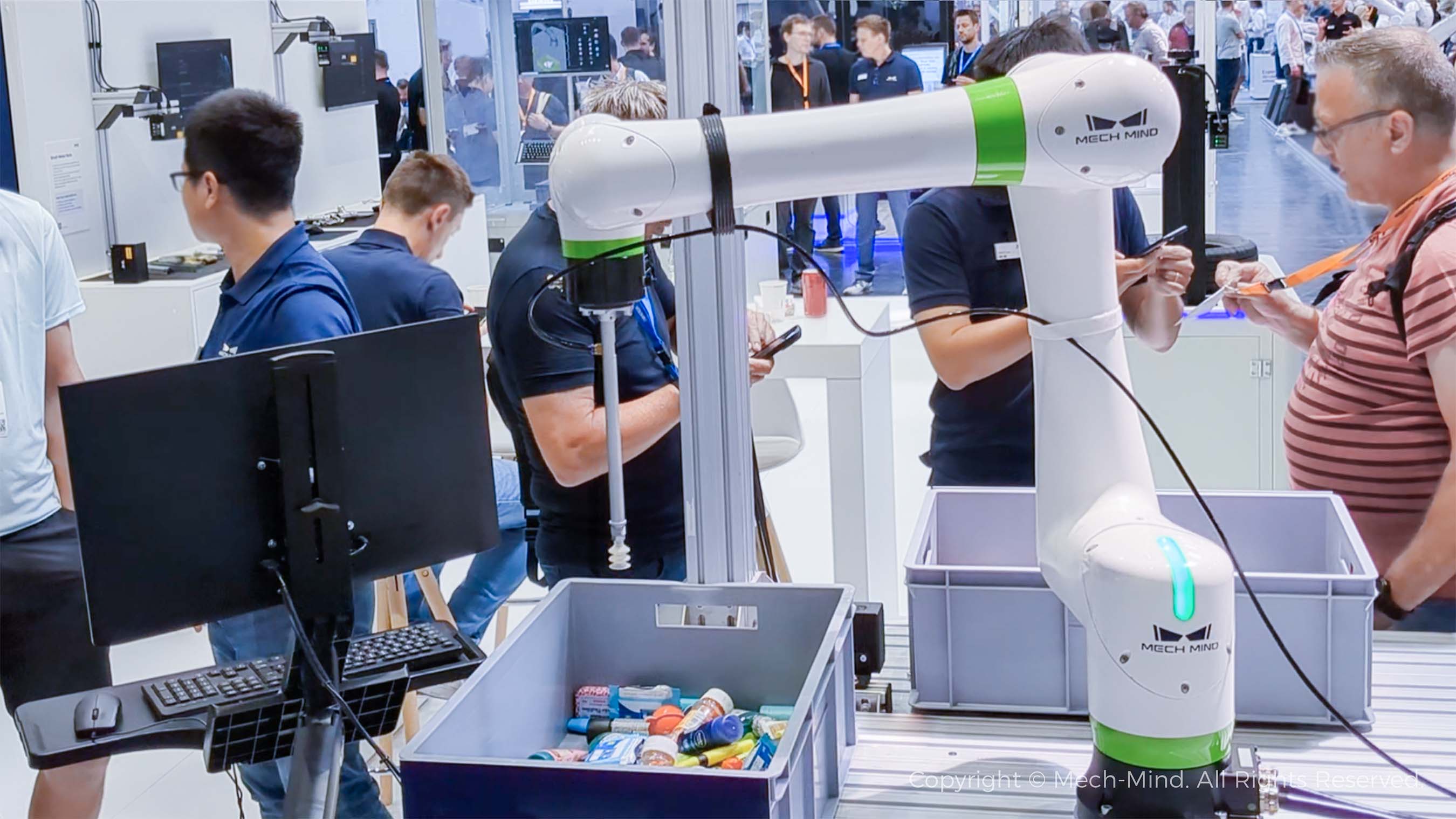

Mech-Mind’s booth at automatica 2025

From June 24 to 27, automatica 2025 was held at the Trade Fair Center Messe München in Munich, Germany. As the world’s leading trade fair for smart automation and robotics, automatica 2025 expanded further in scale and internationalization, covering over 70,000 m² and attracting nearly 900 of the world’s leading companies, 45,000 industry experts and professional attendees.

As a global leader in AI + 3D vision robotics, Mech-Mind made its third consecutive appearance at automatica. At the booth, it showcased industry-leading AI + 3D vision technologies including registration-free high-speed piece picking, ultra-long working-distance imaging, etc., and demonstrated the self-developed “AI Brain + 3D Vision” in real-world applications across manufacturing, logistics, quality inspection, and more industries. Mech-Mind’s forward-looking technologies, diverse applications, and practical utility attracted top industry leaders and professionals from various ectors worldwide.

Click to watch the video.

01 From Generalized Picking to AI Quality Inspection: Empowering Full-Process Smart Manufacturing

At the booth, Mech-Mind showcased multiple intelligent robotics applications, giving global attendees an in-depth look at end-to-end automation solutions—from robotic piece picking through high-speed/random bin picking to tire DOT code reading—empowering intelligent upgrades in automotive manufacturing, logistics, quality inspection, and more.

1. AI + 3D Vision-Guided Registration-Free Piece Picking

This application features Mech-Mind’s self-developed registration-free, high-speed generalized AI picking technology. After self-training, the robot autonomously recognizes and picks objects of any material, shape, or pose—demonstrating exceptional generalization. The intelligent stacking detection and pick-planning algorithms empower the 3D vision system to automatically detect the object stacking interference and to generate the optimal picking sequence and angle in real time, ensuring stable picking and avoiding mispicks and dropping. The system can pick up to 1,600 items per hour, which fully satisfies the high-speed sorting requirements of e-commerce, retail, logistics, pharmaceutical, and other sectors.

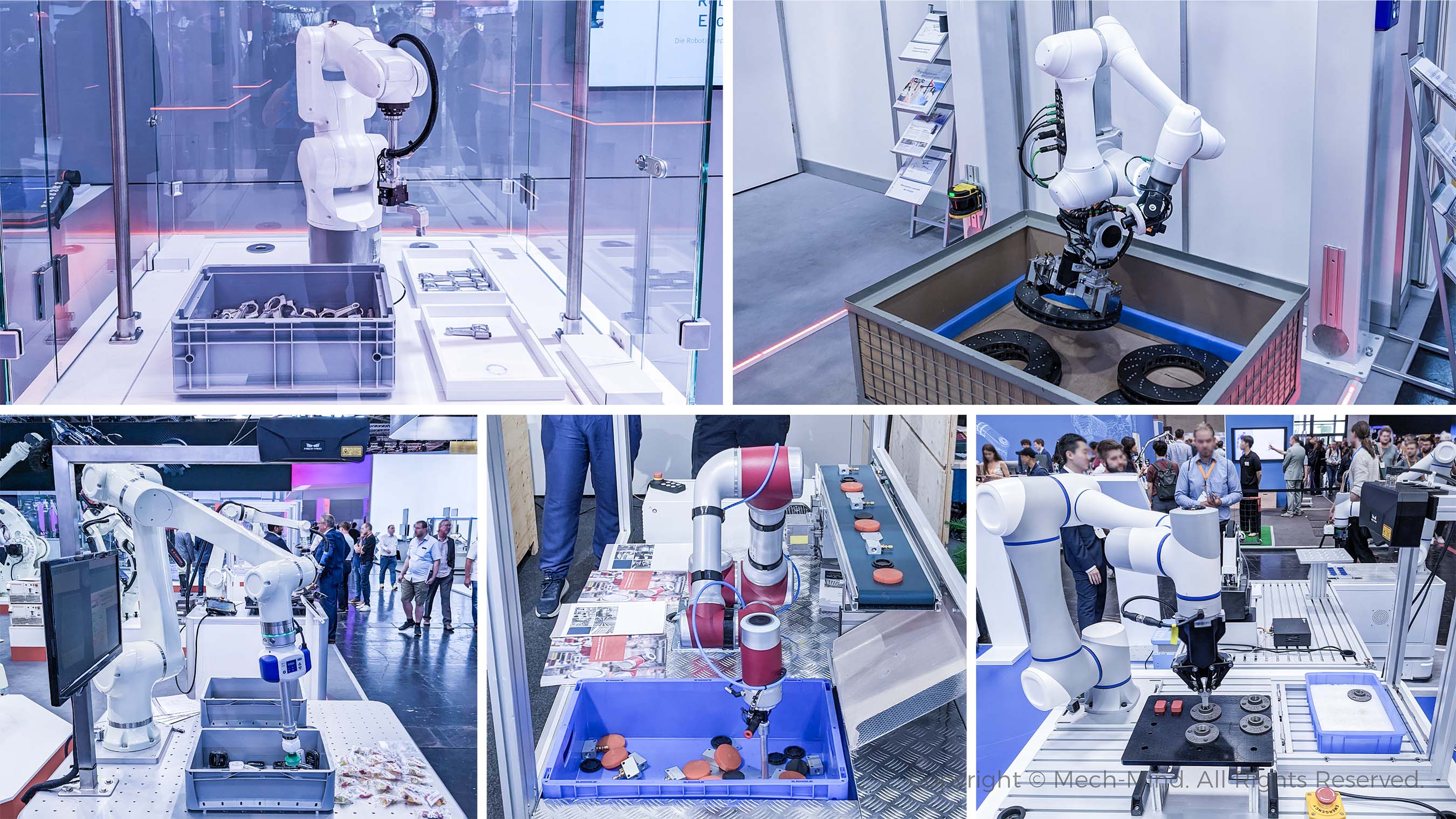

2. AI + 3D Vision-Guided High-Speed Picking of Small Rings

Featuring exceptional accuracy and ultra-fast scanning speed, the Mech-Eye PRO S-GL medium-range structured-light 3D camera delivers high-quality 3D imaging of highly reflective small rings with thin outer diameters in just 0.3 seconds. Integrated with AI software, it quickly and accurately recognizes parts and effectively handles issues such as random stacking, varied orientations, parts tightly stacked in corners, and parts close to bin walls. With a cycle time under 1.9 seconds, it meets diverse actual production requirements.

This application has been deployed at scale across automotive, home appliances, metal and machining, and other industries, which is ideal for random picking and automatic machine tending of small parts.

3. AI + 3D Vision-Guided High-Precision Picking of Hex Nuts

Leveraging Mech-Mind’s AI + 3D vision system, the robot accurately recognizes the randomly stacked small hex nuts with highly reflective surfaces and fine features. Our advanced path-planning and collision-detection algorithms substantially enhance reliability, guiding the robot to pick each nut and place it precisely into the corresponding round hole on the tray. The vision system adapts to hex nuts of various materials, sizes, and shapes—delivering strong generalization and versatility across scenarios.

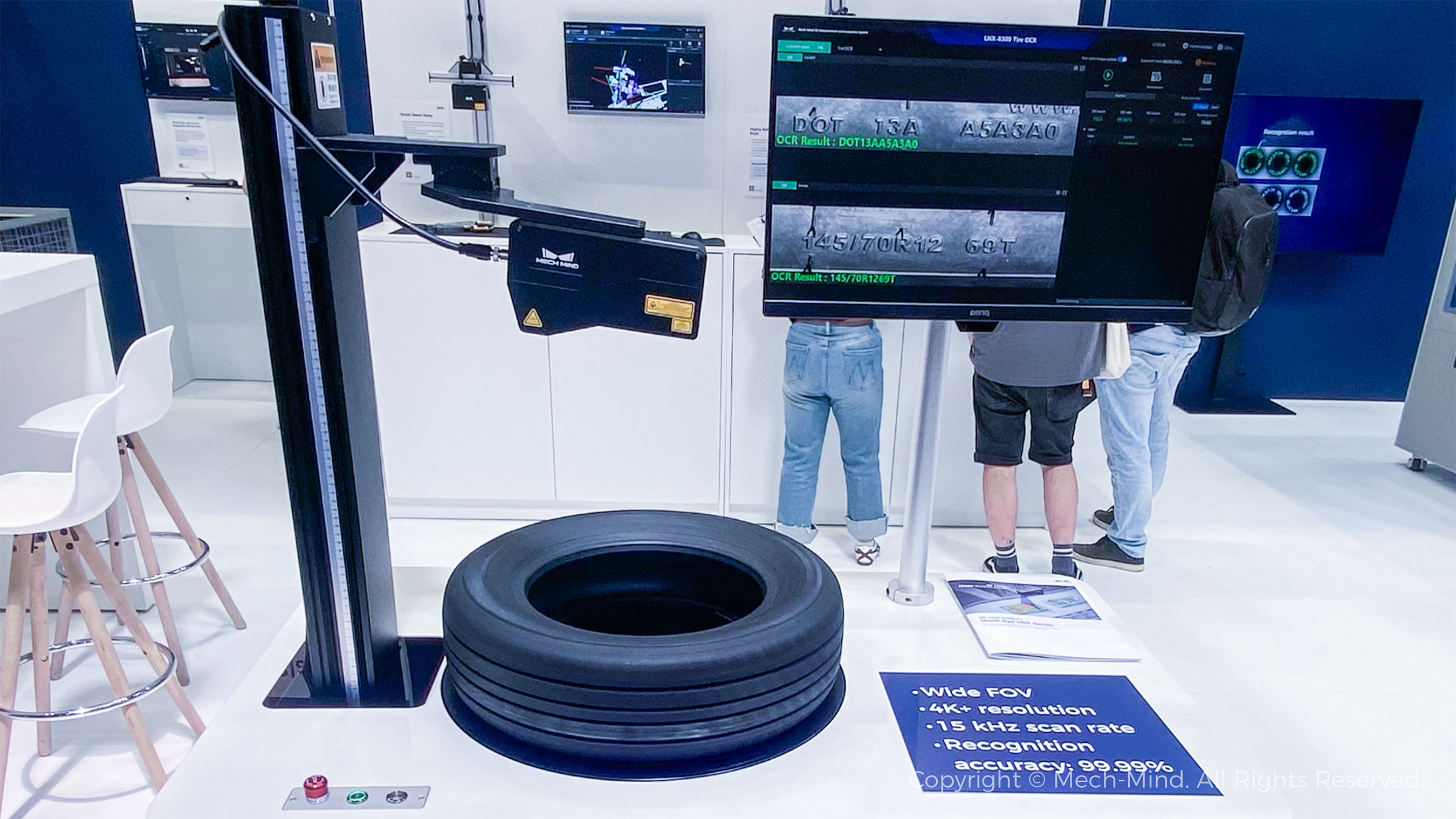

4. Tire DOT Code Reading

Tire DOT code reading demo

Production interface

This unit integrates the Mech-Eye LNX 3D Laser Profiler with Mech-MSR 3D Measurement and Inspection Software into an all-in-one AI quality-inspection solution. The Mech-Eye LNX-8300-GL features 4K+ resolution, ultra-fast scan rate, and expanded X-axis and Z-axis measurement ranges, achieving high-quality 3D imaging of a large, light-absorbing, and intricately textured tire in a single scan.

Mech-MSR has built-in deep learning algorithms and other robust AI capabilities, which can effectively deal with complex or blurred characters, variable positions, background interference, and other complex situations, and accurately extract and recognize characters on tires, achieving a recognition accuracy exceeding 99.99%.

Mech-Mind’s AI-powered all-in-one quality inspection solutions are deployed at scale for character recognition, dimensional measurement, defect inspection, glue-bead inspection, and other 2D/3D quality inspection applications—empowering various industries including automotive, electronics/semiconductor, EV-battery and photovoltaic to improve quality inspection efficiency and product quality.

Joint exhibition units of Mech-Mind and partners

At this event, Mech-Mind also conducted joint demonstrations with several industry-leading partners—showcasing multiple cutting-edge applications including AI + 3D vision-guided random piece picking, picking of highly reflective brake discs, random bin picking of connecting rods, bin picking of black rings, etc.

02 High-Performance Robot “Eye + Brain”, Solving Real-World Challenges

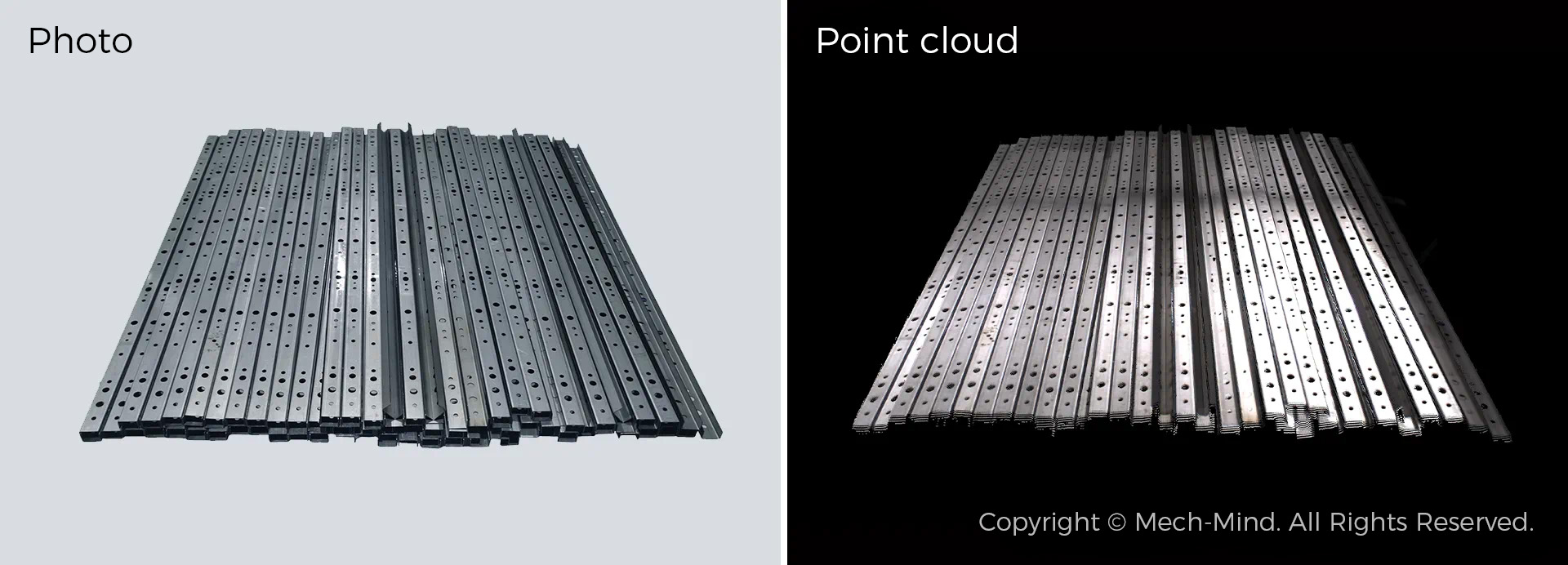

At automatica 2025, Mech-Mind showcased several self-developed general-purpose robot “Eye + Brain” products. Highlights included the Mech-Eye LSR XL-GL large-scanning-range, high-precision industrial 3D camera. Featuring a self-developed and cutting-edge optical design, it considerably reduces fluctuating data along the Z-axis and reliably generates high-precision 3D point clouds of complex parts even at distances exceeding 3 meters, including highly reflective metal parts, light-absorbing plastic parts, and irregular-shaped sheet metals.

The Mech-Eye LSR XL-GL overcomes the distortion and data-loss issues that plague traditional structured-light cameras at ultra-long working distance, better meeting actual production needs in challenging scenarios such as large-size parts and oversized bins. At present, Mech-Eye LSR XL-GL has been deployed at scale in applications such as loading of large battery cells and unloading of stamping parts—providing powerful technical support for improving quality and efficiency in automotive, EV-battery, and other industries.

The Mech-Eye LSR XL-GL accurately generates complete, precise point clouds of complex parts at working distances beyond 3 meters

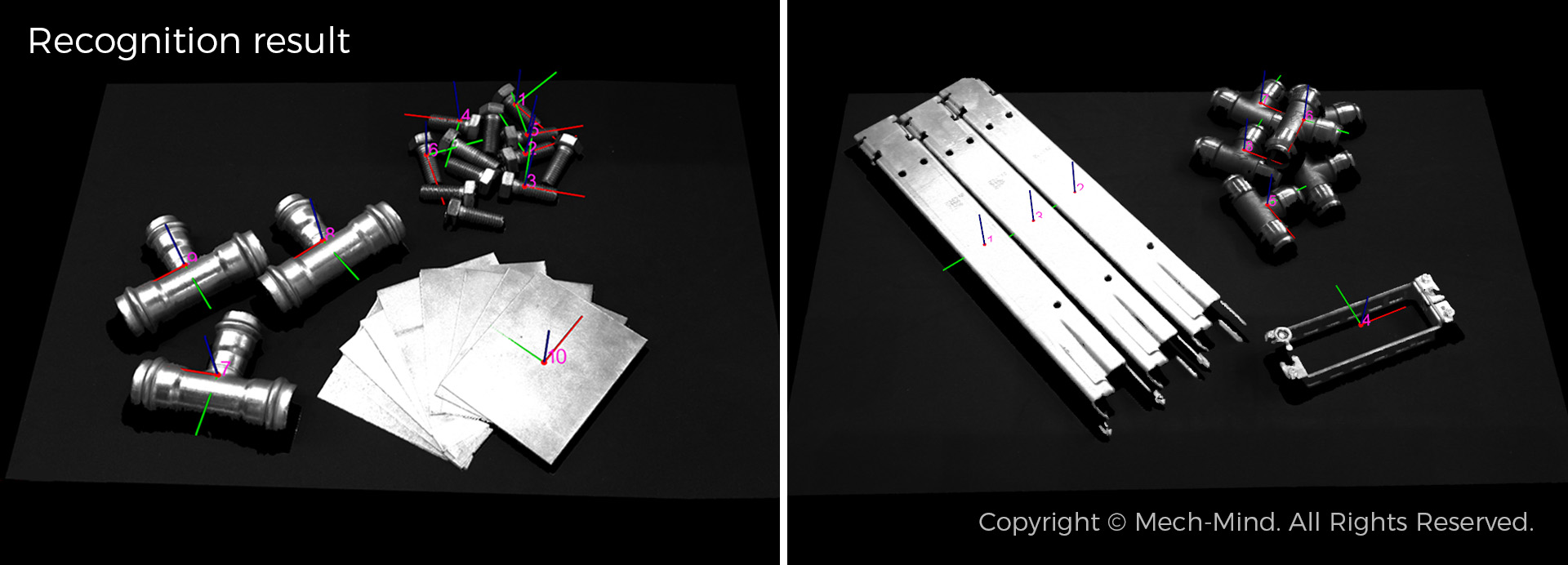

The on-site attendees also had an immersive experience of the powerful recognition capability of Mech-Mind’s self-developed “AI Brain + 3D Vision” products. The accurate recognition results of complex parts including thin sheet metals and randomly stacked three-way pipe fittings impressed the audience deeply. Leveraging robust “Eye + AI Brain”, robots can handle diverse challenging scenarios with ease—boosting production-line efficiency, flexibility and intelligence.

Recognition results of various complex parts

03 Strengthening Overseas Presence, Accelerating Worldwide Business Growth

Adhering to the globalization strategy, Mech-Mind this year participated in Smart Factory + Automation World 2025 in Korea and Automate 2025 in the USA—showcasing cutting-edge intelligent robotics technologies and applications to global customers.

Mech-Mind’s booth at SF + AW 2025 (Korea)

Mech-Mind’s booth at Automate 2025 (the USA)

Since founding the German subsidiary in Munich in 2019, Mech-Mind has established a comprehensive customer service system covering products, sales, delivery, and more. In 2025, to better serve local and European customers, Mech-Mind opened the Munich Showroom & Training Center—a multifunctional space for demonstrations, training, warehousing and meetings. This center further enhances local support and customer experience, accelerating large-scale “AI + robot” deployments across industries and scenarios.

Mech-Mind Munich Showroom & Training Center

Today, Mech-Mind has set up subsidiaries in multiple countries—including the United States, Germany, Japan, Korea—and operates over 10 global business centers, with products available in more than 50 countries and regions. Its self-developed “AI Brain + 3D Vision” products have served over 100 Fortune Global 500 clients, with more than 15,000 deployments worldwide. By pioneering the cross-industry, large-scale, global deployments of its general-purpose robot “Eye + Brain” products, Mech-Mind is driving intelligent transformations across automotive, logistics, metal & machining, EV battery, and more industries.

For more information on Mech-Mind's products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net