As manufacturers race toward smarter, more autonomous production, machine vision software has become the intelligence layer that converts perception into action. Cameras and sensors may be the eyes of industrial automation—but it is software that gives those eyes meaning, enabling robots and systems to recognize, measure, and decide.

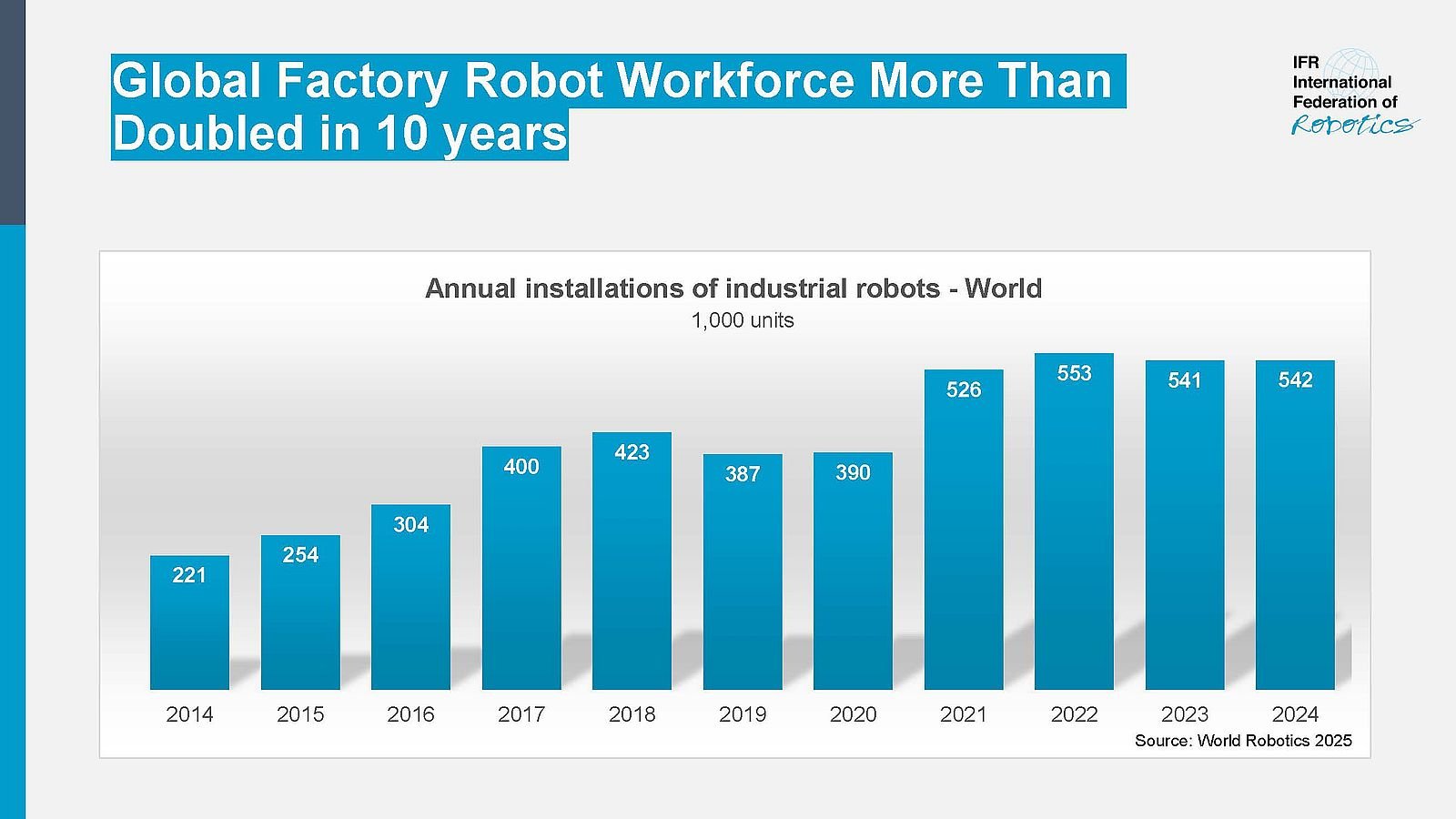

In 2024, global robot installations reached 542,000 units—more than double the figure a decade ago—and the total number of operating robots exceeded 4.66 million worldwide (source: IFR, 2025).

Annual global industrial robot installations, 2014–2024 (Source: IFR, World Robotics 2025)

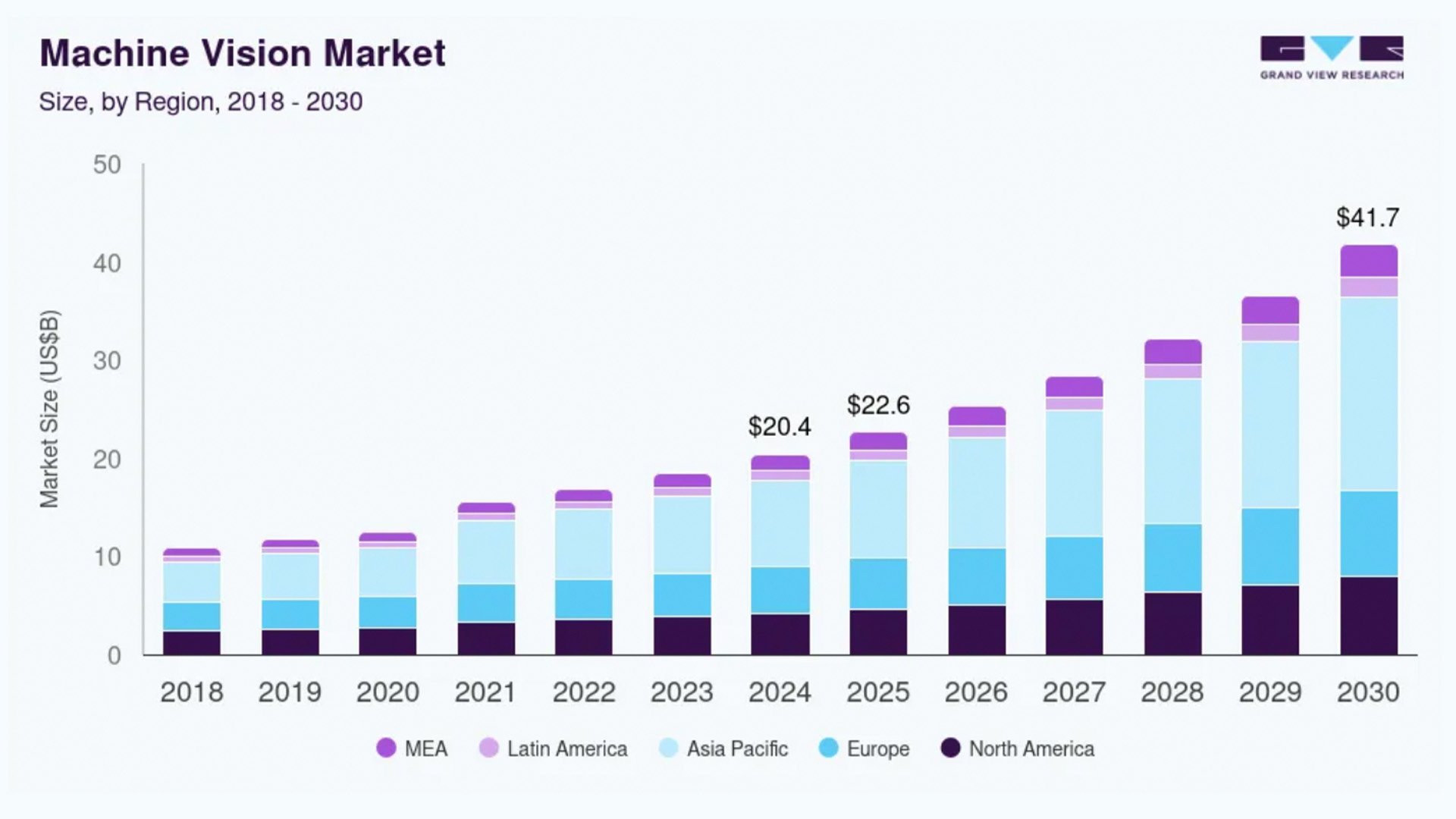

Meanwhile, the machine vision market is growing rapidly. According to Grand View Research, the global machine vision market size was estimated at USD 20.38 billion in 2024, and is projected to reach USD 41.74 billion by 2030, growing at a 13.0 % CAGR over the period.

Global Machine Vision Market Size, 2025 - 2030 (Source: Grand View Research)

Within this broader market, the software segment is expected to expand strongly. In 2024, the software portion was estimated at USD 5.93 billion, with a projected CAGR of 13.8% from 2025 to 2030 (source: Grand View Research, 2025).

These numbers reveal a clear trend: as automation expands, machine vision software is emerging as the true intelligence behind modern manufacturing.

From Algorithms to Intelligence: AI Becomes the Core

A decade ago, machine vision software was rule-based—programmers wrote scripts to define every possible defect or object position. Today, deep learning and AI training pipelines allow machines to learn patterns on their own. Instead of coding thousands of inspection rules, engineers show the software examples of “good” and “bad”, letting neural networks infer what to detect. This transition from explicit programming to active learning has cut setup times from days to minutes in many factories.

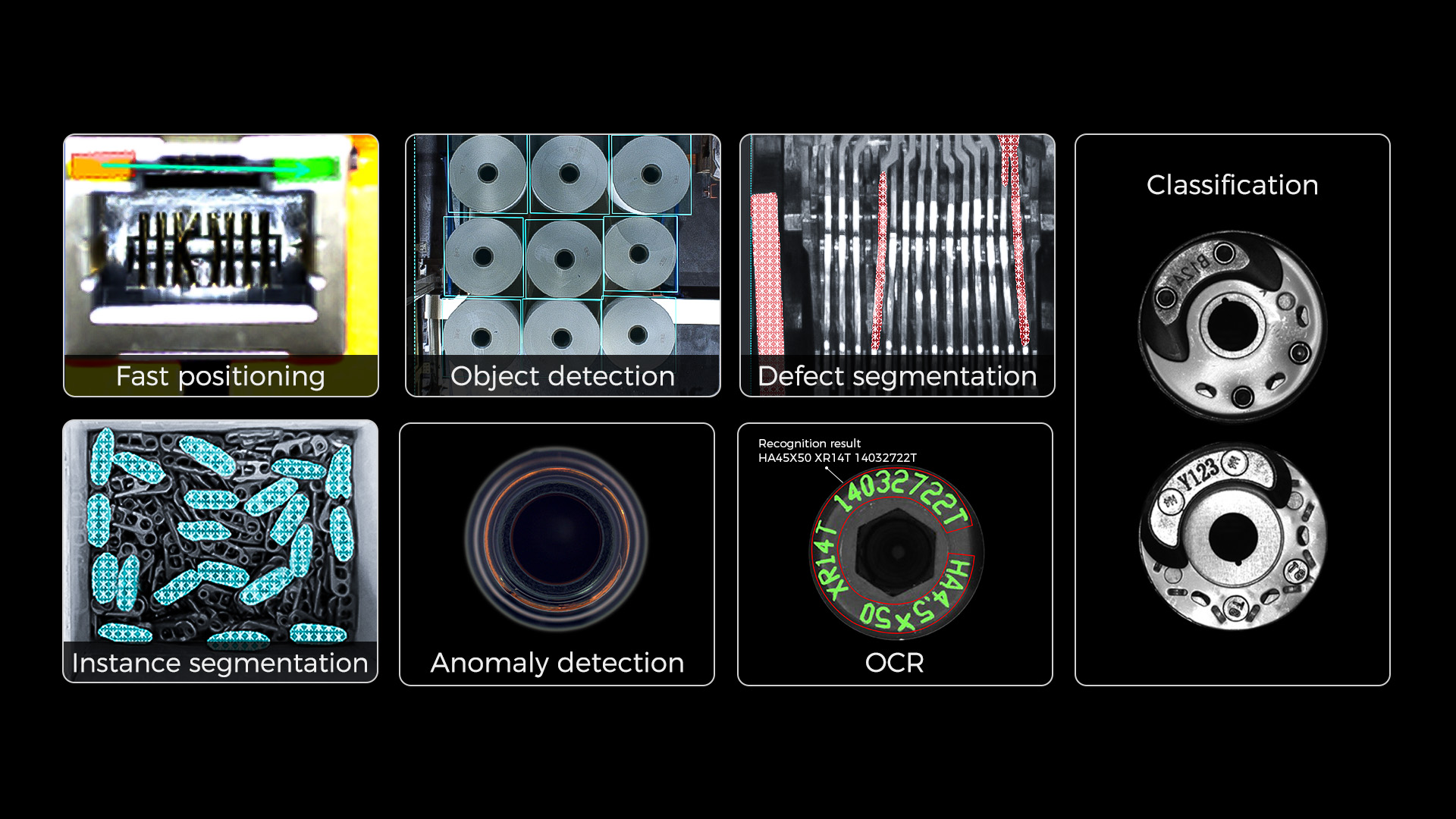

AI-based inspection also broadens what’s possible. In the electronics and EV battery industries, subtle surface defects and variable lighting once confounded traditional algorithms. Deep-learning software like Mech-DLK now handle such complexity with accuracy exceeding 99% while requiring far smaller image sets. Its graphical interface and smart labeling tools make AI adoption feasible even for engineers without coding experience. The trend is clear: machine vision software is becoming a user-driven, continuously learning system.

A robust AI toolkit enables rapid model training for demanding tasks. (Mech-DLK)

From 2D to 3D: Spatial Perception and Understanding

Industrial automation is no longer confined to 2D imaging. The rise of 3D vision brings spatial intelligence into the image—robots can now perceive depth, shape, and orientation. This shift has unlocked applications such as random bin picking, precision assembly, and weld inspection, where 2D images are insufficient.

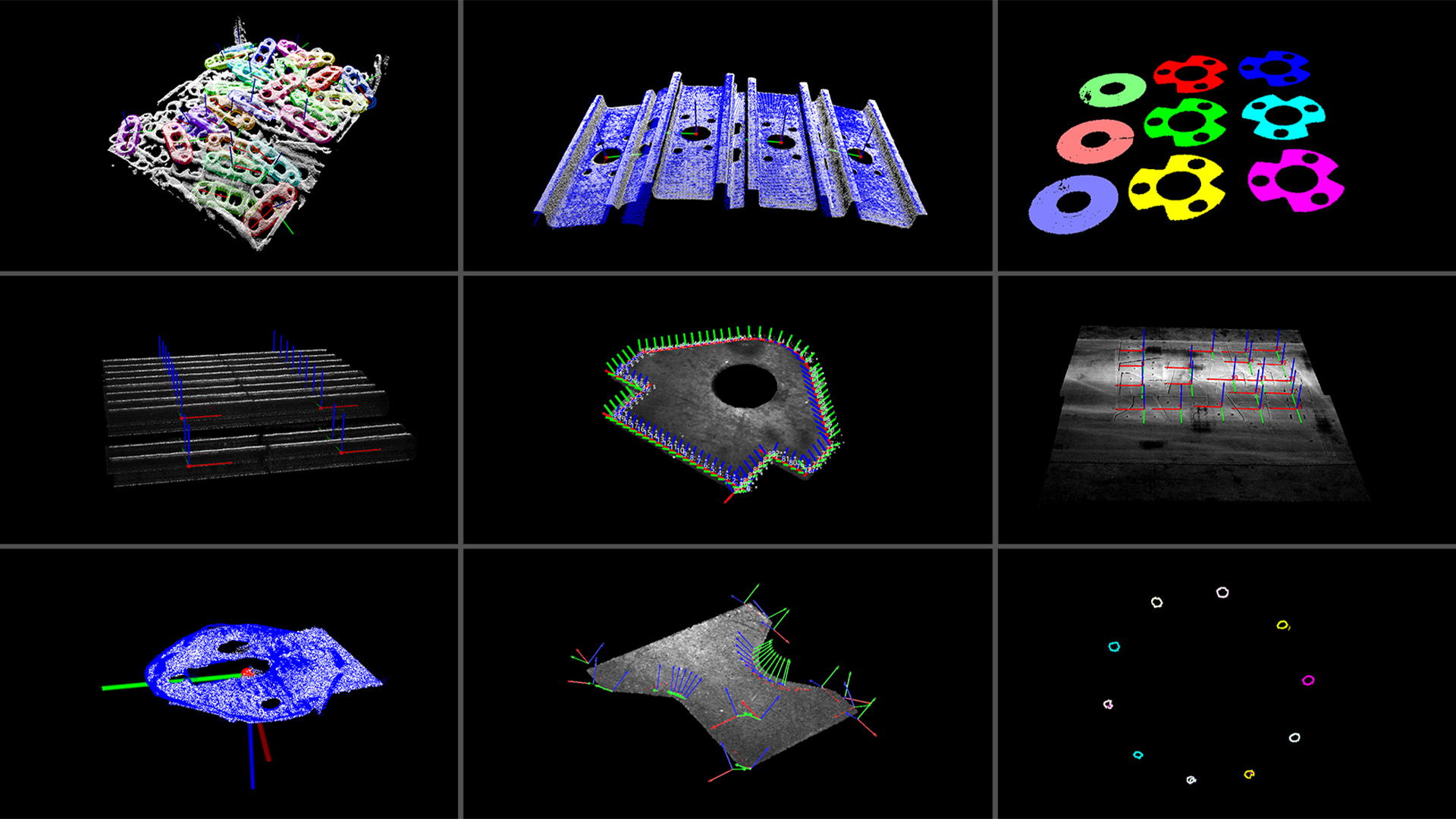

Modern machine vision software must process dense point clouds, fuse data from multiple sensors, and generate precise geometric measurements. Mech-Vision exemplifies this evolution with its built-in algorithms such as 3D matching, pose adjustment, and deep-learning modules. It integrates seamlessly with Mech-Eye Industrial 3D Cameras to locate and recognize parts—even when they are randomly stacked or highly reflective—and to execute high-precision picking tasks. Its no-code interface and ready-to-use templates illustrate how the industry is moving toward intuitive 3D perception—where complex algorithms work beneath a clean, user-friendly surface.

Built-in extensive 2D/3D vision algorithm modules (Mech-Vision)

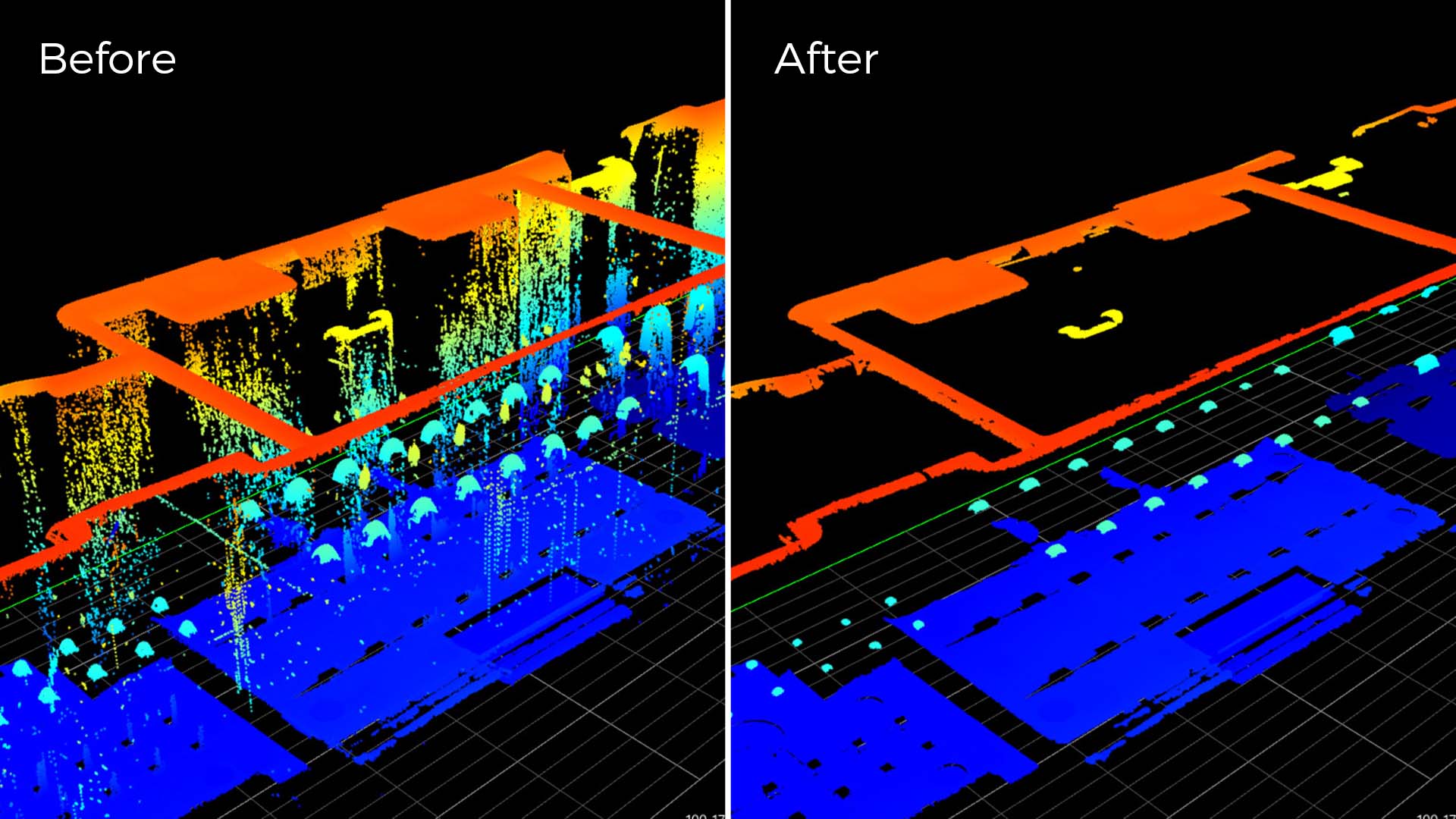

Complementing this is Mech-MSR—an advanced measurement and inspection software that supports multi-sensor networking to generate complete, detailed 3D data. With built-in preprocessing filters and self-developed denoising algorithms, Mech-MSR can effectively handle noise interference caused by blind spots and high reflectivity, significantly improving inspection stability. As factories increasingly demand both speed and traceable accuracy, 3D vision software like Mech-MSR is redefining the standards of quality inspection.

Multiple denoising algorithms remove point clouds’ noise for stable inspections. (Mech-MSR)

From Code to No-Code: Easy and Rapid Deployment

Ease of use has become a decisive factor in the adoption of machine vision. The global shortage of skilled vision engineers has accelerated the move toward low-code or no-code software. Instead of custom scripts, engineers now assemble workflows through drag-and-drop modules or guided templates.

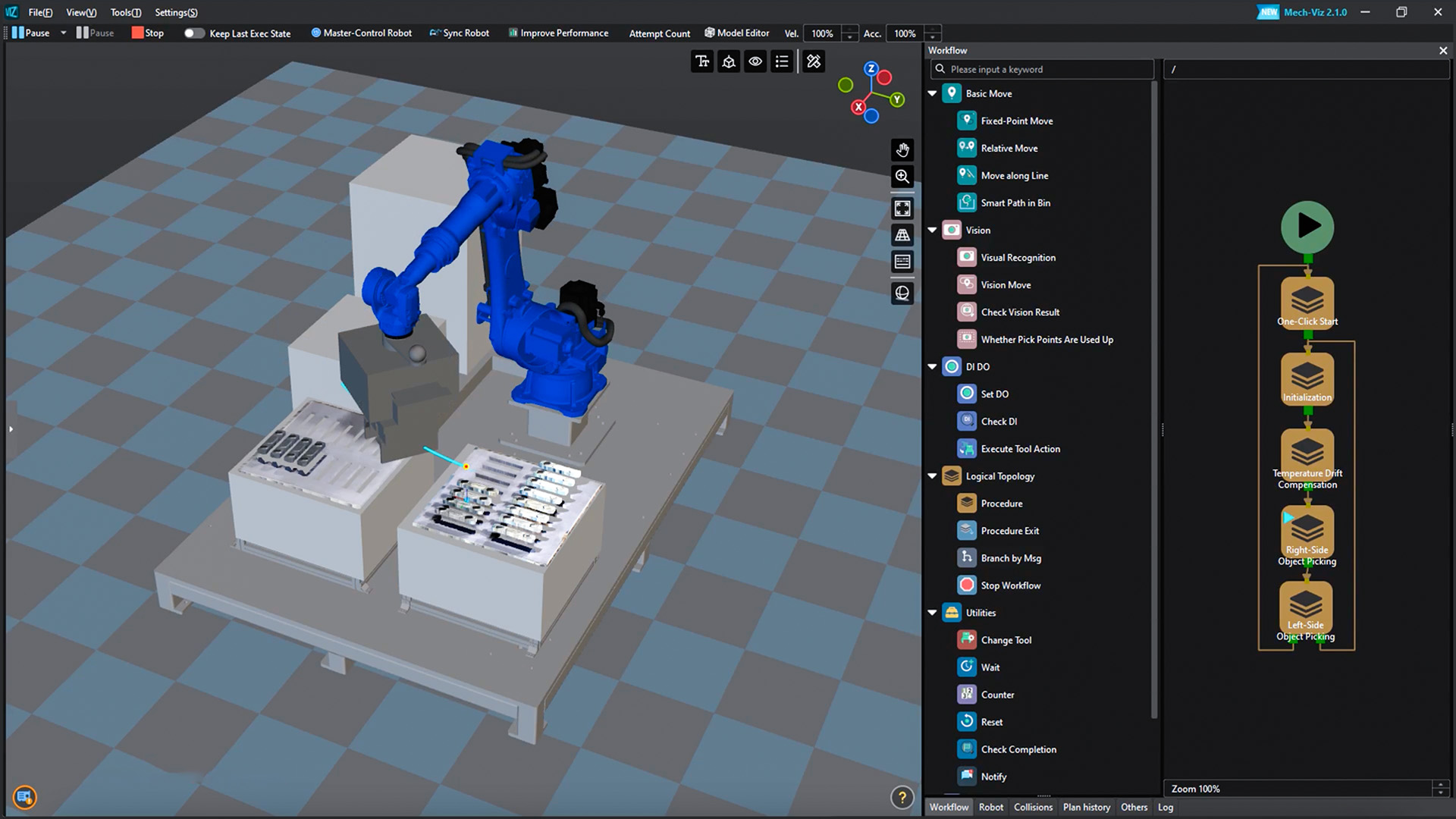

This philosophy lies at the heart of Mech-Mind’s software ecosystem. Mech-Vision’s extensive solution library and Mech-MSR’s all-in-one configuration toolbox enable integrators to set up vision systems in hours rather than weeks. Mech-Viz, a robot programming software, takes this one step further—its flowchart interface and one-click simulation make vision-guided robots simple to deploy and modify. By converging vision and robot control within a unified software layer, Mech-Mind reduces integration complexity and downtime, supporting the industry’s wider move toward flexible, intelligent automation.

Graphical, wizard-style user interface lets non-experts get started easily. (Mech-Viz)

Integrated AI and Robotics: The Path Toward Embodied Intelligence

Beyond individual products, the most transformative trend is the convergence of perception, decision, and execution—the foundation of what researchers call embodied intelligence. In this paradigm, software doesn’t just process images; it guides physical behavior. Robots equipped with multimodal AI can perceive complex environments, understand objectives, and adapt their strategies in real time.

Mech-Mind’s approach reflects this direction. Its unified software stack—spanning Mech-Vision (machine vision), Mech-DLK (deep-learning), Mech-MSR (measurement & inspection), and Mech-Viz (programming)—is designed as the core part of the complete general-purpose robot “Eye-Brain-Hand” framework. Together, they form an adaptive system that learns from both visual data and operational feedback, bridging the gap between perception and execution.

Looking ahead, Mech-GPT, Mech-Mind’s self-developed multimodal large model, extends this architecture even further. It empowers robots with human-like learning, understanding, and reasoning abilities—enabling them to interpret natural language instructions, perceive scenarios through 3D vision, and autonomously perform complex tasks. With Mech-GPT, embodied AI is moving decisively from research into real-world industrial production.

Mech-Mind’s self-developed software suites

Outlook: Software as the Competitive Edge

As manufacturing enters the era of intelligent automation, machine vision software is no longer a supporting tool—it has become a strategic enabler. Future factories will rely on unified platforms that can learn, adapt, and scale across diverse tasks. Success will depend not only on camera resolution or robot precision, but on the software’s ability to fuse multimodal data, understand context, and guide action intelligently.

Within this landscape, Mech-Mind’s focus on AI-driven, 3D vision, and user-friendly software positions it squarely within the industry’s most important trends. Machine vision software has become the brain of automation—and the frontier where robotics, AI, and human ingenuity converge.