What is bin picking?

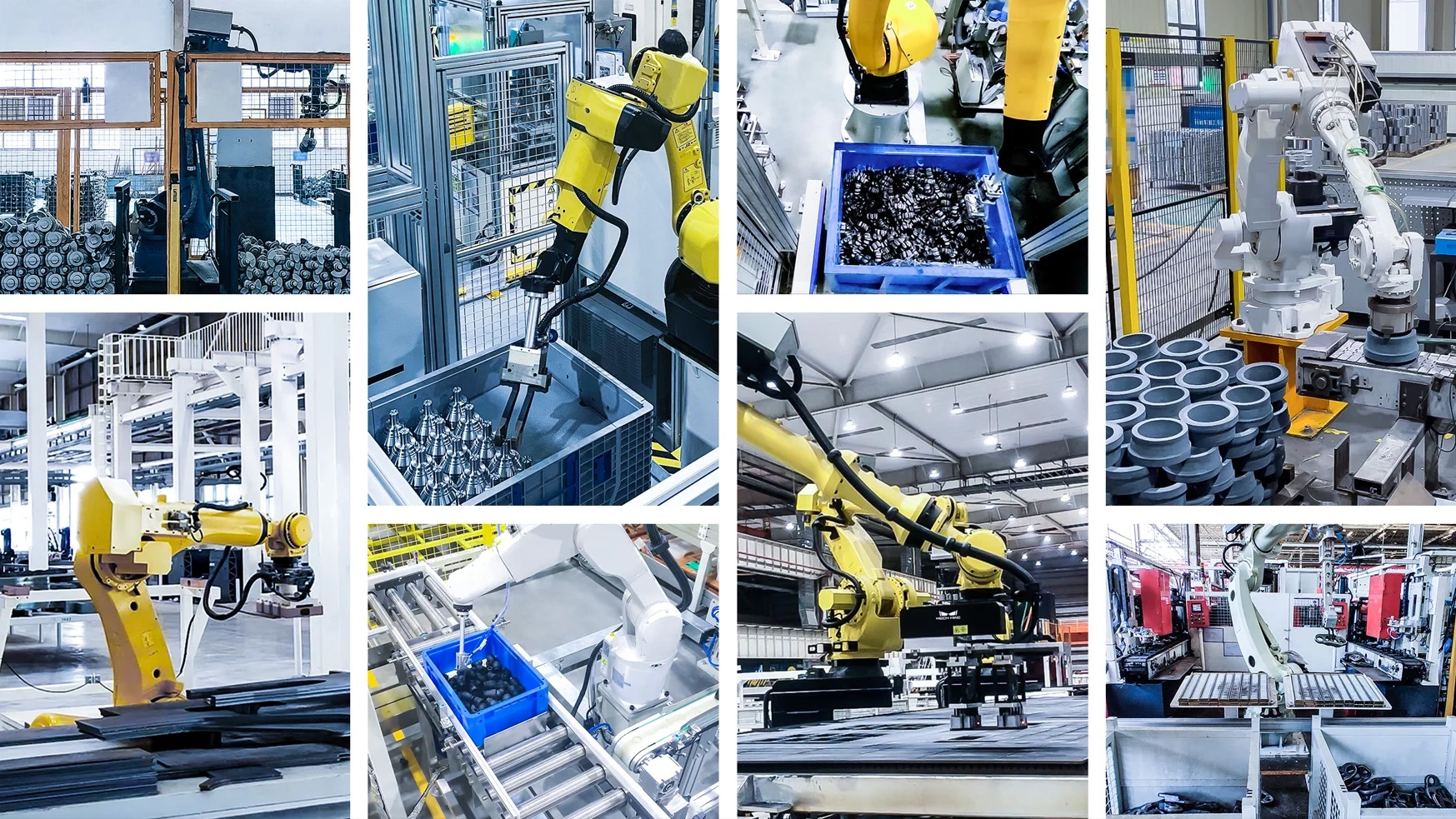

Bin picking is an application based mainly on two technologies: robotics and computer vision. The union of these two technologies makes it possible to extract parts from a container that are arranged in a chaotic manner. The pieces are extracted automatically by a robotic arm which receives orders based on the analysis carried out by the computer vision system. The vision system analyzes the scene and recognizes the positions of the pieces. In addition, it determines which part is the most suitable to extract in each iteration, thus optimizing the entire process. The position of the pieces is established in a 3D space, so the robotic arm is able to pick them up in any position.

The bin picking process requires the following steps:

①Recognize and locate the parts within the container. It is necessary to know their position and orientation.

②It must recognize the distance the container is to position and calculate its trajectories in 3D space.

③Optimize the extraction path.

④Avoid obstacles in the environment during their movements.

⑤Remove the object or part properly without damage.

⑥Position the object or piece at its destination.

All these tasks are carried out autonomously and in reduced cycle times.

Bin picking also allows you to manipulate pieces or more heterogeneous material that until now were done manually. This allows automation of other types of tasks. In addition to the vision system, the mechanical part is important since it is necessary to adapt the end effector or gripper to the type of parts to be extracted and the extraction paths must be optimized to optimize the process as much as possible. In short, bin picking allows us to reliably recognize and extract parts, regardless of their geometry or material.

Bin picking vs. traditional pick and place

The traditional pick and place is based on 2D vision instead of using 3D vision, the robot bases its movements on previously fixed trajectories. It is necessary to program the paths that will be repeated by the robot during the operation. The pieces cannot be positioned and oriented randomly since the robot will carry out the operations for which it is programmed, that is, place from the first to the nth piece from one position to another.

In contrast, bin picking is a complex process in which randomly placed parts must be removed from a container without disturbing the environment. For this, 3D vision is used that allows picking of parts in any position and orientation. The robot will adjust its position and trajectory to extract and place the part in its new position and with the correct orientation.

Benefits of using high-quality 3D cameras in bin picking

Powerful 3D Vision Algorithms:

Guided along by our powerful 3D vision system, the industrial robots can recognize randomly-piled materials, even those with dark or reflective surfaces and complex structures, and then pick them up from deep bins accurately without damaging the components. Capable of accurately identifying and then carefully extracting parts that may be prone to binding up removes the need for human intervention.

Greater Flexibility:

Aiming to enhance efficiency while reducing errors in production, Mech-Mind enables the bin-picking robots to avoid collisions while moving through an active work environment by utilizing cutting-edge path planning algorithms. This reduces the risk of damaging both your components and the machines themselves, preventing costly downtime and material waste. The added flexibility of our robust computer vision and path planning algorithm allows for more seamless production as well, quickly moving even heavy parts with the precision that traditional methods struggle to produce.

Lower Operation Costs and Higher Productivity:

Intelligent bin picking is vastly superior in regard to consistency and efficiency. They are able to work 24 hours a day for months at a time and operate safely and without interruption or any requirement for human interaction. Ultimately, this allows you and your team to realize a substantial boost in productivity while also drastically reducing labor costs.

Conclusion

Higher productivity and lower operating costs are always the pursuits of every manufacturer, and 3D Camera in Robotic Bin Picking has already been widely adopted throughout the industry, with proven results. Through our expertise in the field, Mech-Mind Robotics has and will continue to pioneer 3D camera and deep learning technology. Take advantage of our constant dedication to innovating robust and efficient intelligent robot solutions. For more consultation, please contact Mech-Mind experts.