The latest release of the brand new 4th generation Mech-Eye DEEP industrial 3D camera, available now, brings enhanced performance in 3D imaging and ambient light resistance. In combination with a more compact design, it meets the demanding range of needs for logistics material handling like never before.

Compared to the previous generation, the new Mech-Eye DEEP offers breakthrough performance in many areas, such as 100% improved ambient light resistance, 65% more compact, 45% less weight, and up to 30% faster scanning speed.

Mech-Eye DEEP highlights at a glance:

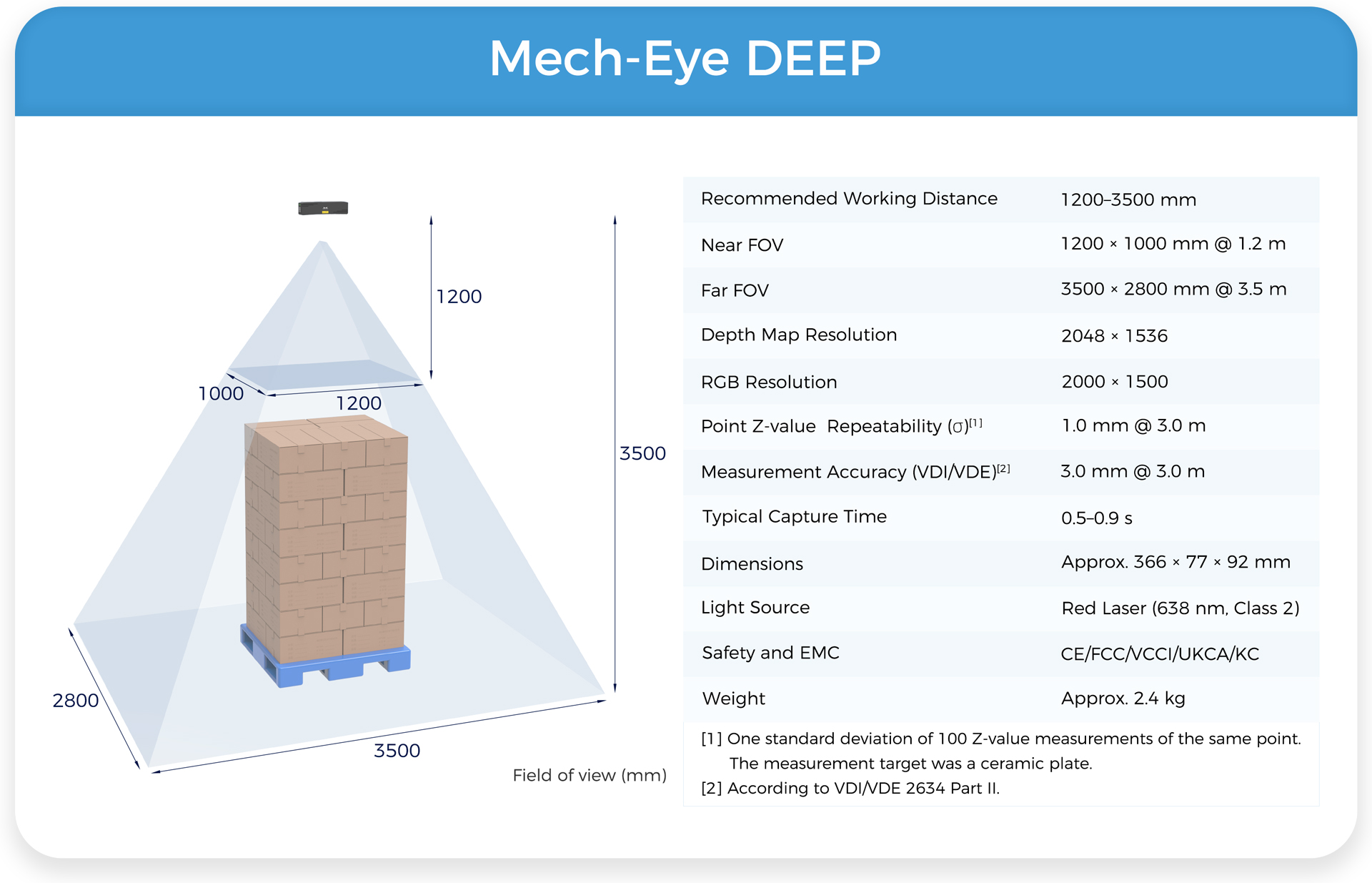

l Ultra large FOV: 3500 × 2800 @ 3.5 m

l Long-range working distance of 1200–3500 mm

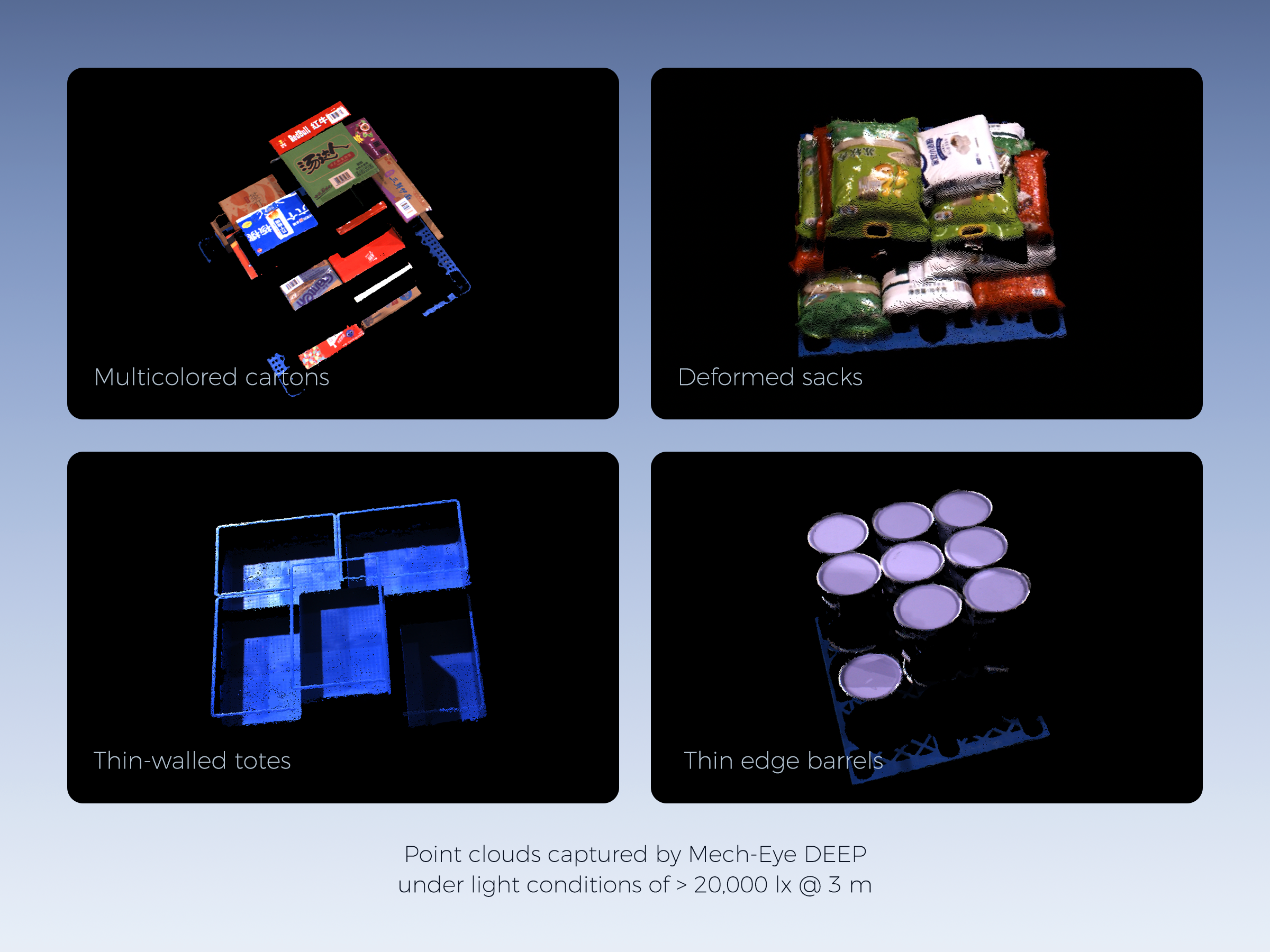

l Robust ambient light resistance: high-quality 3D imaging under > 20,000 lx

l The image acquisition time in the line of logistics can be as short as 0.5 s

l RGB sensor for detection of colored objects

l Compact and lightweight for more flexible mounting options

l CE, FCC, VCCI, KC, ISED, UKCA, RoHS, and NRTL certified to withstand real-world logistics environments

Excellent 3D Imaging and Anti-Ambient Light Performance

The 4th generation Mech-Eye DEEP is designed to deliver impressive colored 3D images in high ambient light conditions for logistics scenarios.

High-Speed Scanning for Ultra-Large FOV Logistics Applications

The Mech-Eye DEEP scans at high speed with an ultra-large field of view, making it ideal for high-speed palletizing and depalletizing.

Large FOV with high accuracy: The Mech-Eye DEEP offers an ultra-large field of view (3500 x 2800 mm @ 3.0 m) and high accuracy (3.0 mm @ 3.0 m), allowing a larger area to be monitored. This makes it ideal for complex material handling tasks, ensuring accuracy even when objects are far away.

Short image acquisition time: Thanks to high-speed structured laser light technology, the time from capture to 3D data acquisition is as fast as 0.5 s (time depends on the actual logistics environment and specific materials), which can help shorten production cycles.

Enhanced Flexibility and Usability for Logistics Automation

The Mech-Eye DEEP's compact size and proven ease of use make it easy to integrate into various logistics production lines or automation projects.

More compact for flexible mounting options: The new Mech-Eye DEEP is 65% more compact and 45% lighter, allowing for flexible mounting options.

Proven industrial reliability in logistics environments: Mech-Eye DEEP is IP65-rated and has passed CE, FCC, VCCI, KC, ISED, UKCA, RoHS, and NRTL certifications. With industry-leading durability features, Mech-Eye DEEP can deliver consistent and reliable performance in harsh logistics environments.

Upgraded Interface for Easier Setup

Mech-Eye DEEP offers multi-language and -platform SDKs. It is compliant with GenICam and GigE Vision and supports Halcon and other machine vision software. The upgraded interface simplifies setup and configuration to better adapt to the ever-changing logistics workflow.

Case Study

One of our customers, a major retailer, is deploying the Mech-Eye DEEP across its sites to optimize its automation scenarios in logistics depalletizing applications.

Using intelligent multi-pick planning and collision detection algorithms, the Mech-Mind 3D vision system guides the robot to pick and stack multiple cases in high ambient light conditions of logistics scenarios, maximizing the number of cases picked to continuously improve line efficiency.

'We are working with Mech-Mind to make 3D vision cameras part of our automation infrastructure to reduce production cycle time and improve productivity at various stages of logistics material handling,' said our customer, 'We expect Mech-Mind's 3D vision cameras and systems to play a critical role in helping us realize our vision.'

The new Mech-Eye DEEP is designed for large FOV palletizing and depalletizing applications across warehouse and factory floors. The significant improvement to the Mech-Eye DEEP allows it to handle challenging logistics scenarios, ensuring uninterrupted performance and faster ROI.

In addition to the high-performance Mech-Eye industrial 3D cameras, Mech-Vision Machine Vision Software, and Mech-Viz Robot Programming Software, the company's proprietary robotics software suites, will also support the Mech-Mind partner ecosystem, enabling global robotics integrators to quickly and easily implement a wide range of typical applications.

The Mech-Eye DEEP industrial 3D camera is now available for order. For more information about Mech-Mind DEEP or Mech-Mind's AI + 3D vision solutions for industrial robots, please get in touch with us at info@mech-mind.net.