Mech-Mind is excited to announce the official release of its new Mech-MSR 3D measurement and inspection software. Mech-MSR is our next-gen AI software designed for creating end-to-end inspection applications deployed on Mech-Eye LNX 3D laser profilers. Leveraging a no-code graphical user interface and robust built-in algorithms, Mech-MSR enables users to tackle a wide range of inspection tasks with unprecedented efficiency and precision.

Key features making Mech-MSR stand out:

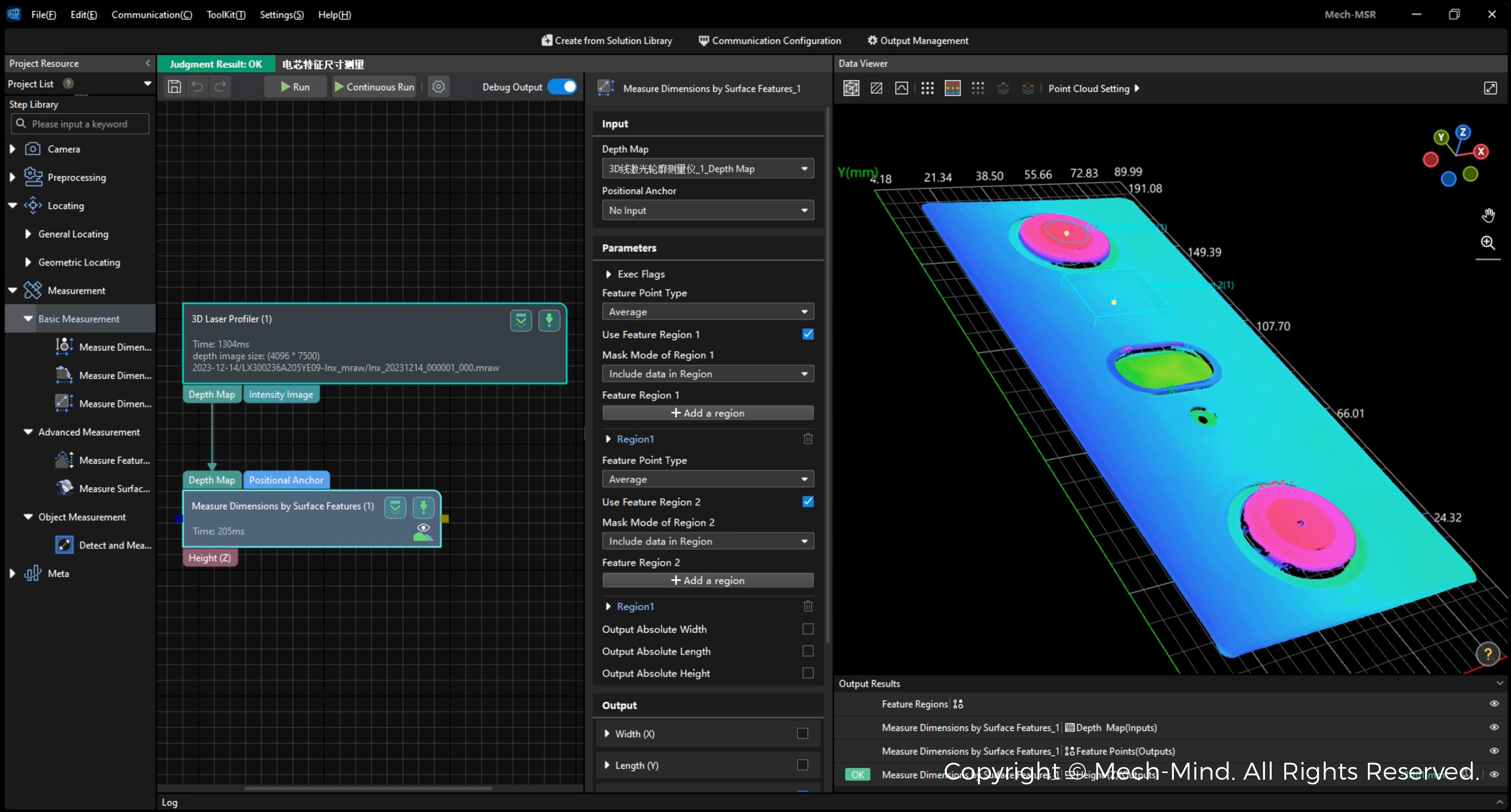

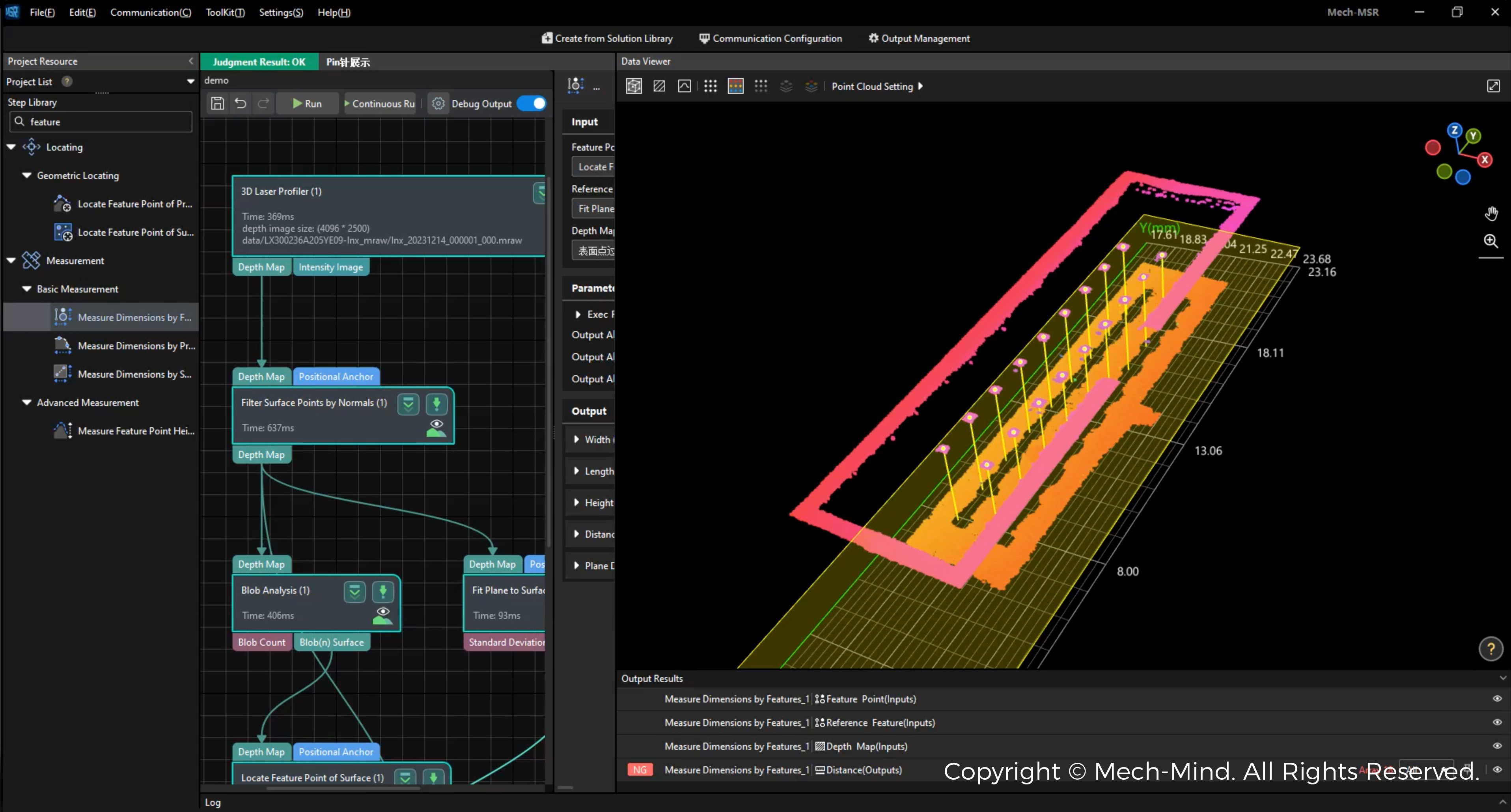

• Easy-to-navigate GUI design and 100% visualization of data that facilitate intuitive creation of inspection solutions without writing a line of code.

• Built-in advanced algorithms and configuration tools for exceptional out-of-the-box inspection performance.

• Precise measurement capabilities based on multi-dimensional measurements (2D/3D).

• Seamless connection to and operation on the Mech-Eye LNX 3D laser profilers for rapid setup.

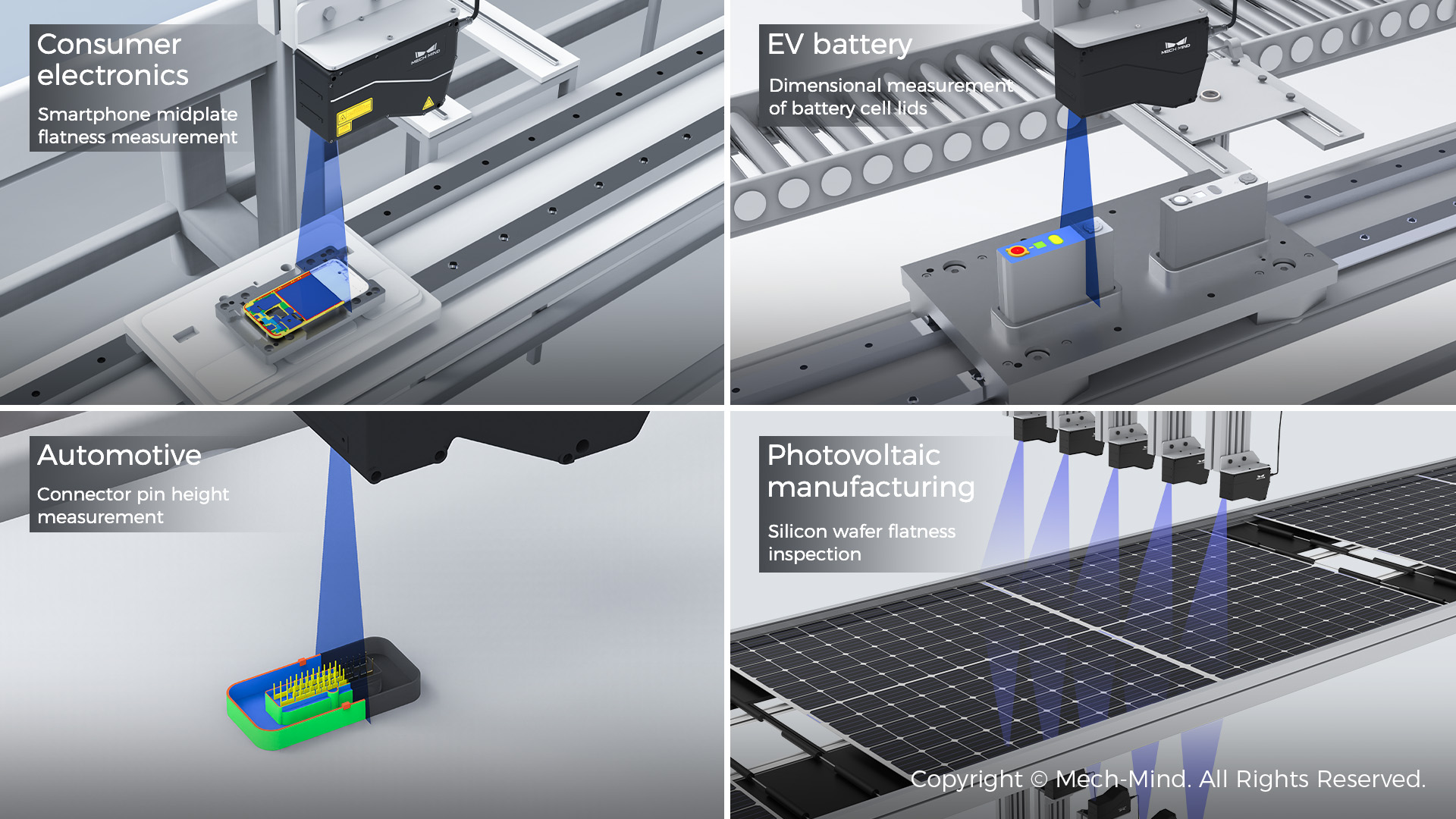

Mech-MSR, combined with Mech-Eye 3D laser profilers, is the go-to choice for inspection applications in various industries, including semiconductors, consumer electronics, EV batteries, automotive, and photovoltaic manufacturing. This perfect combination helps clients enhance production efficiency and product yield while reducing costs.

01 Core Benefits and Features of Mech-MSR

Experience Unparalleled Efficiency with Mech-MSR's No-Code GUI and Robust Measurement Algorithms

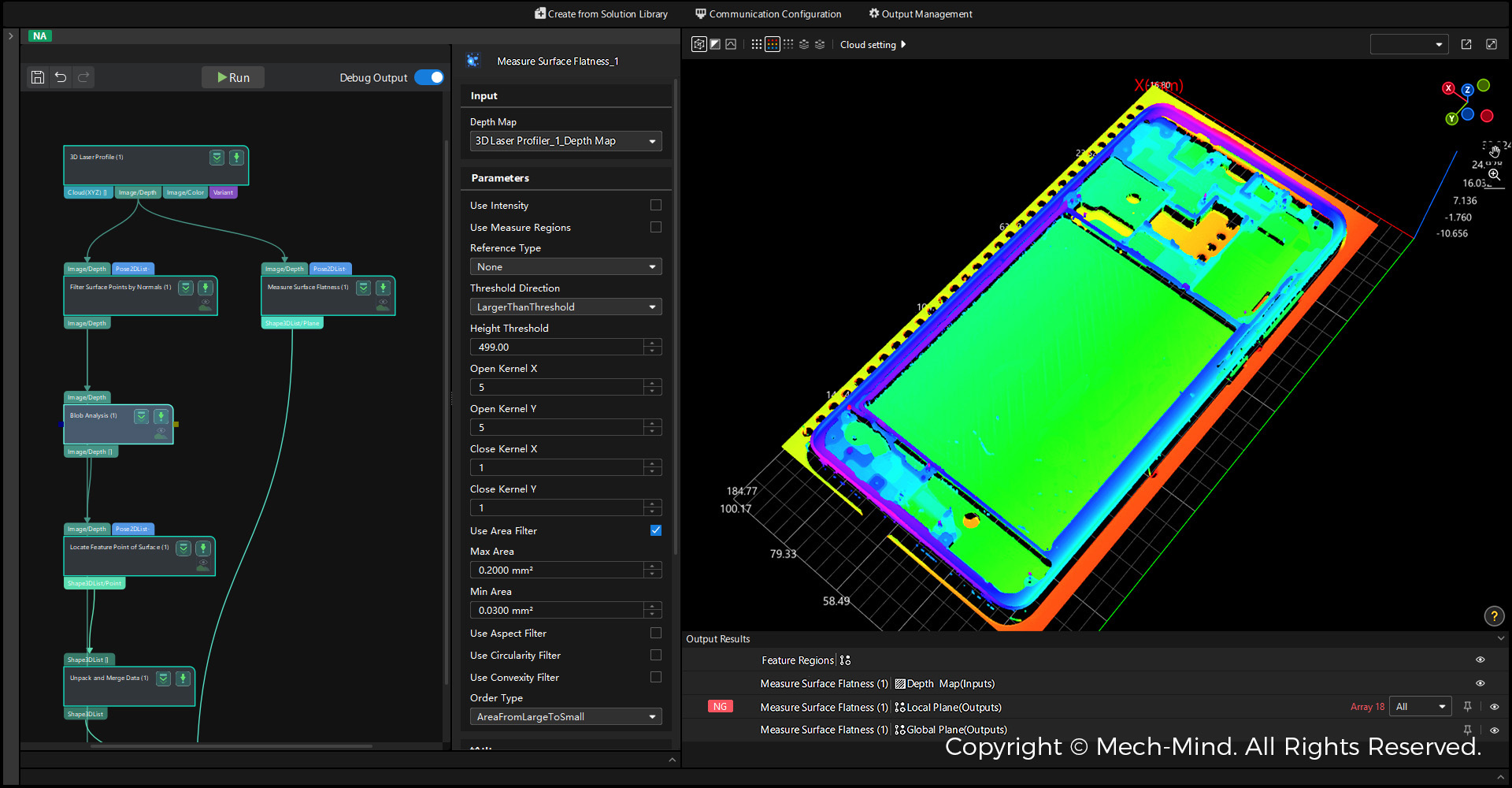

When developing Mech-MSR, Mech-Mind has prioritized the user experience. Our software features a graphical, modular, and user-friendly interface that allows users to effortlessly navigate through various inspection and measurement applications. The interface also includes a 3D visualized parameter configuration function, which enhances tuning efficiency by presenting surface, profile, and other data in a clear and concise manner.

Furthermore, Mech-MSR encompasses a range of measurement algorithms, such as alignment and point cloud preprocessing, ensuring optimal measurement efficiency and accuracy. Users also have the flexibility to customize evaluation methods to meet specific production standards. After completing measurements, users can review and analyze the results to further optimize production processes.

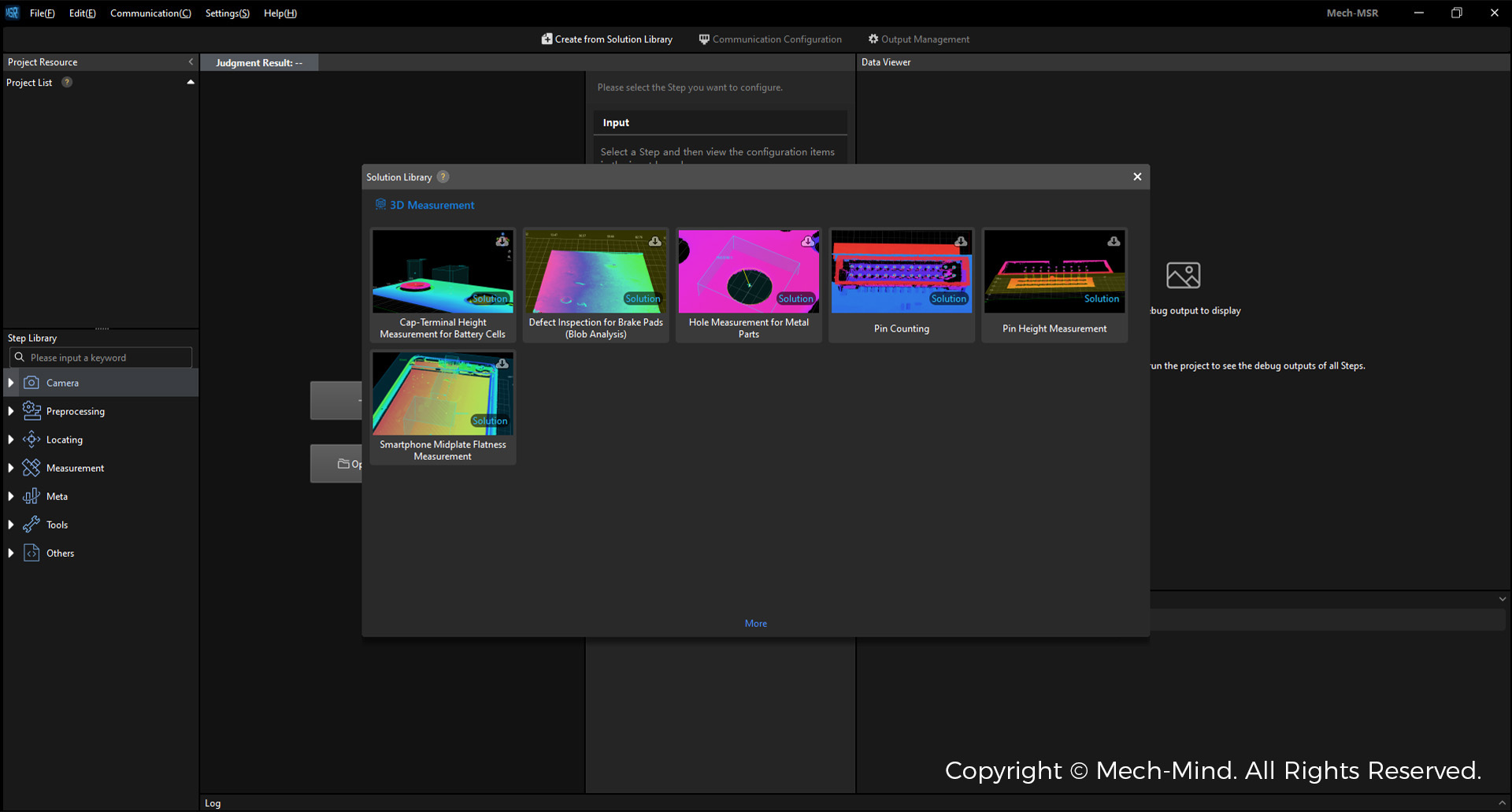

Benefit from a 2-Hour Project Deployment with Our Powerful, Easy-to-Use Software

Mech-MSR significantly simplifies the setup and deployment process, enabling users to deploy their inspection projects in just one step*. It offers an extensive solution library, allowing users to browse existing solutions and efficiently deploy them on their inspection projects.

Moreover, Mech-MSR is fully compatible with all Mech-Eye LNX 3D laser profiler models. All these unique features ensure that inspection projects can be completed in as little as 2 hours*, meeting the demands for speed and accuracy.

*In accordance with the actual project circumstances.

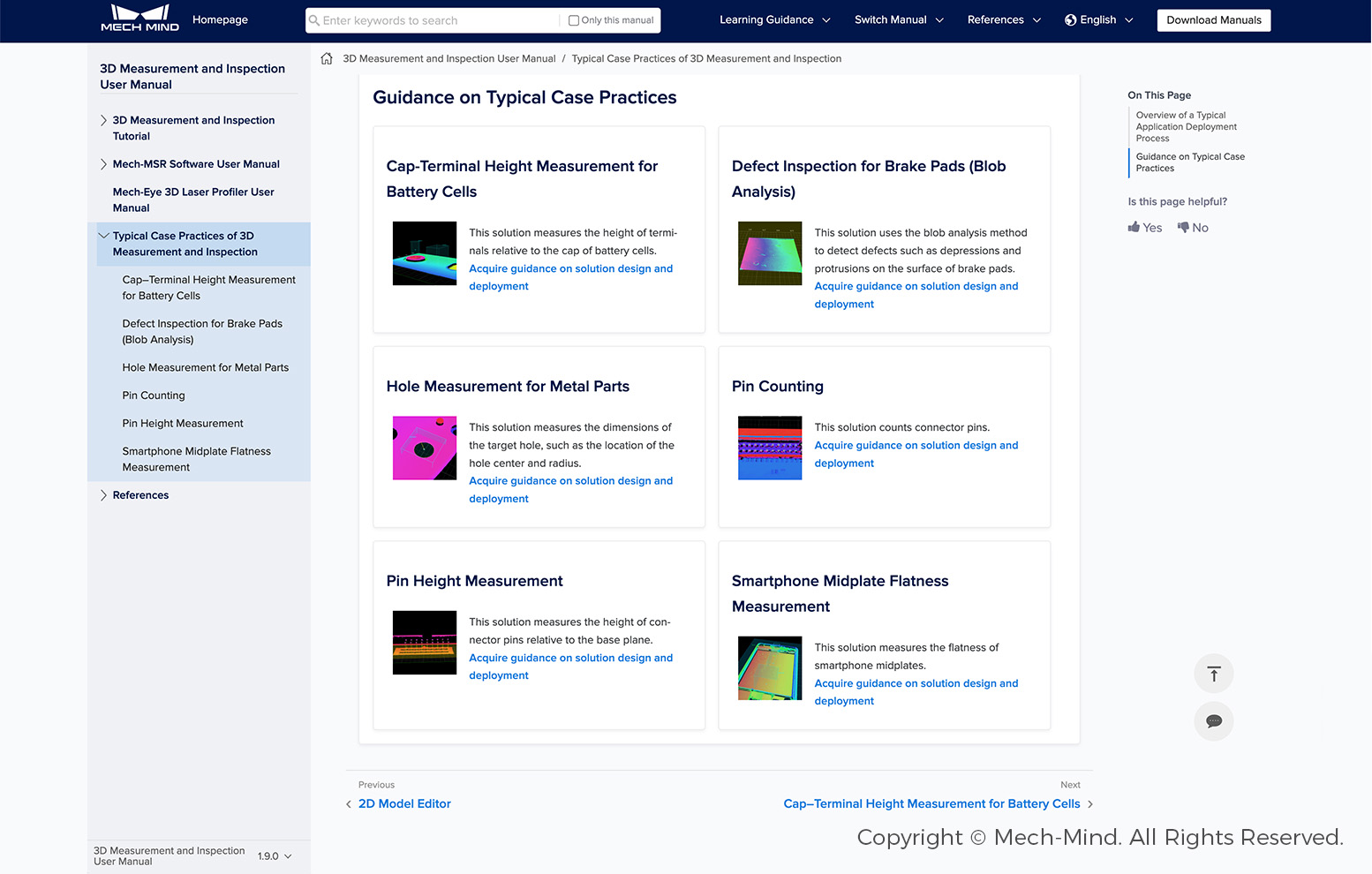

Unlock Your Full Potential with Our Comprehensive Documentation and Technical Support

The Mech-MSR installation package provides step-by-step guidance for software installation and setup. Additionally, users can access our video tutorials and other technical hands-on know-how through the Mech-Mind documentation platform and the Mech-Mind online community.

Download Mech-MSR now to revolutionize your inspection process.

Mech-Mind documentation

Mech-Mind online community

In addition to our extensive online resources, the Mech-Mind team also provides on-site or remote support for global clients, ensuring on-time project delivery.

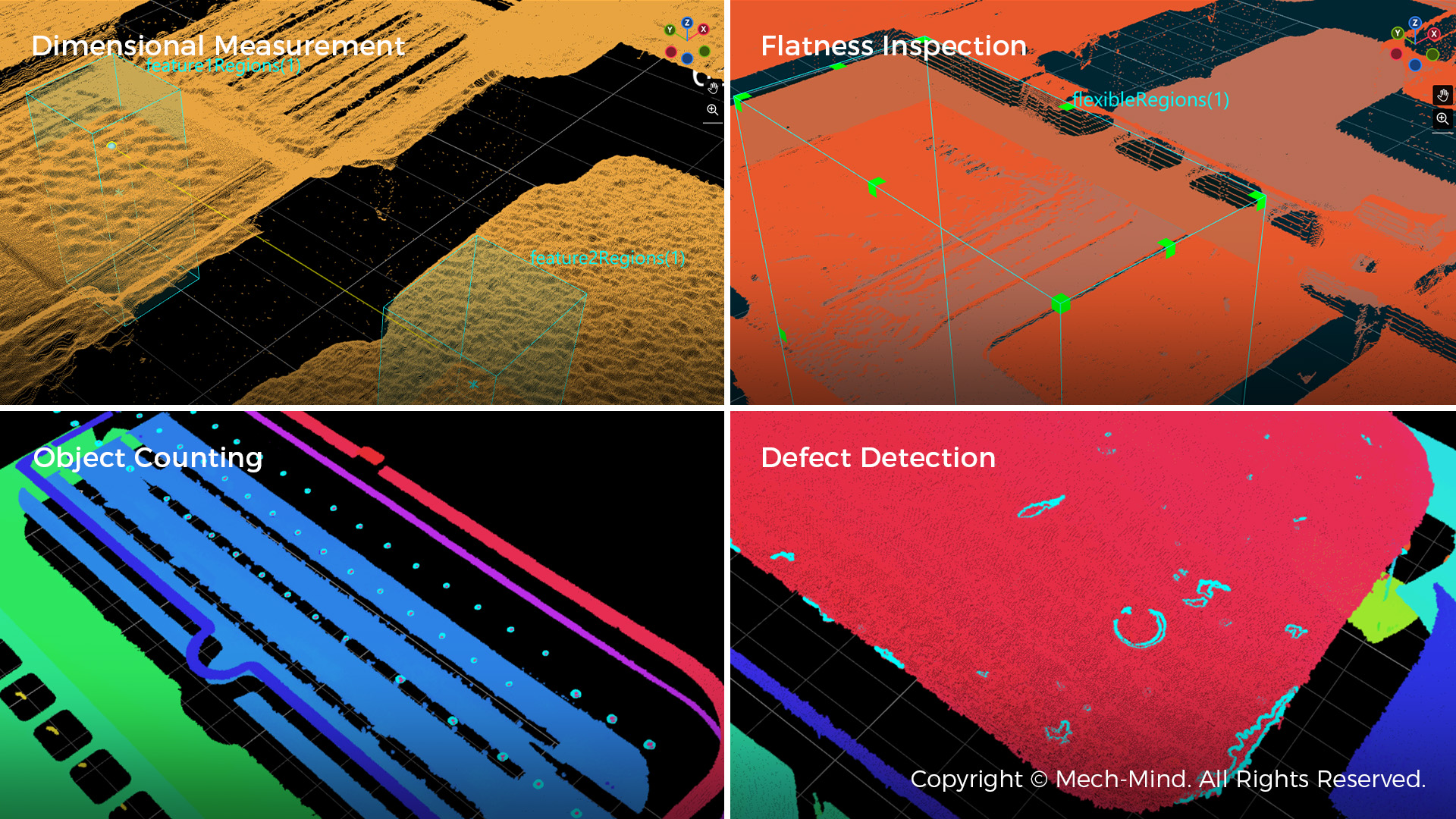

Master a Variety of Inspection Tasks

Mech-MSR's comprehensive suite of robust measurement algorithms empowers it to adeptly handle a wide range of inspection scenarios, including:

• Object counting: Count objects in the production line, adapting to different sizes and shapes.

• Defect detection: Detect common surface defects, such as dents and protrusions, based on depth images.

• Hole locating: Locate target holes and measure their diameters.

• Dimensional measurement: Measure the lengths, angles, and geometrical properties of targets, effectively handling reflective surfaces.

• Flatness inspection: Acquire points on the surface to check whether all the points lie in the same plane.

• Height measurement: Measure the distance between an object's base and its highest vertical point, accurately detecting even tiny height differences.

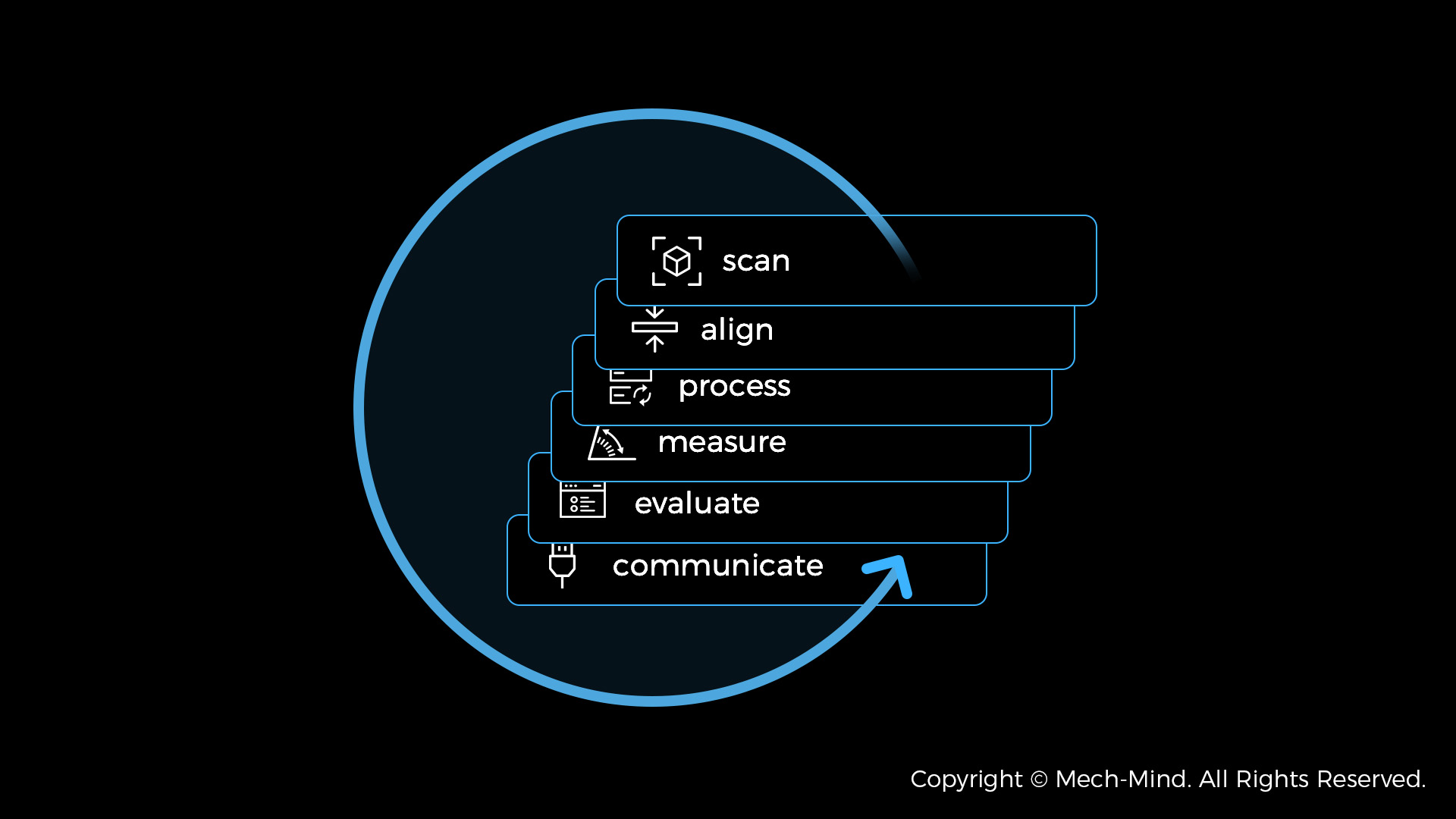

Mech-MSR encompasses scanning, alignment, processing, measurement, data evaluation, and factory communication for creating end-to-end 3D inspection applications.

With Mech-MSR, you can:

• Scan: Easily connect to and run on the Mech-Eye LNX 3D sensors for rapid setup and real-time data collection.

• Align: Quickly align objects and ensure all targets are at the reference position for accurate and efficient measurements.

• Process: Preprocess and optimize depth images, 3D data, and other image data to generate extremely high-quality point clouds.

• Measure: Utilize robust measurement algorithms to perform complex 3D inspection applications.

• Evaluate: Use single-index or comprehensive evaluation methods to meet diverse product quality standards.

• Communicate: Connect PLCs and factory devices using ASCII for real-time data transmission.

02 Application Scenarios

Application 1: Connector Pin Height Measurement

Challenges:

The height consistency of connector pins is crucial for circuit stability and reliable signal transmission. Connector pins are tiny, reflective, and sometimes curled, requiring measurement systems with high precision and stability.

The Mech-Mind solution:

• With ultra-high X-axis resolution and Z-axis repeatability, the Mech-Eye LNX series generates precise and detailed 3D point cloud data for structurally precise and fine-tipped connector pins.

• The advanced algorithms and AI-powered tools precisely measure the height of the pins and separate the curved point clouds.

• Mech-MSR comes with built-in project templates for pin measurements, allowing quick completion of inspection project setup. After Mech-Eye LNX captures 3D point clouds, the Mech-MSR measures the height of the pins to the reference plane and generates the measurement results in real time.

Performance:

• Repeatability measurement accuracy<0.01mm

• Vision cycle time<0.8s

Application 2: Smartphone Midplate Flatness Measurement

Challenges:

The flatness of smartphone midplates is crucial for final assembly. However, midplate structures are precise and exhibit significant variations in color, material, and reflectivity. Consequently, assembly lines require high measurement accuracy and short cycle times.

The Mech-Mind solution:

• The Mech-Eye LNX series features ultra-high resolution and scan rates, perfectly meeting the accuracy and cycle time requirements of assembly lines.

• The single-shot HDR function ensures stable imaging of complex midplate materials.

• Mech-MSR incorporates advanced 3D measurement algorithms, performing plane fitting and flatness measurement using data from two regions, resulting in more accurate measurements.

Performance:

• Repeatability measurement accuracy<0.015mm

• Vision cycle time<0.5s

Mech-MSR offers a user-friendly interface, powerful algorithms, and comprehensive technical guidance, enabling partners to efficiently deploy various measurement and inspection applications. Meanwhile, Mech-Mind has upgraded the performance and specifications of the Mech-Eye LNX series products to better cater to different scenarios in terms of field of view, accuracy, and cycle times. This empowers clients in industries such as consumer electronics, EV batteries, automotive, and photovoltaics to improve product quality and overall production efficiency.

For more information:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net