In recent years, the food and beverage (F&B) industry has undergone a profound transformation fueled by the surge of e-commerce and shifting consumer behavior. The pandemic accelerated this trend, and by 2027, F&B is expected to become the largest e-commerce category—nearly 21% of all online sales (Source: Statista 2025 Report).

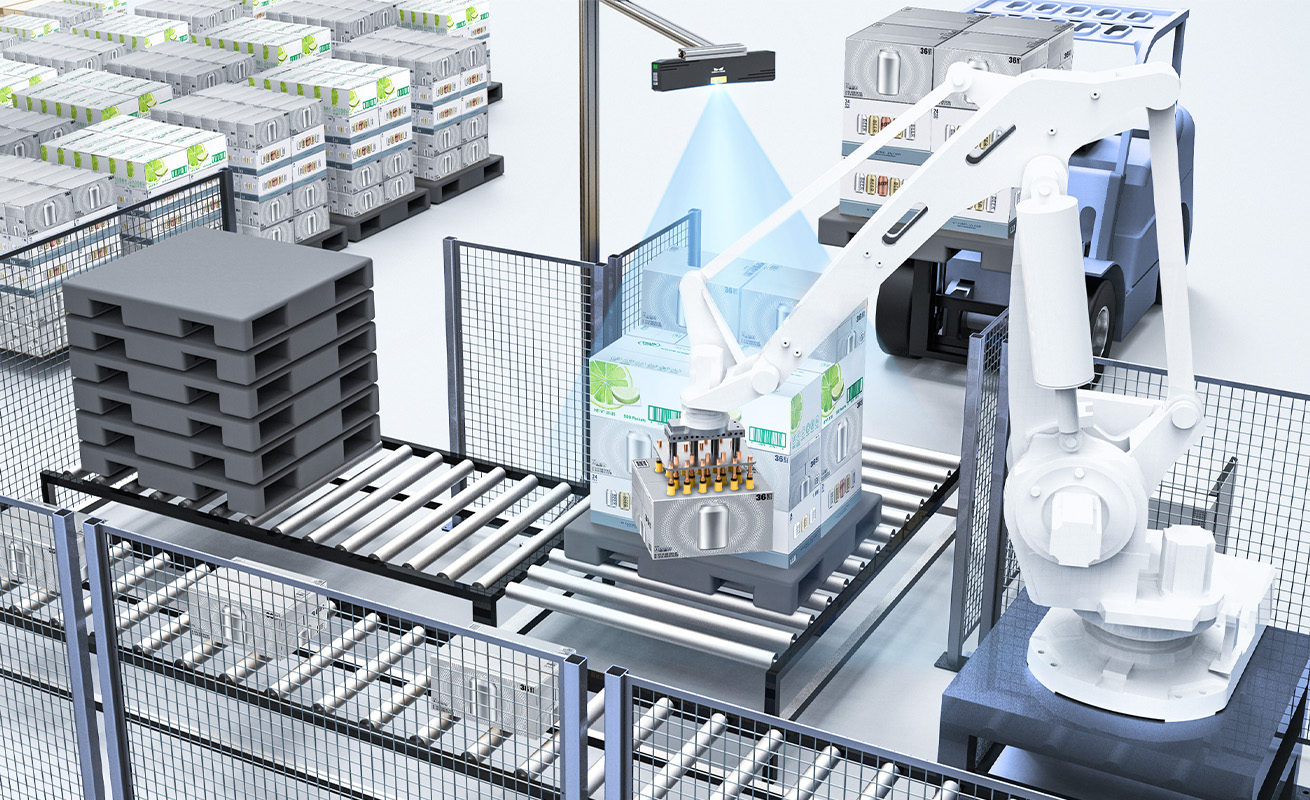

As demand for speed, hygiene, and volume increases, traditional supply chain operations are under enormous pressure to evolve. Automation—particularly AI + 3D Vision-guided robotic depalletizing—is emerging as the key enabler of this next-generation transformation.

Growing Need for Automated Depalletizing in Food and Beverage

From global fulfillment centers to local grocery distribution centers, industry players recognize the urgent need to streamline logistics. Traditional manual depalletizing and legacy 2D machine vision systems are increasingly insufficient to meet the speed, precision, and SKU diversity required in modern F&B operations.

The increased reliance on online grocery shopping brings new challenges to warehouse operations. Fulfillment centers must now process thousands of orders with faster turnaround, narrower error margins, and greater SKU variability—all while maintaining strict hygiene and safety standards. AI-guided 3D vision depalletizing provides an efficient, scalable, and reliable solution.

Addressing the Depalletizing Challenges in Food and Beverage

Depalletizing in the F&B industry involves far more than simply lifting boxes. It must handle several complex challenges:

1. Product Diversity

Pallets often carry mixed SKUs—from fragile produce to shrink-wrapped beverage bottles. These items are difficult for conventional robotic systems to recognize and handle consistently. Advanced 3D scanners and 3D cameras help robot vision systems accurately perceive and handle mixed loads.

2. Storage Complexity

Different products require distinct storage and handling conditions. Items like organic greens, bulk grains, and bottled juices demand specialized depalletizing approaches. 3D vision systems capture shape and volume information to guide tailored pick-and-place strategies.

3. Demand for Speed and Precision

From source to shelf, every stage of the F&B supply chain must operate at high velocity without compromising accuracy. Robotic systems with integrated 3D vision cameras process incoming goods quickly, minimizing damage risk, and maintaining a high success rate—all in real-time.

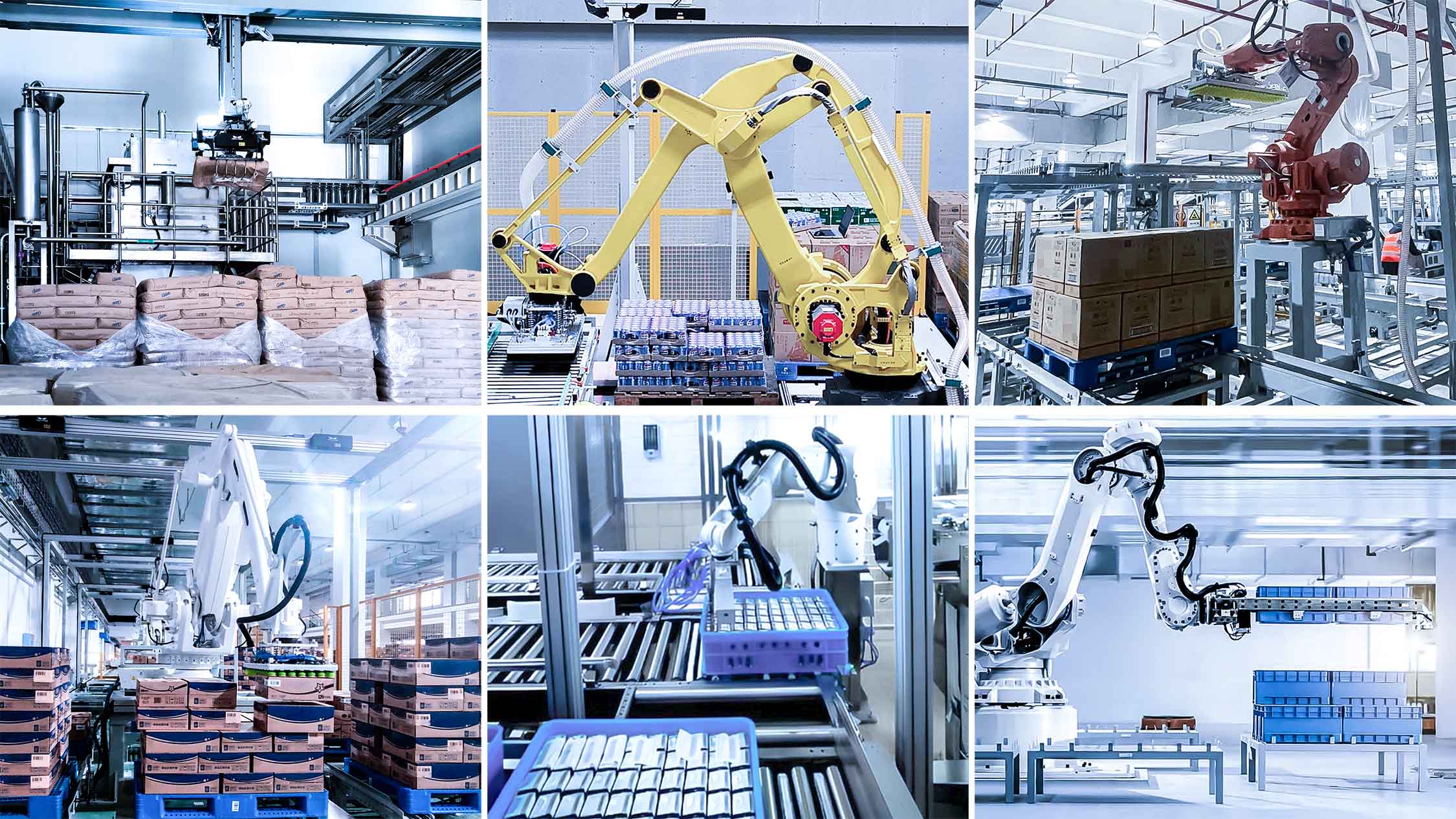

For years, human workers managed these complexities with intuitive judgment. However, repetitive motion, heavy lifting, and constant decision-making lead to fatigue, injury, and inefficiencies. Traditional robotic depalletizers, while helpful, often fall short when confronted with complex-patterned, highly reflective, or shrink-wrapped goods. Such limitations in high-throughput environments cause bottlenecks—delaying picking, sorting, and delivery. With online grocery orders rising, the need for dependable and intelligent depalletizing has never been greater.

Integrating Automation, AI, and Human Oversight

In the rapidly evolving F&B industry, the integration of automation, AI, and human oversight is imperative. As consumer demands shift and supply chains become more complex, businesses must adopt a holistic solution that leverages the strengths of each component to stay competitive.

1. Automation

Serves as the backbone of modern depalletizing operations, automation handles repetitive and physically demanding tasks with speed and precision. Pick and place robots equipped with 3D vision cameras can operate continuously, reducing the risk of workplace injuries and ensuring consistent throughput. This mechanization reduces labor costs and boosts efficiency, enabling human teams to focus on strategic roles.

2. Artificial Intelligence

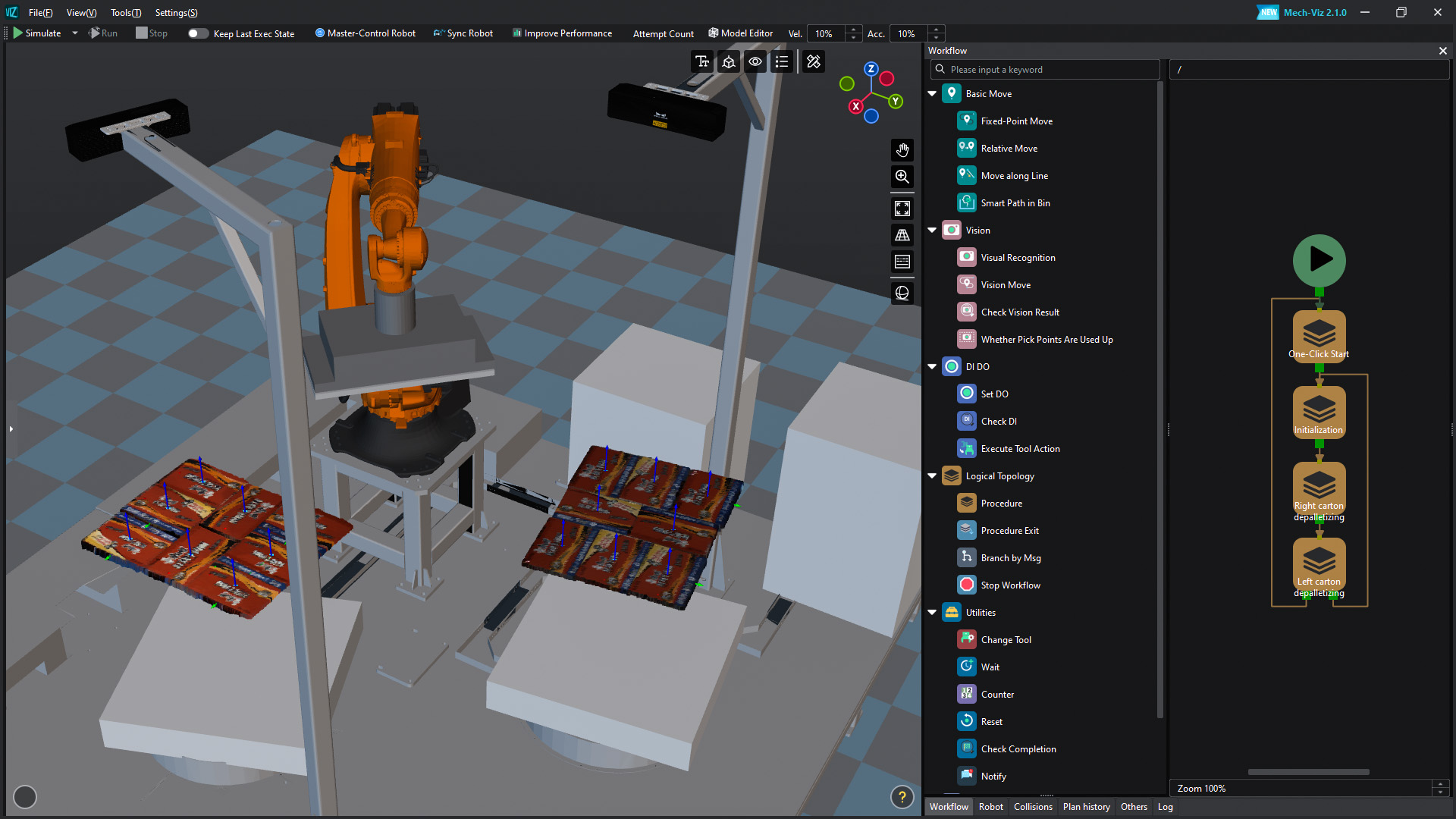

Combined with 3D vision technologies, artificial intelligence can generate optimal depalletizing strategies by enabling systems to “see” and “think”. AI-guided 3D vision depalletizers can adapt to various challenging tasks. This flexibility is crucial in the F&B industry, where product diversity is vast and constantly changing.

3. Human Oversight

As a critical component, human oversight ensures automated systems function optimally and adapt to unforeseen challenges. Workers transition into supervisory roles, monitoring system performance, managing exceptions, and providing the nuanced decision-making that machines cannot replicate.

Depalletizing application driven by intelligent algorithms

By harmoniously integrating automation, AI, and human oversight, F&B companies can achieve a depalletizing process that is efficient, adaptable, and aligned with the industry’s dynamic demands.

Mech-Mind’s AI + 3D Vision Depalletizing Solutions

Mech-Mind Robotics, a global leader in AI + 3D Vision, provides proven technologies and practical solutions that empower the F&B industry to modernize depalletizing with efficiency.

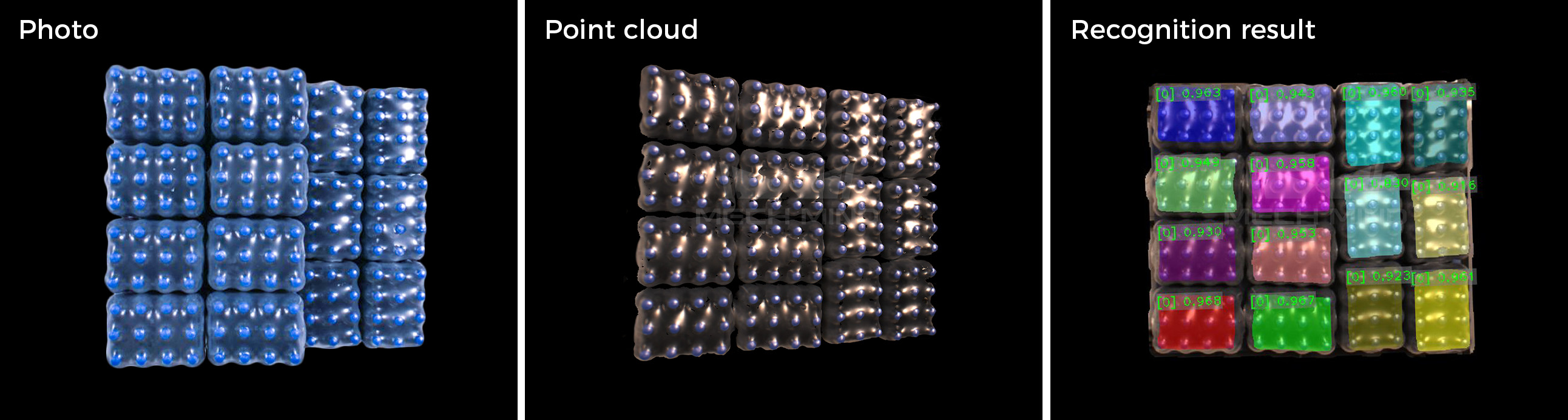

Mech-Eye industrial 3D cameras generate high-quality point clouds and reliable recognition results, enabling accurate 3D imaging of items with challenging features (reflective surfaces, transparent shrink-wraps, complex patterns, etc.). This powerful 3D vision foundation ensures reliable robot operation in diverse scenarios (logistics, warehousing, manufacturing, etc.).

Uneven, transparent shrink-wrapped packaging

To complement the Mech-Eye industrial 3D cameras, Mech-Mind provides robust software tools —Mech-Vision, Mech-Viz, and Mech-DLK. These user-friendly tools enable customers to effortlessly and rapidly deploy complex automation tasks.

In proven depalletizing applications, this advanced 3D vision system—powered by our self-developed AI algorithms—delivers high recognition accuracy (≥ 99.9%), fast cycle times (< 0.5 seconds), and seamless adaptability to diverse SKUs without pre-registration.

By integrating precision hardware and intelligent software, Mech-Mind’s AI-guided 3D vision system processes up to 900 pieces per hour, streamlining depalletizing operations and accelerating return on investment (ROI).

Conclusion: Building a Smarter, More Resilient Supply Chain

As the F&B industry continues to evolve, the integration of automation, AI, and human oversight is becoming essential for operational success. Mech-Mind Robotics is proud to support this shift with proven 3D vision solutions that boost productivity and reduce costs.

By adopting an advanced AI + 3D Vision-guided depalletizing system, F&B retailers and logistics providers can stay competitive, responsive, and aligned with the expectations of consumers.

AI + 3D Vision Applications in Food and Beverage

AI + 3D Vision Applications in Food and Beverage