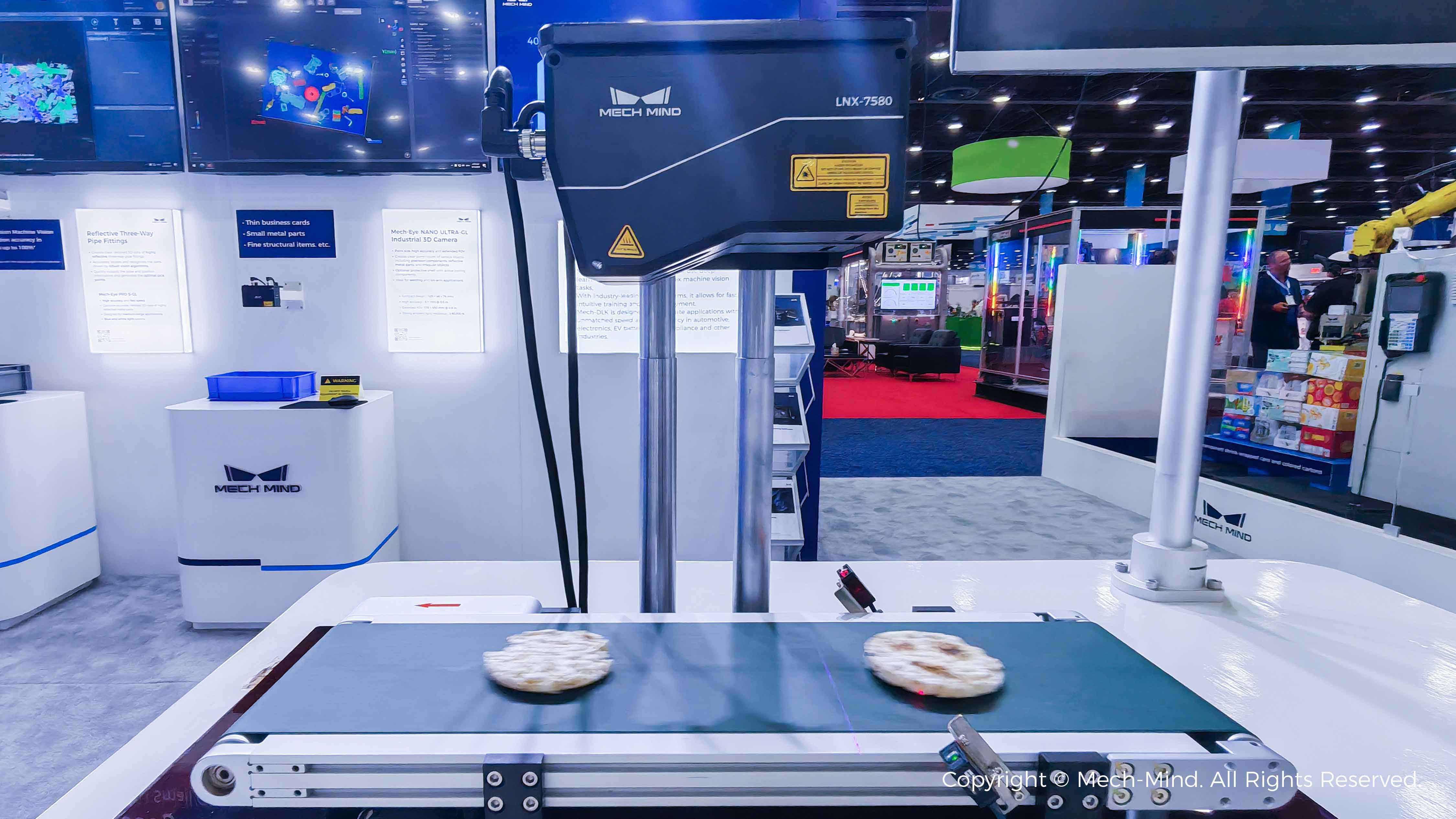

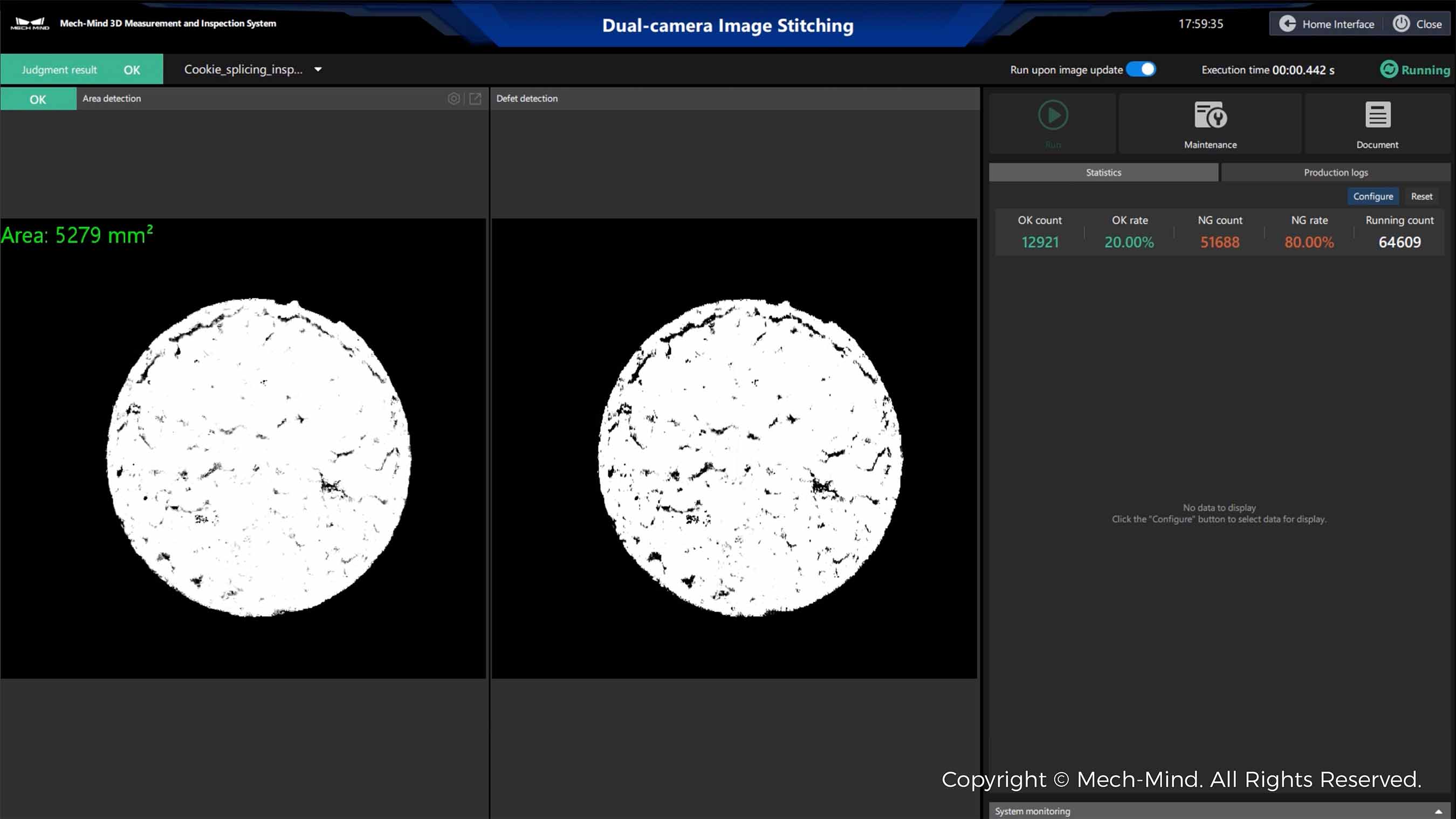

4. Rice Cake Inspection

Rice cake inspection demo

Production interface

Two Mech-Eye LNX-7580-GL laser profilers configured in a side-by-side setup perform inline scanning of rice cakes on the conveyor belt, inspecting whether the surface area of each target is up to standard and whether its surface is burnt. Leveraging high-quality 3D imaging and advanced measurement algorithms, the system enables accurate evaluation of object shape, dimensions, and defects.

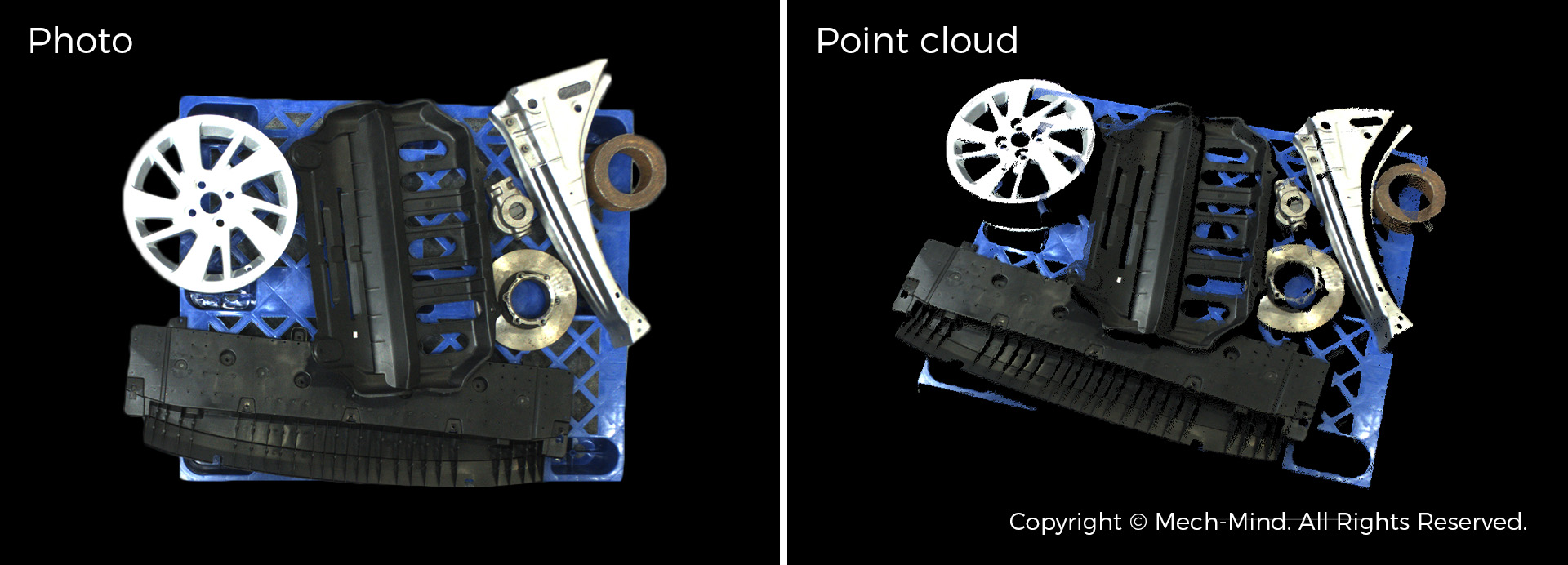

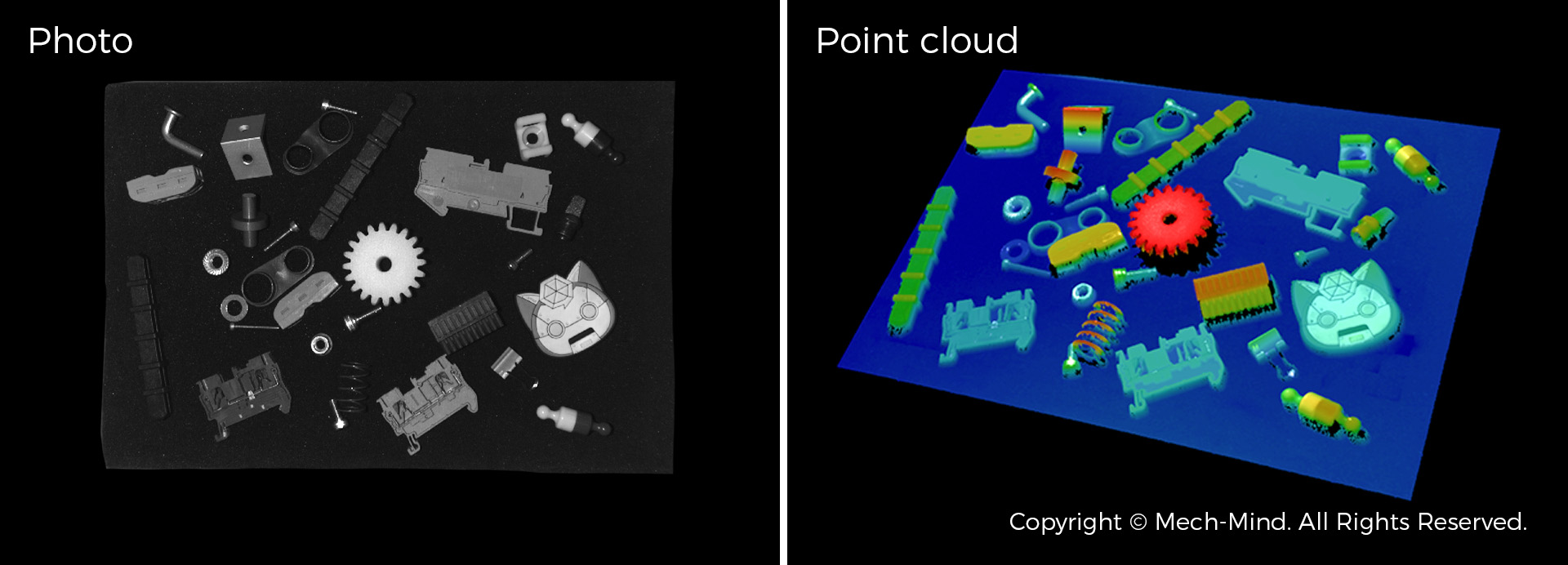

At the exhibition, Mech-Mind showcased multiple high-performance 3D vision sensors. Featuring excellent imaging capabilities, Mech-Eye industrial 3D cameras provide high-quality 3D imaging and recognition results of various challenging objects, including highly-reflective, dark, and precision-structured objects.

The Mech-Eye LSR L-GL generates high-quality point cloud of both dark and reflective part surfaces of the parts, even at a working distance of 3 meters.

The Mech-Eye NANO ULTRA-GL generates detailed point-cloud of small, reflective, and structurally intricate objects.

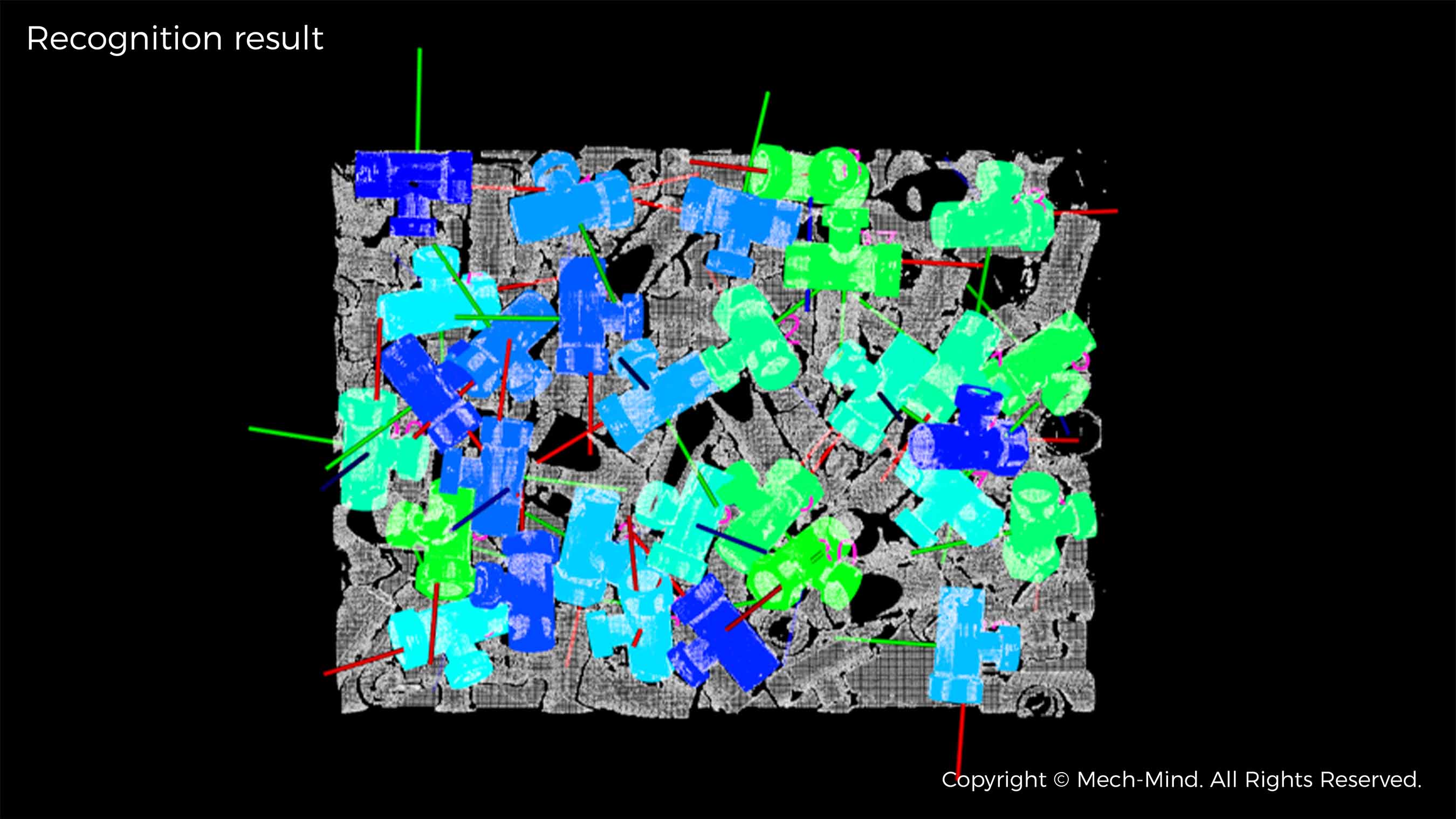

Recognition result of randomly stacked three-way pipe fittings

Mech-Mind has established the North American subsidiary in Chicago to provide comprehensive services spanning pre-sales, sales delivery, and after-sales support, ensuring a consistent and stable supply of high-quality products and services to our customers in North America. We’ve also launched branches in Munich, Tokyo, and Seoul to better serve our international clients.

With over 15,000 cameras installed worldwide, Mech-Mind has deployed applications in 50 countries and regions across various industries, including automotive, metal & machining, logistics, EV battery, electronics, and more. Mech-Mind has earned trust and recognition from global clients and integrators, solidifying its position as a global leader in AI + 3D vision robotics. By advancing its core strategies of productization, globalization, and ecosystem development, Mech-Mind continuously dismantles barriers to AI adoption—empowering worldwide partners to achieve seamless intelligent transformation at scale.

For more information on Mech-Mind's products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net