In the realm of 3D scanning, certain materials pose unique challenges that demand innovative solutions. Reflective surfaces, such as mirror-like, polished metals, and dark materials, like black plastics, often thwart conventional scanning methods. Let's delve into the complexities of these obstacles and explore Mech-Mind's pioneering approaches to overcoming them.

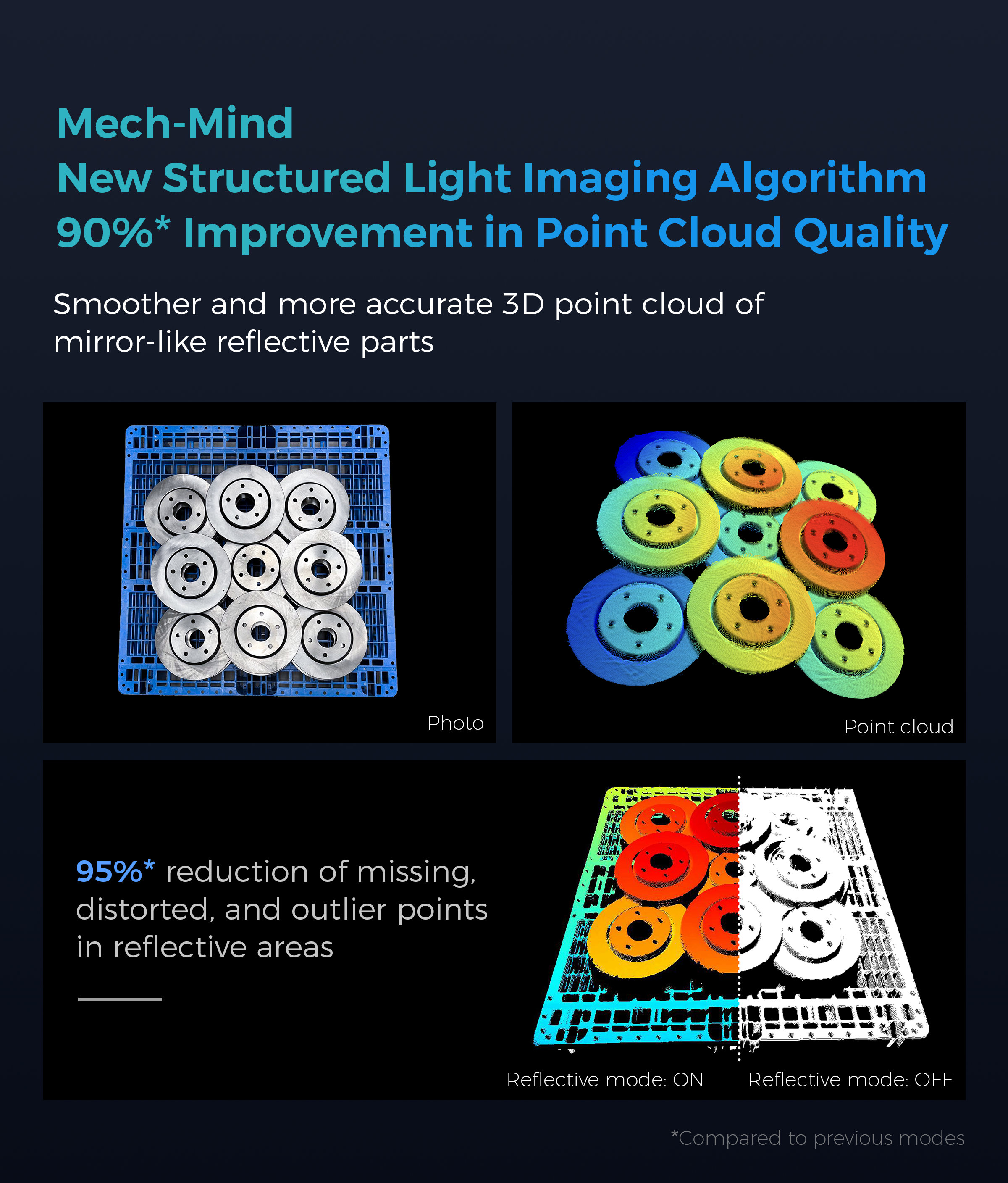

The Shiny Surface Struggle:

Think about trying to scan a shiny metal surface. The laser beam bounces off it, messing up the data and giving us inaccurate results. This results in difficulty for the scanner to accurately capture the object's appearance.

The Mech-Mind Approach:

Mech-Mind has developed a breakthrough algorithm to tackle this. This cutting-edge algorithm helps our 3D cameras handle shiny surfaces much better. With impressive glare reduction and noise suppression capabilities, our algorithm achieves a remarkable 95% reduction in missing or distorted points. This empowers industrial robots to handle shiny stuff without breaking a sweat.

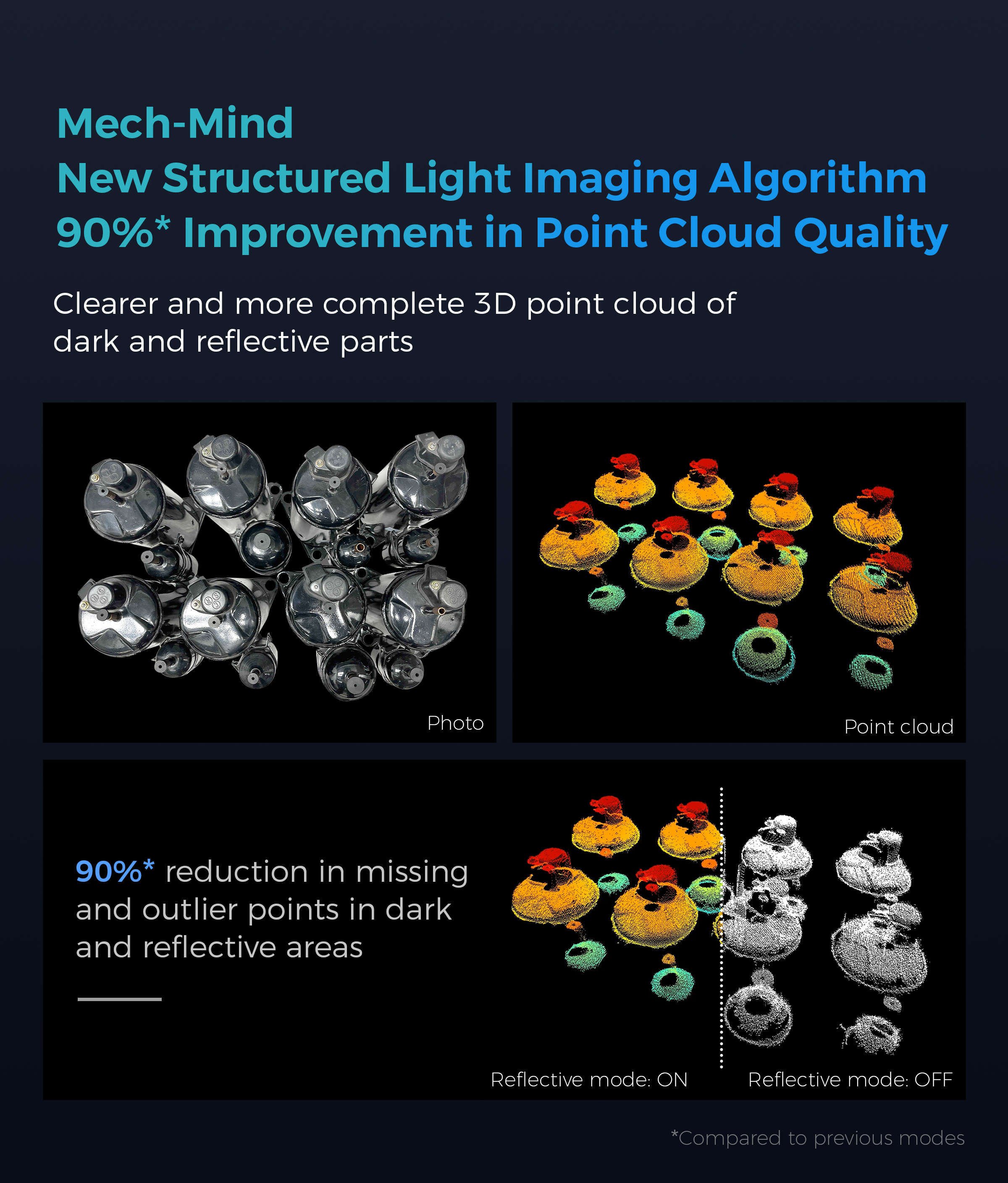

Addressing Dark Materials:

Dark surfaces pose another set of challenges. Not only do they absorb a significant portion of laser light, but they also exhibit poor reflection, resulting in lost structural information. Traditional methods, such as illuminating the surface with artificial light, often fail to produce satisfactory results, resulting in further data loss.

The Mech-Mind Approach:

To counteract these issues, Mech-Mind has developed an innovative 3D vision solution. Mech-Mind's new structured light imaging algorithm leverages high dynamic range imaging capabilities to address these challenges. This innovative approach ensures that sufficient valid signals are captured for both dark and shiny reflective surfaces. By effectively suppressing noise, enhancing contrast, and enabling balanced capture of rich detail levels across both dark and reflective areas, our algorithm reduces point cloud loss and outliers by 90% in dark and bright areas.

Conclusion:

Although the accuracy of 3D sensors can be affected by certain colors and materials due to inherent limitations in scanning technology, Mech-Mind offers versatile AI and 3D vision tools to help achieve desired results.

Our new structured light imaging algorithm, integrated into SDK 2.3, provides enhanced capabilities for handling reflective and dark materials. To explore how our 3D vision technology can benefit your project, contact us at info@mech-mind.net. We're here to offer support and guidance tailored to your specific application needs.