In today’s rapidly evolving automation landscape, choosing a 3D vision system is no longer just a technical decision—it is a long-term investment in reliability, scalability, and production stability. From automotive and electronics to logistics, food & beverage, and metal & machining, system integrators face the same fundamental challenge: building robotic systems that work not only in the lab, but also consistently on the factory floor.

This is where Mech-Mind stands out. Across industries and applications, integrators and end users choose Mech-Mind for one reason above all: trust in its performance, its reliability, and its integrated "Embodied AI + 3D Vision" stack built for real-world deployment.

Industrial-Grade Reliability and Consistent Performance

A 3D camera can look impressive during initial testing. However, true reliability is revealed months or even years after deployment. In the field, temperature fluctuations, vibrations, dust, ambient light interference, and continuous operation can cause 3D cameras to drift out of calibration, degrade in accuracy, or even stop working. Over time, these issues lead to more breakdowns, unplanned downtime, and higher labor costs for maintenance and troubleshooting.

Mech-Eye Industrial 3D Cameras are engineered specifically for these conditions. Featuring rugged aluminum alloy housings, IP65/IP67 protection, and certified compliance with international industrial standards, Mech-Eye 3D cameras are designed to operate reliably in demanding environments. Their certified MTBF of up to 100,000 hours means you will spend far less time on repairs and maintenance. In other words, you can see lower upkeep costs and reduced need for on-site troubleshooting.

To address long-term accuracy challenges, Mech-Mind provides built-in auto-correction tools for vision-system drift. These tools continuously monitor accuracy and compensate for drift caused by temperature changes or component aging, helping ensure stable picking and measurement performance over time.

Proven in real-world cases:

"The system accurately detects red-hot railway wheels, provides reliable 3D point clouds even under harsh lighting and high-temperature conditions, computes collision-free grasping paths, and guides robots to perform safe, repeatable machine tending with precision and efficiency." — A Leading Steel Group

Complete, High-Quality 3D Point Clouds—Even on Challenging Objects

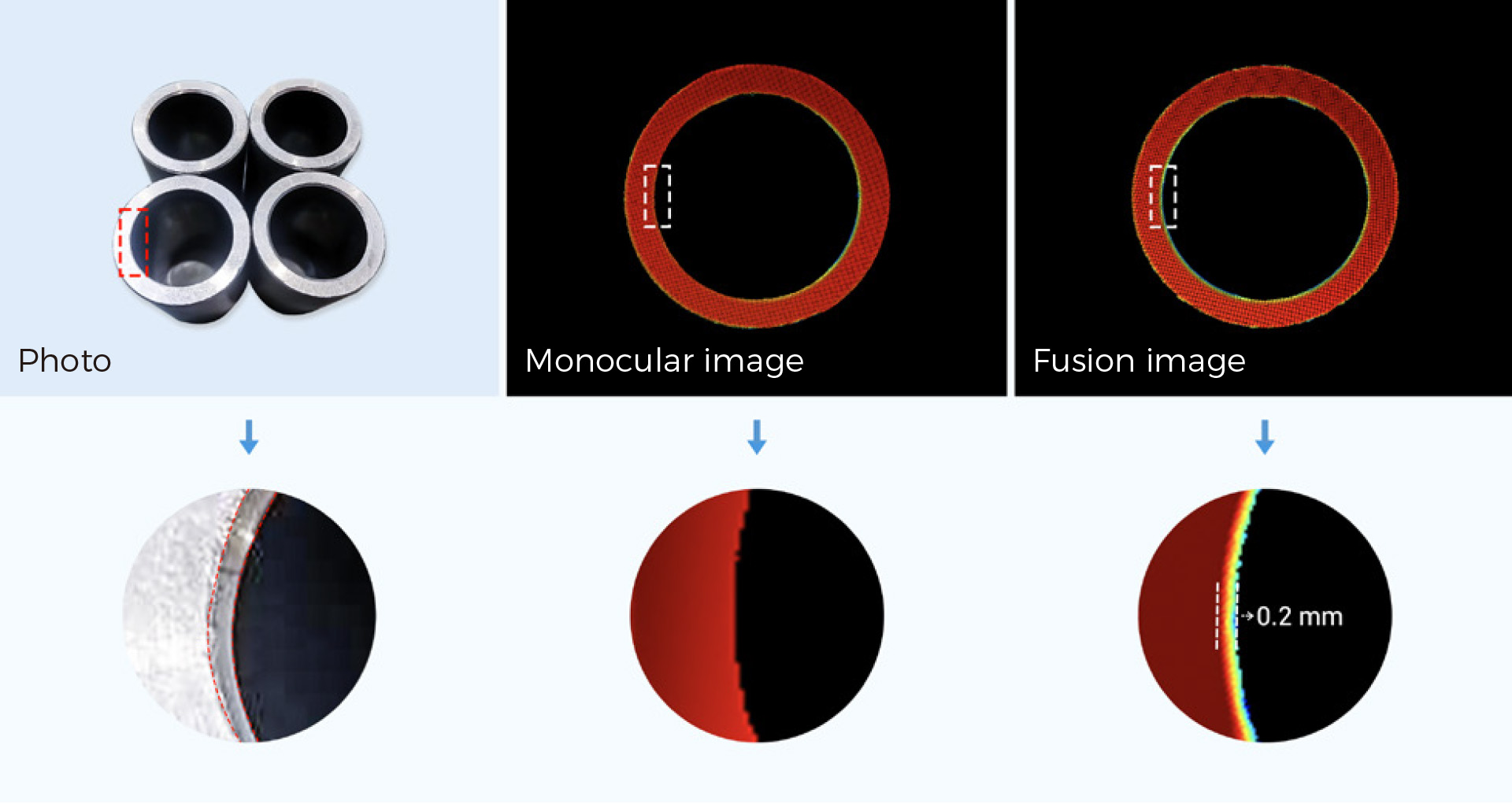

Accuracy alone is not enough. In real production environments, robots must handle dark, reflective, transparent, or complex-shaped objects—conditions that can produce incomplete or noisy point clouds. These gaps and errors in the data lead to failed grasps or unstable operations.

Mech-Eye 3D cameras are designed to capture dense, detailed, and complete 3D point clouds, even under strong ambient light or on shiny, reflective surfaces. Advanced optical design, fast structured-light scanning (with HDR imaging), and robust anti-reflection algorithms work together to reduce noise, minimize blind spots, and preserve fine surface details.

The result is reliable object recognition and pose estimation in scenarios such as random bin picking, tightly packed depalletizing, and inspection of metallic or glossy parts, without sacrificing robustness.

Proven in real-world cases:

"Mech-Eye generates high-quality 3D point clouds of randomly piled parcels (boxes, pouches, envelopes, etc.), enabling accurate picking and fast adaptation to new parcel types—even when packages are glossy, deformed, or partially occluded." — A Large Distribution Center

High Accuracy — Correct Representation of Reality

In robotic applications such as picking, assembly, inspection, and inline measurement, accuracy is non-negotiable. Even small deviations in 3D data can lead to misalignment, failed grasps, or incorrect measurements. Conventional vision systems often require human intervention or manual processes to meet these tight tolerances, adding cost and slowing production.

Mech-Mind’s Mech-Eye 3D cameras deliver high-accuracy, true-to-scale 3D data, verified to international standards such as VDI/VDE 2634. Whether at short, medium, or long working distances, Mech-Eye provides precise depth, position, and orientation data, enabling robots to interact with the physical world with confidence.

This accuracy directly translates into higher success rates in demanding applications, from precision component handling to large-scale inline measurement of automotive parts.

Proven in real-world cases:

"The vision-guided robot precisely measures the key parameters of each assembly feature on the subframe (diameter, position, flatness, etc.), ensuring subframes can be properly and securely joined together." — A Large Automotive OEM

Speed and Throughput Optimization

In high-volume production, throughput directly drives ROI. However, many vision systems slow down when capturing high-quality data: higher speeds often mean worse, lower-fidelity scans. Integrators face a trade-off between speed and reliability, which can become a bottleneck.

Mech-Eye’s imaging pipelines are engineered to break that trade-off. Typical capture times on production models can be in the sub-second range while preserving full 3D point cloud fidelity, allowing robots to raise pick rates and shorten cycle times without sacrificing accuracy or robustness.

As a result, you can see the measurable gains in high-speed picking, depalletizing, and other production-line tasks, where every second counts.

From Vision to Action: the General-Purpose "Eye-Brain-Hand" for Robots

One of Mech-Mind’s defining strengths is that it goes beyond standalone hardware. Instead of treating 3D vision, AI, and robot control as separate components, Mech-Mind offers a standardized, end-to-end "Eye-Brain-Hand" robotics portfolio.

This unified approach allows you to move faster from concept to production, while maintaining flexibility across robot brands, application types, and industries.

Fast Deployment and Easy Integration

For system integrators and developers, how quickly a 3D vision system gets up and running often decides whether a project hits its deadline. Tight schedules, complex workflows, growing functional demands, and limited engineering resources mean every minute spent on manual calibration, custom scripting, or assembling toolchains is wasted time — and money.

Mech-Mind’s "Eye + Brain" system is built to wipe that slate clean. It combines industrial-grade 3D sensing with no-code/low-code vision tools, one-click simulation, a library of ready-to-use solution templates, and multi-language SDKs—giving teams a fully production-ready system. Pre-calibration profiles and guided workflows remove the guesswork, allowing you to go from unboxing to dependable operation much faster. And when the inevitable questions arise, Mech-Mind’s engineers step in. Backed by comprehensive documentation, hands-on training, and a global support network, issues are resolved quickly, keeping projects on track. With the right tools and a responsive partner, the path to production gets a whole lot smoother.

Proven at Scale, Across Industries Worldwide

Today, Mech-Mind’s "Eye + Brain" systems are deployed in over 40 countries, with more than 17,000 cameras installed and adoption by 100+ Fortune Global 500 companies. From automotive and EV battery to logistics, electronics, metal & machining, and food & beverage, Mech-Mind technology is trusted in diverse, high-demand production industries.

These real-world deployments reinforce a simple truth: performance on paper matters, but performance in production matters more.

Conclusion: More Than a 3D Camera—A Partnership

Choosing a 3D vision system is about more than just specifications. It is about selecting a partner that understands industrial reality—one that delivers reliable hardware, powerful (yet user-friendly) software, and long-term support for evolving automation needs.

Mech-Mind’s general-purpose "Eye-Brain-Hand" for robots reflects this philosophy. By combining industrial-grade reliability, accurate and complete 3D data, capture pipelines optimized for throughput, and an integrated software ecosystem, Mech-Mind empowers system integrators to build robotic solutions that perform consistently—not just today, but for years to come.

We meet the technical expectations of leading solutions and deliver the practical production metrics that matter: long-term stability, drift-free accuracy, high throughput, and easy end-to-end deployability. We consistently provide the outcomes our customers and partners value most. In an era of increasingly complex automation challenges, proven experience and support make the difference. That is why so many choose Mech-Mind.

For more information on Mech-Mind's products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net

Mech-Mind Robotics Product Catalog.pdf

Mech-Mind Robotics Product Catalog.pdf