Mech-Mind Robotics showcased its all-in-one AI+3D robot solutions for manufacturing, warehousing, and other industrial applications at automatica 2022, June. 21-24, in Munich, Germany.

As the world's leading exhibition for smart automation and robotics, automatica provides an exclusive platform for companies from all relevant branches of industry access to innovations, knowledge, and industry trends with a great deal of business relevance. With a total of 574 exhibitors from 35 countries and the participation of more than 28,000 visitors from around 75 countries, automatica 2022 concluded with great success.

automatica 2022 underlined the importance of automation, robotics, and digitalization as the driver of industry growth. Mech-Mind Robotics, an exhibitor of automatica 2022, shares the same page with automatica and has showcased a full set of innovative robotic solutions for further accelerating industrial automation.

— AI + 3D Robot Solutions Accelerate Industrial Automation —

Live demos from Mech-Mind Robotics have been demonstrated at the 200sqm's booth with highlight applications, including random bin picking, piece picking, palletizing & depalletizing, assembly, localization, guling, etc.

Mech-Mind has shown that industrial robots, combined with 3D vision and advanced artificial intelligence (AI) technologies, pick challenging metal parts from the deep material bin with outstanding flexibility and stability, build stable pallets loaded with mixed SKUs with optimal use of space, precisely remove objects and gently load them at desired destinations, etc.

Highlight Applications

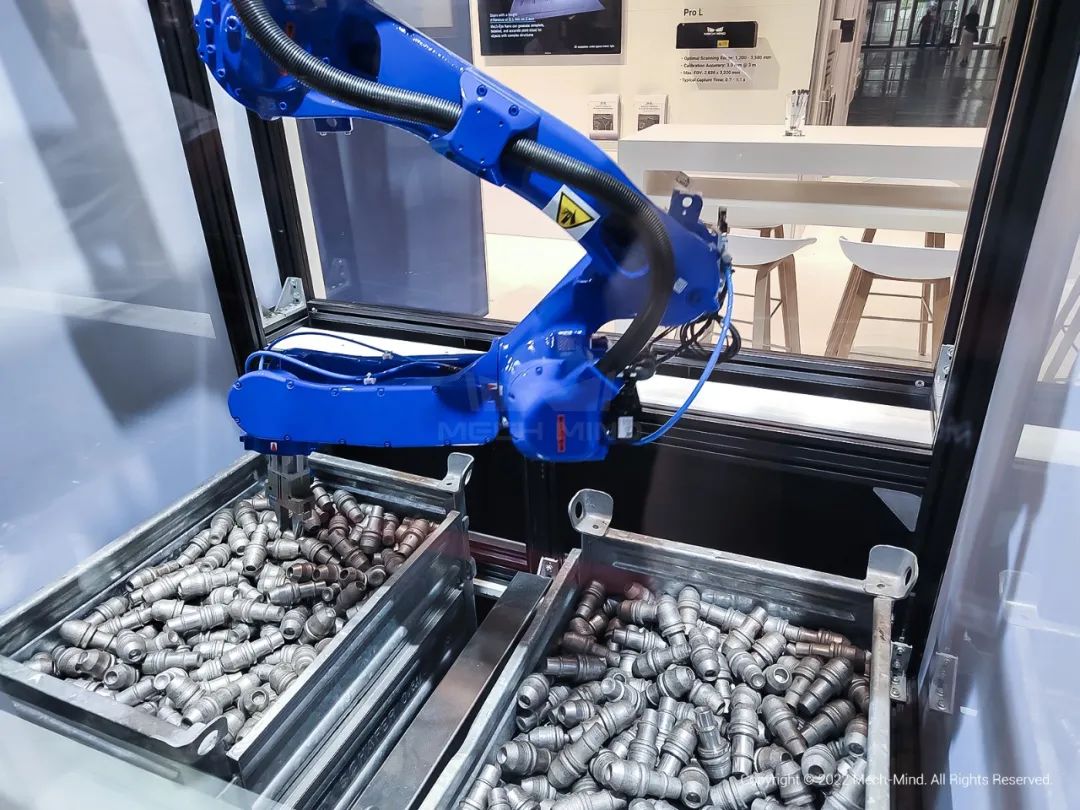

| Vision-Guided Random Bin Picking

- Support small-size, reflective and randomly-stacked workpieces;

- Intelligent algorithm to detect the stacking status of workpieces in real time, and select optimal picking trajectories and angles to empty the material bin with high stability;

- Motion planning and collision detection to ensure high stability and reliability in compact space.

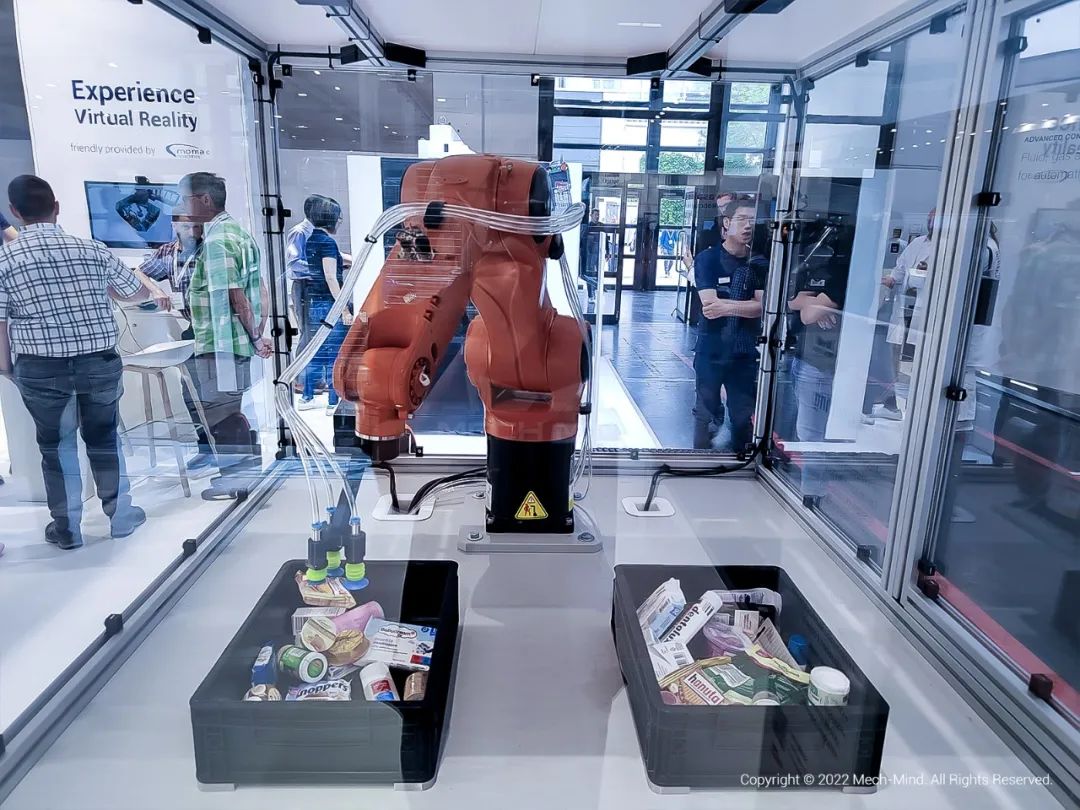

| Vision-Guided Piece Picking of Multi-SKUs

- Support a wide variety of goods, including boxes, bags, small sizes, irregular goods, etc.; easily handle frequent SKU updates;

- Intelligent stacking detection algorithm to avoid mispicks and dropping;

- Intelligent selection of applicable suction cups according to the size of the goods;

- Seamless integration with AGV/AMR, conveyors, WMS systems, and other logistics equipment.

| Vision-Guided Case Palletizing and Depalletizing

- Support randomly-placed or tightly-piled cases;

- Resistant to severe ambient light interference;

- Support cases with cable ties, tapes, patterns, texts, etc. on the surface;

- Intelligent planning of stacking pattern to maximize the use of cage trolley's space;

- Intelligent path planning algorithm to automatically select the optimal trajectory path and entry angle within the limited space, avoiding collision and improving stability.

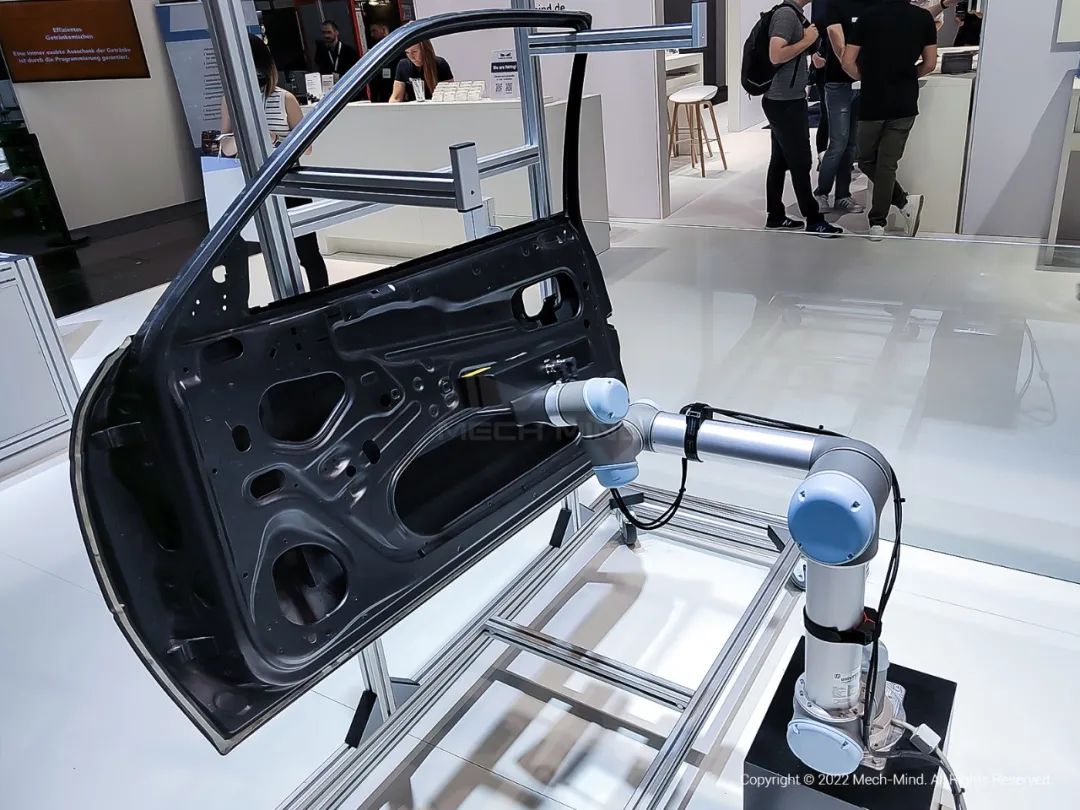

| Vision-Guided Gluing

- Mech-Eye PRO S industrial 3D camera can generate high-quality point cloud data for dark and uneven surfaces of doors and execute high precision door gluing;

- Mech-Eye PRO S is compact and can be loaded on collaborative robotic arms with high flexibility;

- Precise positioning of the door to complete the glue application with outstanding flexibility and reliability;

- No need for high-precision positioning fixture, saving equipment maintenance costs and improving the overall flexibility of the workstation.

| Vision-Guided Localization and Assembly

- Quickly adapt to various types of holes with different sizes and shapes and reflective surfaces;

- Resistant to severe ambient light, guaranteeing stable operation under a certain degree of ambient light interference in the field;

- Mech-Eye NANO is palm-sized and lightweight, and can be loaded on collaborative robotic arms for flexible and fast deployment;

- With Mech-Mind 3D vision system, the robot can locate small holes with high precision and quickly complete assembly.

Mech-Mind's AI+3D robot solutions empower industrial robots with unmatched capacity and flexibility for task variations and complexity that traditional industrial robots struggle to handle.

Plus, Mech-Mind demoed Mech-Eye industrial 3D camera series, which are well-thought-out and industry-ready for warehouse automation, factory-floor applications, and more demanding industrial settings.

— Mech-Mind Team —

Mech-Mind believes intelligent robots can reshape the future of automation. Mech-Mind will continuously develop more powerful 3D vision products and robotic innovations to bring industrial automation to the next level.

Mech-Mind Germany, with a whole team of sales, presales, engineers, and project managers in Munich, is dedicated to delivering more viable solutions and comprehensive service for partners and customers from Europe and other regions. If you have any inquiries, don't hesitate to get in touch with us at: info@mech-mind.net.