Picture this: a robot gently picks up your misplaced keys, untangles a knotted phone charger, or even threads a needle—all reliably, safely, and without any special setup. This isn’t a scene from a futuristic movie—it’s the transformative power of dexterous robotic hands, where advanced mechanics, precision sensing, and intelligent software converge to turn “impossible” manual tasks into reality.

The dexterous hand is the missing link in complex tasks: when a robot can grasp, adjust, and manipulate objects with finesse, it becomes useful in homes, retail, healthcare, logistics, and other challenging industries. Recent improvements in materials, actuation, sensing, and control—combined with smarter software and scalable manufacturing—are making these hands increasingly capable, affordable, and dependable.

If you want to know why dexterous hands matter, how the technology reached today’s state, and what developers and integrators should prioritize now, read on. This is the story of embodied intelligence, human-level manipulation, and the path from lab prototype to real-world service-ready system.

Why a Dexterous Hand is the Missing Link in Complex Tasks

Everyday environments are built for human hands—tools, products, devices, and everyday objects all assume human use. In these same settings, a truly dexterous robotic hand enables natural and effective interaction, unlocking capabilities that feel intuitive, reliable, and genuinely useful in both service and consumer applications.

Perception–action unity: Tight integration of sensing and control lets the hand sense contact, adjust grip, and move continuously—so robots don’t just see the world, they respond to it in real time.

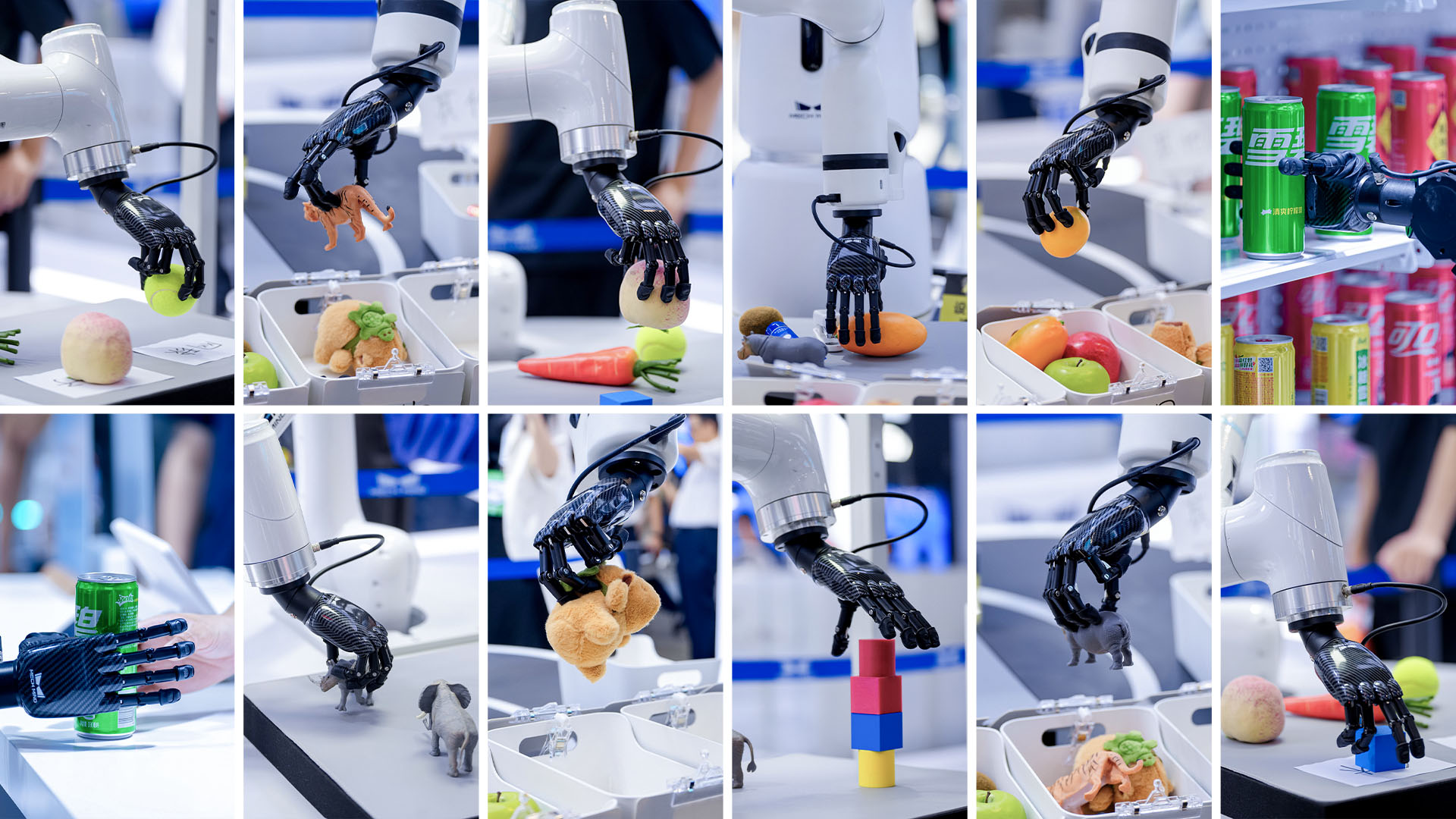

Adaptive in-hand manipulation: The ability to regrasp, shift, and conform to objects enables handling of varied shapes, sizes, and materials without special tooling.

Fine manipulation: Precise force and motion control make delicate tasks reliable—reorienting small parts, inserting connectors, operating buttons or zippers, and using simple tools.

Human-friendly interaction: Compliance and sensitive force control allow safe contact with people and personal belongings, reducing risk and improving trust.

Versatile multi-tasking: One dexterous hand can perform many roles across homes, retail, hospitality, and personal care—fetching, sorting, tidying, merchandising, and more—without constant reconfiguration.

Mech-Hand Five-Finger Dexterous Hand

In short, dexterous hands are the bridge between perception and meaningful action—the essential interface for robots that genuinely assist people in everyday life.

Balancing Performance, Cost & Reliability

The dexterous hand has evolved from an invention into a commercial product. Designers must balance three interdependent priorities—performance, cost, and reliability. High-performance robotic hands often depend on sophisticated mechanisms and dense sensing, which raise both upfront cost and ongoing maintenance. Lower-cost solutions can reduce capability or precision, while industrial-grade reliability typically requires robust materials, redundancy, and extensive validation.

Advances in sensors, software, modular design, and manufacturing are steadily narrowing these gaps. By matching design choices to the target use case and tightly integrating hardware with software, teams can produce hands that deliver strong capability, reasonable cost, and the dependable durability needed for real-world deployments.

Six Technical Pathways: Shaping Dexterous Hand Design

Direct-drive (one motor per joint):

Provides low backlash, high-fidelity position/torque control, and good collision tolerance from backdrivability; drawbacks include lack of self-locking (motors must often stay energized to hold position), higher continuous power/heat and associated wear, which can hurt long-term reliability.

Tendon (cable) drives:

Motors are housed in the forearm or base, producing light, compact fingers with human-like kinematics and low distal inertia that simplify packaging; however, tendon compliance, routing complexity, and friction complicate precise position and force control.

Linkage mechanisms:

Mechanical linkages can map few actuators to many joints. They can be designed for high stiffness and precision or deliberately underactuated to enable adaptive, self-forming grasps. Trade-offs depend on linkage topology and intended behavior.

Gear/worm-gear drives:

Provide high torque density and independent joint control but increase weight, mechanical complexity, and reduce backdrivability — which can hurt safety and force sensing. Worm gears are notable for non-backdrivability/self-locking behavior.

Pneumatic/hydraulic “artificial muscles”:

Offer high force and intrinsic compliance. However, pneumatics’ compressibility and soft actuators’ nonlinearities limit precision and bandwidth, while hydraulics introduce sealing, maintenance, and cleanliness concerns.

Every approach makes different trade-offs in precision, weight, durability, and control. The winning commercial design will be the one that best balances these factors to meet diverse requirements of complex real-world environments.

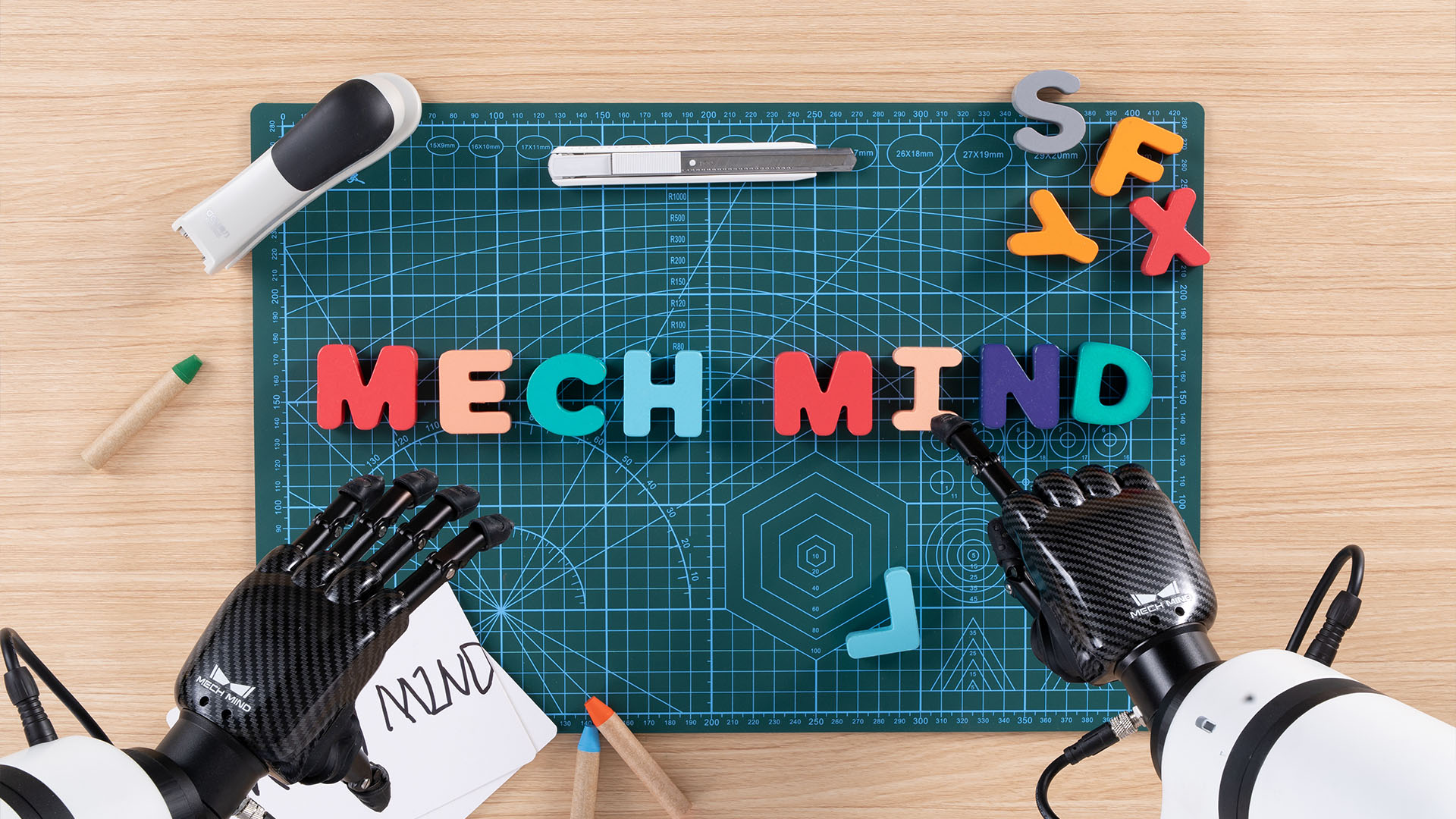

How Mech-Mind Approaches Dexterous Hand Integration

We believe manipulation and perception must go together. A high-performance hand without reliable 3D vision cannot reach its full potential. Mech-Mind integrates industrial 3D cameras (Eye) with AI software suites (Brain) and dexterous end-effectors (Hand), adaptable across different robot platforms. This enables robots to perceive with accuracy, reason intelligently, and execute tasks efficiently—even in complex, unpredictable environments.

Mech-Eye (3D vision)—Equipped with advanced AI imaging algorithms, the industrial 3D cameras can capture high-quality 3D data of transparent and reflective objects. Moreover, we offer a variety of Mech-Eye models that are well-suited to the needs of diverse scenarios

Mech-GPT (AI software)—The multimodal large model empowers robots with human-like learning, understanding, and reasoning abilities. Robots can understand linguistic instructions, perceive complex environments, and autonomously perform tasks.

Mech-Hand (dexterous hand)—The five-finger dexterous hand features a compact design, high flexibility and strong stability. Integrated with a generalizable AI grasping algorithm, it can efficiently and precisely grasp a wide variety of objects.

Where the “Eye-Brain-Hand” technology stack delivers value:

Rapid task generalization: The “Eye” recognizes objects and environments, the “Brain” composes or selects a manipulation policy, and the "Hand" executes it—enabling fast re-tasking across homes, retail, and service sites without hardware changes.

Vision-guided precision: Continuous depth and pose feedback from the “Eye” lets the "Brain" correct trajectories in real time, so the “Hand” can perform delicate alignments, insertions, and tool use with repeatable accuracy.

Robust handling of variability: When the “Eye” detects uncertainty (occlusion, deformable shapes, novel items), the "Brain" chooses adaptive strategies (regrasp, compliant approach), and the “Hand” implements them—turning visual ambiguity into reliable physical outcomes.

Scalable service & home applications: One platform, multiple scenarios — safe, versatile manipulation that extends from factory workflows to real-world home assistance.

The Mech-Mind “Eye-Brain-Hand” technology stack gives developers and integrators a practical, repeatable path from research to real-world service applications, delivering dependable manipulation for both service and consumer use.

The Future of Dexterous Hands

Imagine a typical home in 2030: a robot picks up an unfamiliar household item, adjusts it in-hand, uses a simple tool, completes the task, and settles into a new grip. That's the promise of dexterous hands combined with 3D vision and AI brains. This transformation is already underway.

Teams that design dexterous hands alongside perception and decision systems will unlock broader, more reliable behaviors. Treating the hand as a central system component—not an afterthought—will help capture the next decade of real-world flexibility and usefulness.