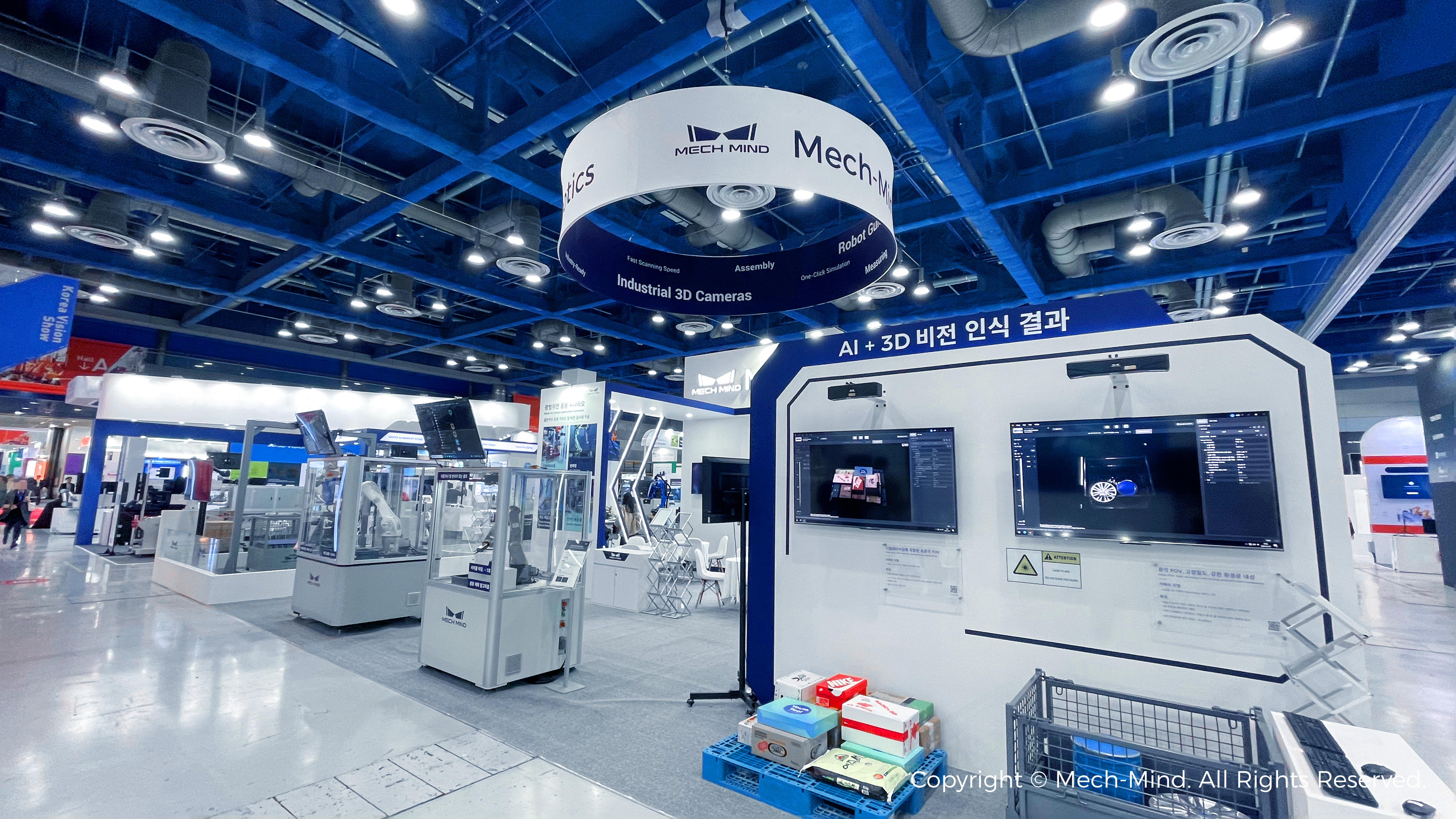

Mech-Mind’s booth at SF+AW 2024

From March 27th to 29th, the Smart Factory + Automation World 2024 (SF+AW 2024) was held at the Convention & Exhibition Center in Seoul, South Korea. As one of Asia's most influential industrial automation exhibitions, SF+AW 2024 brought together over 450 automation and robotics companies. These companies presented their latest machine vision and robotics technologies, attracting around 70,000 audiences at the trade fair.

Mech-Mind Robotics, a global leader in AI and 3D vision, made its debut at SF+AW 2024. At the event, Mech-Mind released the Mech-Eye LNX-7500 Series and Mech-MSR 3D Measurement and Inspection Software. The combination of these two products is perfect for high-precision 3D measurement and inspection. We also presented other high-performance 3D sensors and showcased the power of AI and 3D vision through robotic applications in different scenarios.

Click to watch the video.

01 Quality Inspection Powered by AI

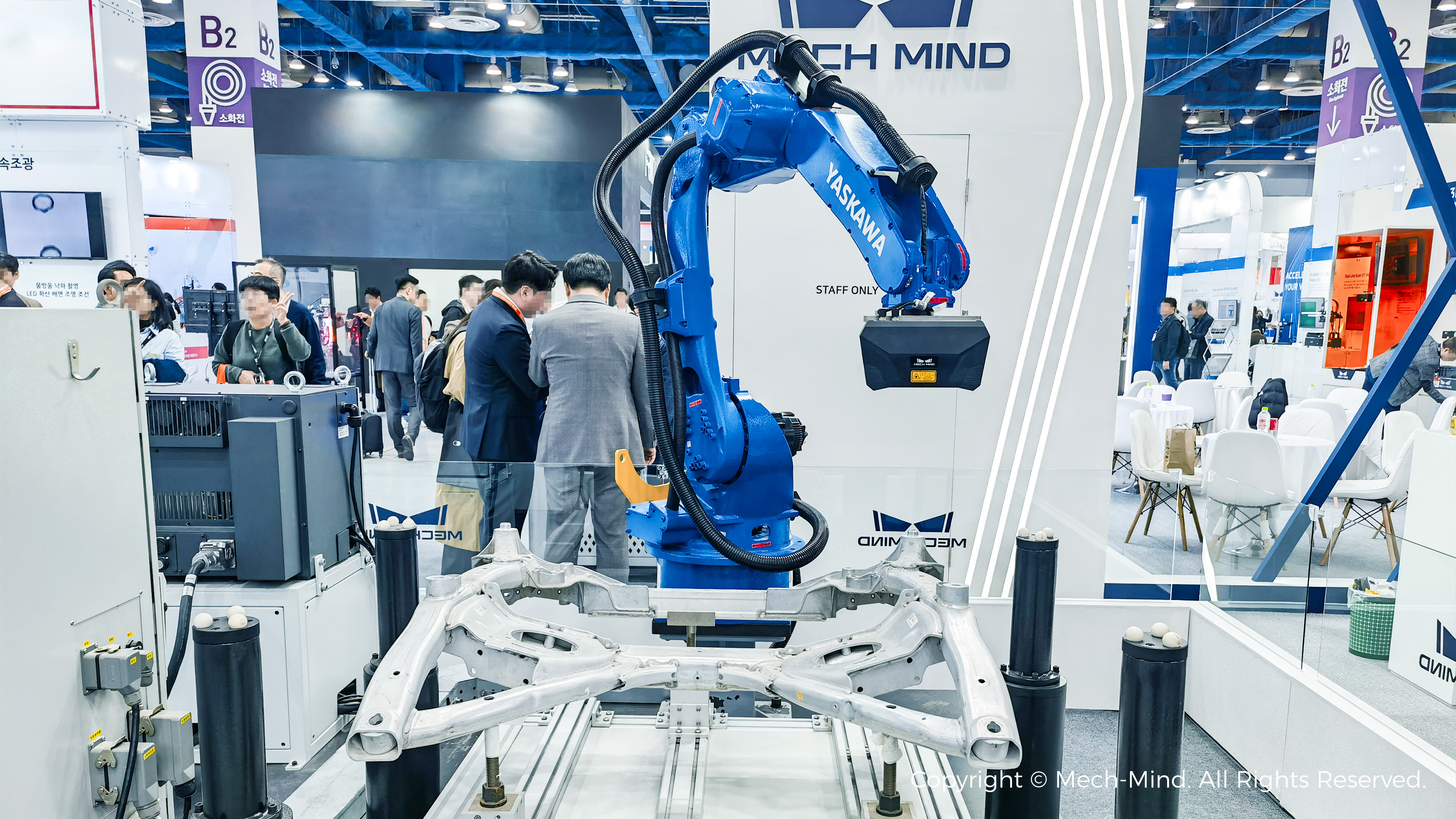

Inline measurement demo

Measurement interface

Industrial robots equipped with the Mech-Eye Industrial 3D Camera UHP-140 can perform non-contact flexible measurements of subframes. The Mech-Eye UHP-140 adopts self-developed fusion imaging algorithms and structured light imaging algorithms, easily dealing with the imaging interference caused by irregularly shaped parts, reflections, and blind spots. The advanced measurement algorithms, combined with a real-time shoot-and-go approach, enable accurate single-point measurement in as short as 2 seconds.

Mech-Mind's inline measurement solution has been deployed in numerous Tier-1 automobile manufacturers, helping customers achieve 100% inspection, high flexibility, and high-speed inline measurement. This guarantees high-standard and highly efficient delivery for customers.

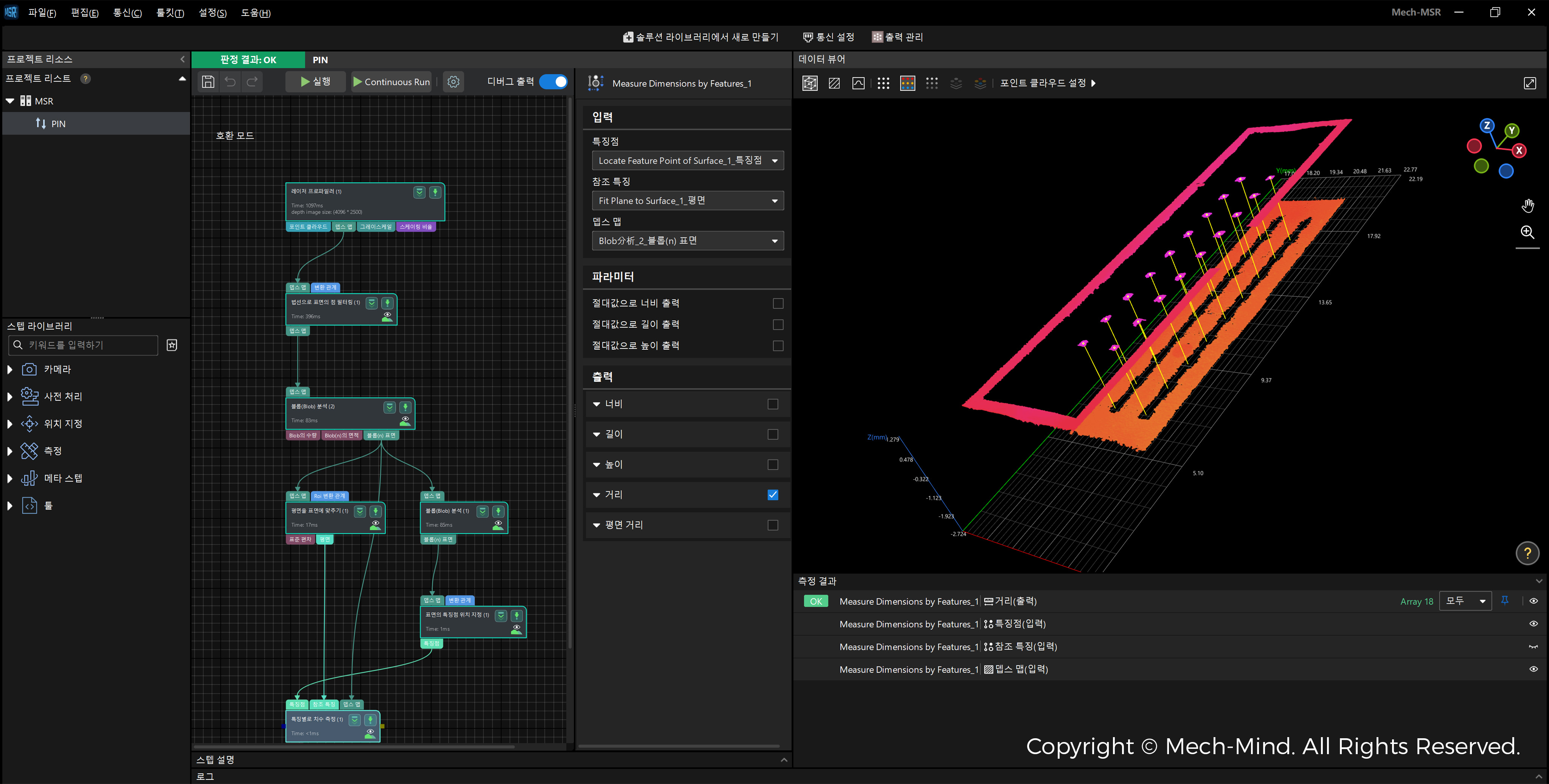

Pin height measurement

Mech-MSR measurement interface

Mech-Mind demonstrated how 3D vision technologies empower quality inspection. The LNX-8000 series combines 4K resolution and 15 kHz blazing fast scan rates, making it possible to scan tiny features at a fast speed. The LNX-8030 was presented to inspect the height differences of connector pins. The newly launched LNX-7500 series also delivered impressive performance. Combined with the Mech-MSR, the LNX-7580 was displayed to inspect smartphone midplate flatness, and the LNX-75300 to carry out dimensional measurements of battery modules. On each screen, visitors can view the measuring results of these applications.

Mech-MSR incorporates a rich set of powerful measurement and inspection algorithms and features a user-friendly interface that facilitates the quick deployment of various 3D measurement and inspection applications. The LNX 3D laser profilers, combined with the Mech-MSR, can measure and inspect height, flatness, and geometric features of various parts, which has been widely applied in PV, EV battery, electronics, semiconductor, and automotive industries.

02 Vision-Guided Robotic Picking Applications for Flexible Production

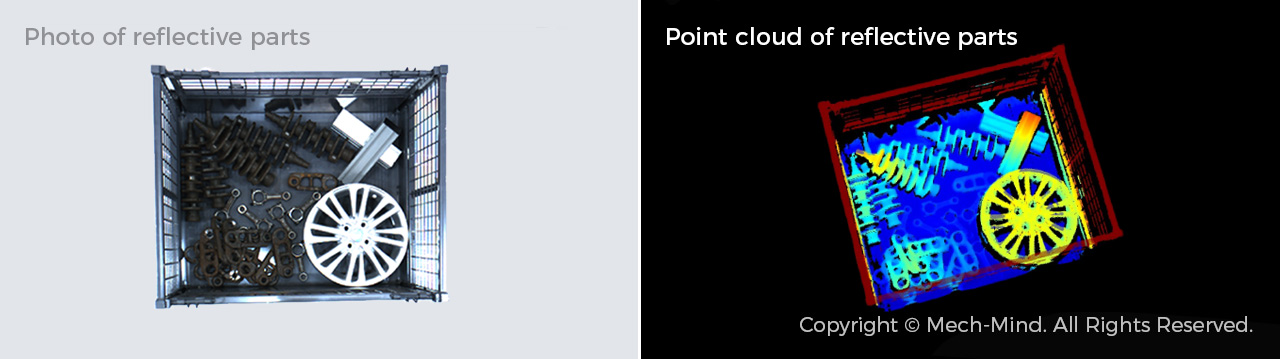

Mech-Mind has independently developed 3D deep learning technology that can generate DL models based on the digital models of the parts. Users do not need to collect samples or perform manual annotation. After importing the generated models into the vision projects, they can easily obtain the pose of parts in complex scenarios (e.g., deep bins with reflections or deep bins with irregularly shaped parts), thereby significantly improving the efficiency of part recognition.

The perfect combination of Mech-Eye industrial 3D cameras' excellent imaging capability and the self-developed 3D DL algorithms greatly improves the recognition rate of complex parts and the clearing rate of bin picking. This boosts flexibility and productivity on production lines for customers across automotive, metal&machining, and other industries.

At the booth, the high-speed bin picking demos were the most attractive. In addition to the highly reflective metal parts, Mech-Mind's 3D vision applications also showed how to handle the picking of bolts and small rings.

Random bin picking of bolts

Random bin picking of small rings

Clear and detailed 3D point clouds created by Mech-Eye PRO S ensure accurate recognition of 0.18-inch rings. The robust algorithm calculates the ideal picking strategy to cope with some complex situations and prevent any collisions. Rings tightly stacked in the corner and those close to the bin wall are no longer tricky in the vision task. The cycle time is as short as two seconds, meeting speed requirements in the practical production line.

Piece picking

Mech-Mind's technology and ability to handle high-SKU inventories can be applied across many e-commerce fulfillment applications. The excellent 3D vision system can effectively handle a wide range of items, including bottles, boxes, transparent and dark objects, as well as objects of various sizes and complex patterns, without requiring previous registration.

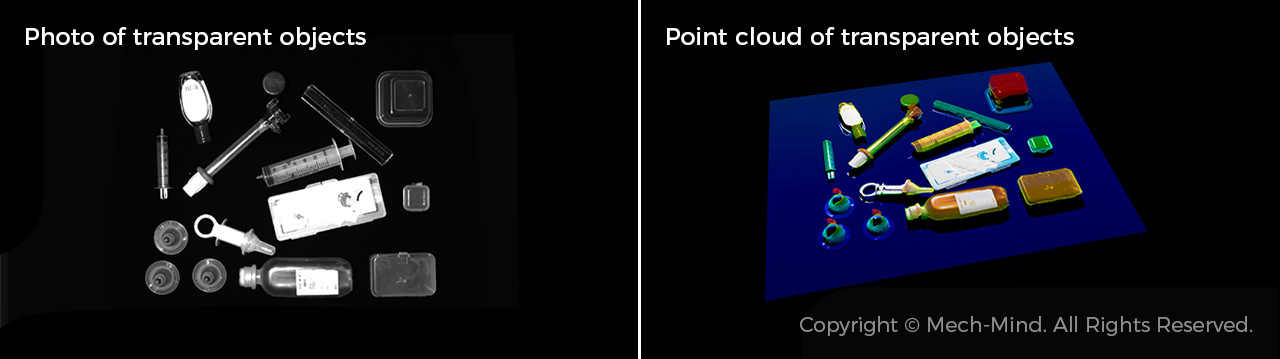

03 Precise Imaging for Reflective and Transparent Objects

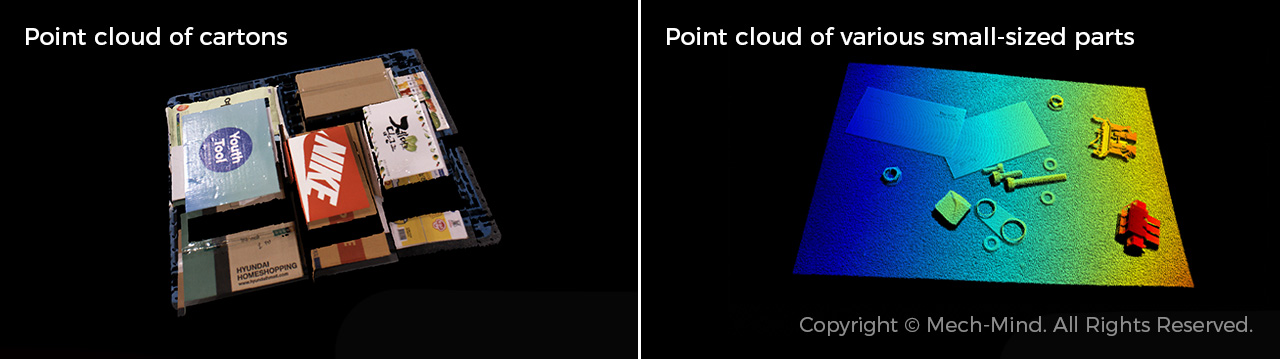

Mech-Mind also exhibited a range of flagship industrial 3D cameras, including Mech-Eye LSR L, Mech-Eye PRO S, Mech-Eye NANO, and Mech-Eye DEEP, demonstrating their high-quality imaging performance for various typical parts such as transparent, highly reflective, and complex-patterned objects.

The newly upgraded Mech-Eye PRO S, equipped with self-developed imaging algorithms, can generate high-quality 3D point clouds

for various transparent objects such as beverage bottles, medical test tubes, saline bags, and glass boxes.

Mech-Eye LSR L offers a reflective mode, which greatly enhances the imaging quality of reflective objects.

This mode improves the accuracy of point clouds by 90% compared to the previous modes.

Point clouds of cartons and various small-sized parts

Mech-Mind has opened an office in Seoul, South Korea, to better support local customers with sales, technologies, and professional training. By providing advanced products and comprehensive services, the company assists partners in Korea and throughout the Asia-Pacific region in implementing more intelligent robot applications in diverse manufacturing scenarios.

Mech-Mind's products are applied in more than 50 countries and regions all over the world, achieving rapid growth and excellent customer approval in the global market. Mech-Mind will adhere to productization, globalization, and ecosystem development, working together with global partners to accelerate the implementation of AI and 3D vision technologies.

For more information:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net