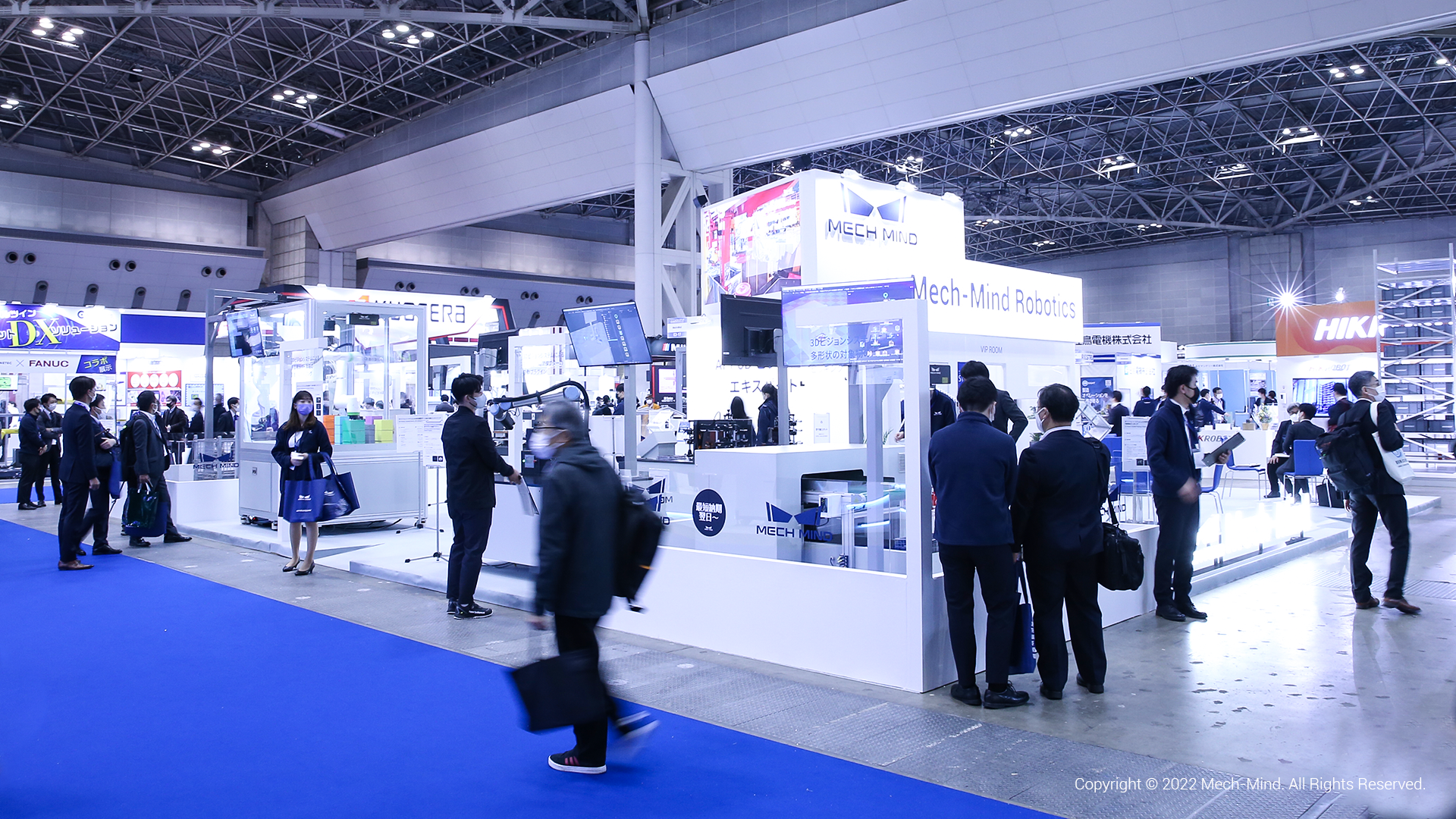

The iREX 2022 was concluded with great success. The 4-day event from March 9-12 in Tokyo offered over 62,000 visitors a close-up experience with more than 600 companies and organizations all over the world.

As one of the largest robot trade shows in the world, iREX exhibited the latest robot technologies and products, providing manufacturers and companies worldwide a perfect opportunity for exchanging insights and expanding new business.

AI + 3D Robot Solution Caught the Eye at iREX 2022

Robots combined with the ever-evolving robot technologies are indispensable for industrial automation. Upholding the theme of 'the way towards a friendlier society, bridged by robots', iREX 2022 offered space for more than 3000 booths to showcase the ongoing robot technologies and the latest trends in robotic automation.

The AI + 3D vision-guided robots, among all the robot technologies and products shown at many booths, attracted the most visitors on-site, making Mech-Mind Robotics one of the most popular exhibitors at iREX 2022.

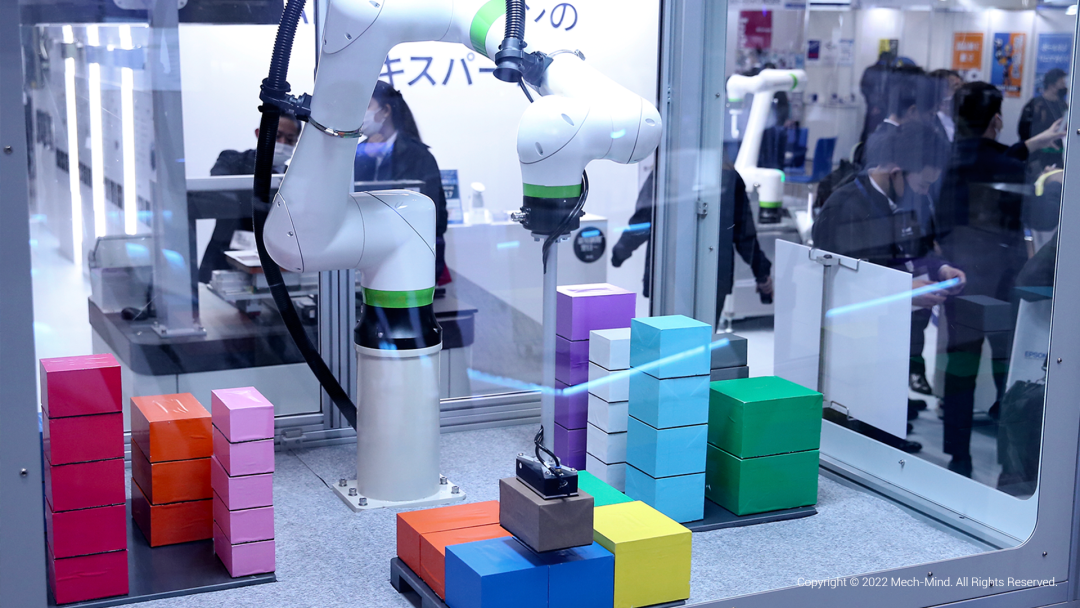

Its AI + 3D vision-guided bin picking solution was extremely eye-catching as the vision-guided robots could handle the most challenging objects in the way of outstanding flexibility, excellent stability, and fast cycle time.

Meanwhile, Mech-Mind, which shared one of the largest booths at iREX 2022, also exhibited its flagship products — Mech-Eye industrial 3D cameras and its all-in-one industrial solutions, including mixed case palletizing, parcel induction, high-precision measurement, defect detection, etc. And its innovative solutions have been deployed at thousands of factories and warehouses in logistics, manufacturing, the food industry, and more.

Scalable and Reliable AI+3D Industrial Robot Solution

【3D Vision-Guided Bin Picking of Randomly-Piled Track Links】

Core Advantages:

· Mech-Eye Laser L 3D camera with an extended field of view and high precision can effectively tackle the typical ambient interference (10000 - 20000 lx) and handle issues like reflective surfaces, black color objects, and complex structured objects;

· Intelligent path planning algorithm enables collision-free bin picking of randomly-piled workpieces with high accuracy.

· Intelligent picking algorithm supports multiple TCP clamps with automatic switching, smart planning of the best gripper spot.

Typical Scenarios

Picking and feeding workpieces from deep bins is one of the most typical scenarios in engineering, auto parts, manufacturing, home appliances, steel, machine tools, etc.

【3D Vision-Guided EV Car Charging Adapter Plugging】

Core Advantages:

· Mech-Eye Nano palm-sized industrial 3D camera is lightweight with high flexibility, compatible with mechanic arms of hybrid robots;

· Mech-Eye Nano of high precision delivers incredible ambient light resistance performance, can generate high-quality point cloud data of black charging socket even with the strong interference of outdoor sunlight (> 60000 lx);

· Coupled with the Mech-Mind 3D vision-guided system, the robot can locate the charging socket with high precision and plug it in to charge the vehicle accurately.

Typical Scenarios

New energy, electric vehicle charging, automobile refueling, assembly, screwing, and high-precision picking scenarios.

【3D Vision-Guided Mixed Case Palletizing】

Core Advantages:

· High-precision Mech-Eye industrial 3D camera can produce high-quality point cloud data for cartons of different sizes and colors;

· The optimal palletizing pattern and movement path are generated in real time, and cases are picked one by one and placed on the pallet when the carton specifications and incoming order cannot be obtained in advance;

· Intelligent path planning algorithm enables the best-adjusted angle for robot operation to avoid collisions;

· Support easy access to AGV/AMR, transmission control system, and WMS system.

Typical Scenarios:

Typical applications include e-commerce, supermarket, medicine, express delivery, and other fields; Suitable for typical scenarios such as express cage trolley loading, inbound and outbound processes in the warehouses.

【3D Vision-Guided Parcel Induction】

Core Advantages:

· High-quality point cloud data for various randomly-piled express parcels (cartons, soft bags, foam envelopes, etc.);

· Able to deal with complicated situations such as randomly-stacked and scattered pieces;

· The speed is up to 2.2 seconds per piece, which perfectly fulfills user needs in real scenes;

· Highly compatible with logistics equipment such as AGV and cross belt sorter.

Typical Scenarios:

Express package grabbing, package feeding, etc.

【3D Vision-Guided Piece Picking of Multi-SKUs】

Core Advantages:

· Registration-free. Support bottles, boxes, transparent packing, small, irregular, and dark objects;

· High flexibility for new goods;

· High processing speed: A single workstation can process 1200 pieces/hour.

· With the intelligent stacking algorithm, robots can detect the position of target objects in real time to ensure stable picking and avoid mispicks.

· Smart planning of the optimal picking spots on the basis of the recognition results.

· Support easy access to AGV/AMR, transmission control system, and WMS system.

Typical Scenarios:

Typical applications include e-commerce, supermarket, medicine, express delivery, food and beverage, and other fields.

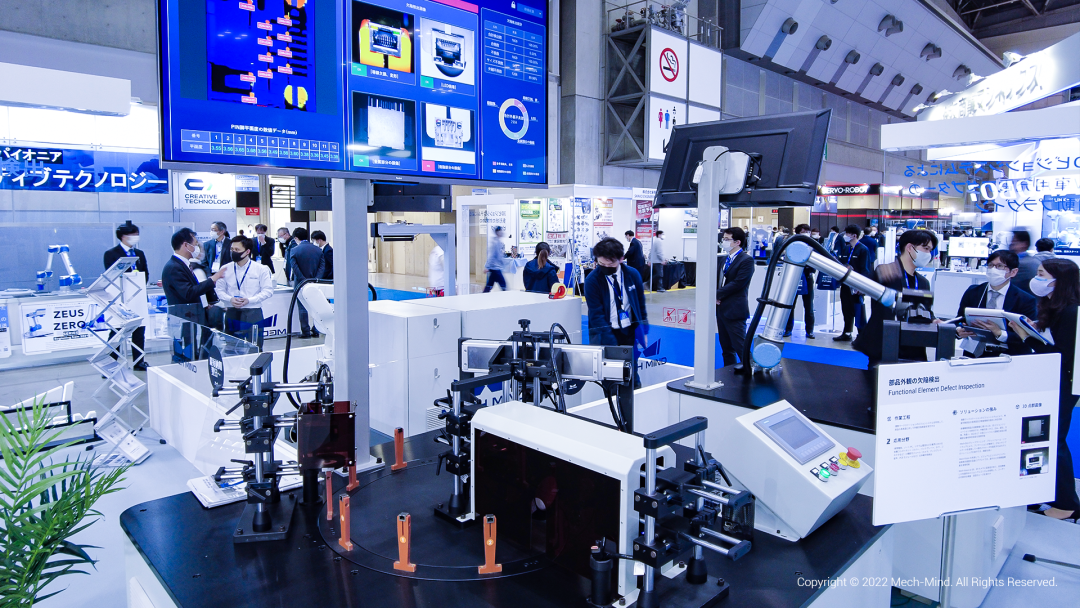

【Electronic Component Defect Detection】

Core Advantages:

· Work stations are integrated with several vision systems to fully detect all features of the incoming electronic components;

· Automatic detection for all kinds of precision components.;

· Integration with 2D and 3D vision to generate high contrast images for all kinds of defects, including scratches, indentations, deformations, impurities, deficiencies, etc.;

· Mech-DLK deep learning platform software is versatile and easy-to-use, also integrates model verification to improve efficiency;

· Mech-Vision can be compatible with almost all mainstream 2D/3D cameras, allowing fast deployment of defect detection applications and production lines.

Typical Scenarios:

Can be utilized in detecting all kinds of defects in electronic components (cover plates, backplanes, tabs, connectors, etc.) and functional modules (camera module, display module, acoustic module, PCB module, etc.) in cell phones, laptops, lithium battery, and other industries.

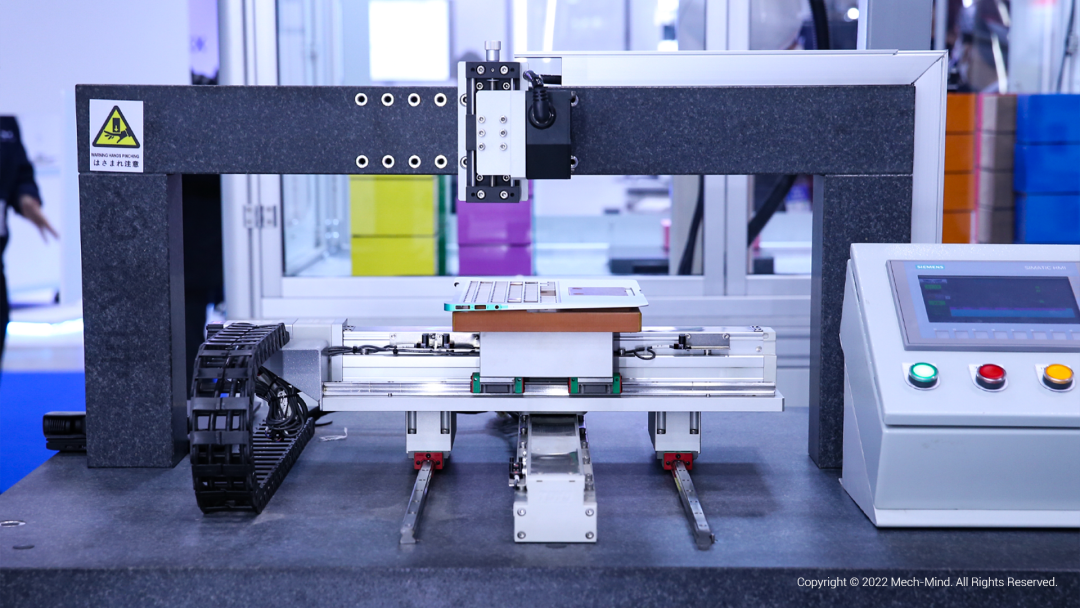

【Notebook C Casing Flatness Measurement】

Core Advantages:

· It can precisely measure the geometrical qualities of notebooks, cell phones, tablets, AIO PC, and other consumer electronics, including 2D features (length, width, and circle diameter) and 3D features (altitude difference, flatness, and profile).

· Micron-grade precision industrial 3D camera integrating super-advanced point cloud processing techniques and 3D measurement algorithms enables high-precision assembly production.

· Mech-Vision provides a fast setup of typical high-precision measurement applications to achieve fast deployment of your projects.

Typical Scenarios:

High-precision measurement of the flatness, altitude difference, profile, and other geometrical qualities of notebooks, cell phones, tablets, AIO PC, and more 3C products.

Mech-Mind Is Expanding Footprint and Capacities Worldwide

Mech-Mind has been committed to its global layout, running the business in more than 50 countries and regions. Mech-Mind Japan was established in 2021 and is dedicated to assisting robot solutions providers/integrators in creating various excellent intelligent robot applications in a shorter period, with superior quality and smart investment in Japan and Asia. In this exhibition, Mech-Mind received nearly a thousand sales leads from more than ten countries and regions, several well-known enterprises put forward their purchasing intentions for products, and a cooperation consensus was reached with many celebrated robot manufacturers.

At present, Mech-Mind has successfully delivered 1000+ cases globally, including new energy, automotive, construction machinery, logistics, 3C, etc. Mech-Mind will continue to be dedicated to technology iteration and product innovation, devoted to delivering expansively practical intelligent industrial robot solutions, enhancing industrial automation upgrades while stably gaining momentum in its global deployment, pushing forward innovative development in advanced manufacturing globally.

Mech-Mind Japan

Address: 東京都港区芝二丁目2番14号 一星芝ビルディング 1F

Tel: 03-6809-5433

Fax: 03-6898-5948

Postcode: 105-0014

Email: info@mech-mind.net