Recently, Mech-Mind has released a major upgrade to Mech-MSR 3D Measurement and Inspection Software. The new version of Mech-MSR features a 100% graphical, wizard user-interface, enabling users to rapidly deploy a wide range of 2D/3D quality-inspection applications. The software also integrates a suite of advanced AI algorithms and robust tools to help customers enhance quality-inspection precision and efficiency.

Newly upgraded Mech-MSR supports both the Mech-Eye 3D Laser Profilers and the Mech-Eye Industrial 3D Cameras, enabling rapid calibration with multi-sensor networking—including side-by-side, reverse, opposite, and angled layouts—so users can complete end-to-end, one-stop deployments of diverse quality-inspection applications.

Today, Mech-MSR is widely deployed across electronics, EV battery, automotive, photovoltaic, and more industries, significantly enhancing production efficiency and decision-making precision to empower intelligent manufacturing.

01 Intuitive Interface & Convenient AI Tuning Tools

Accelerating Deployment Efficiency

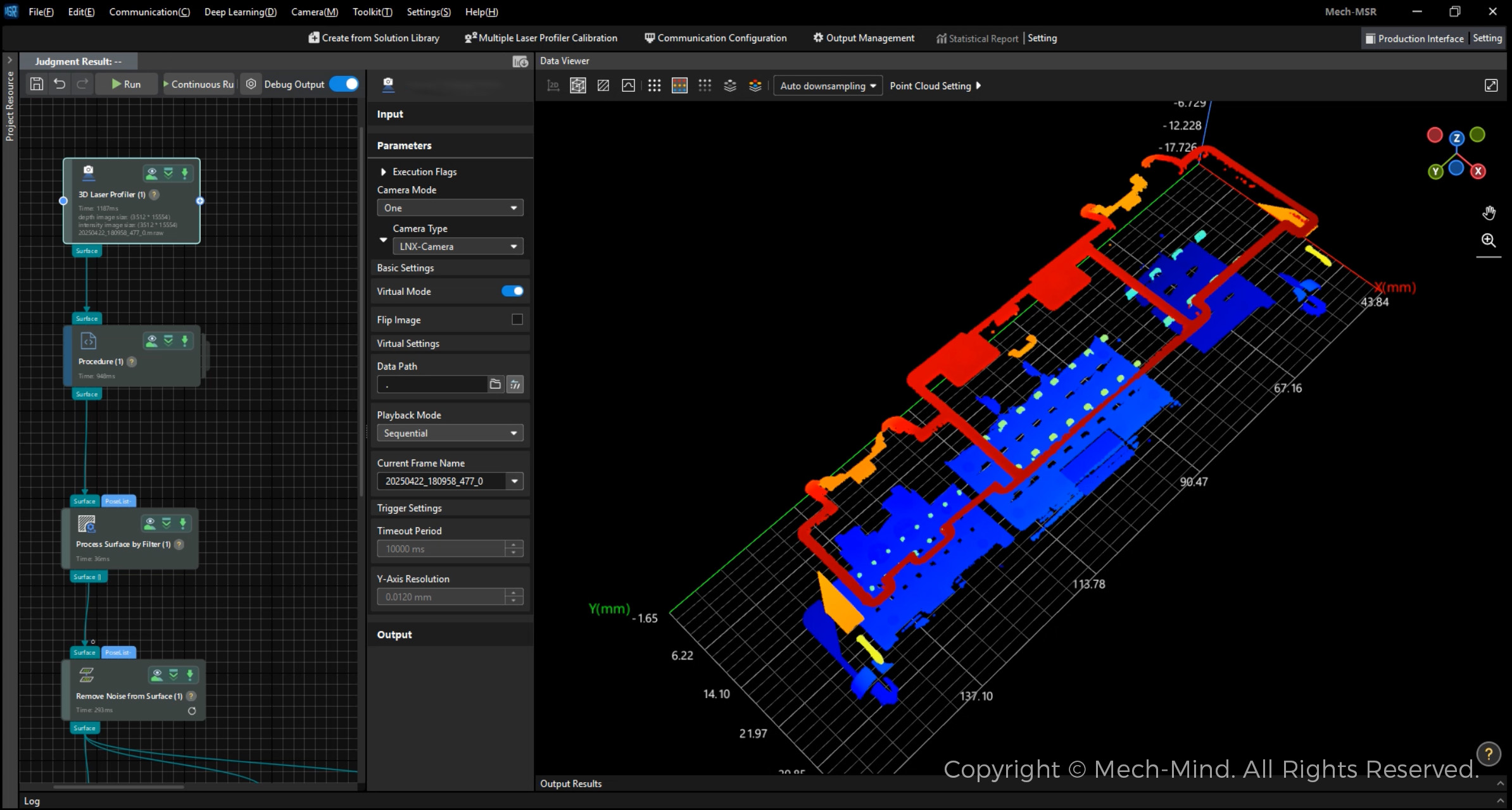

Mech-MSR graphical user-interface

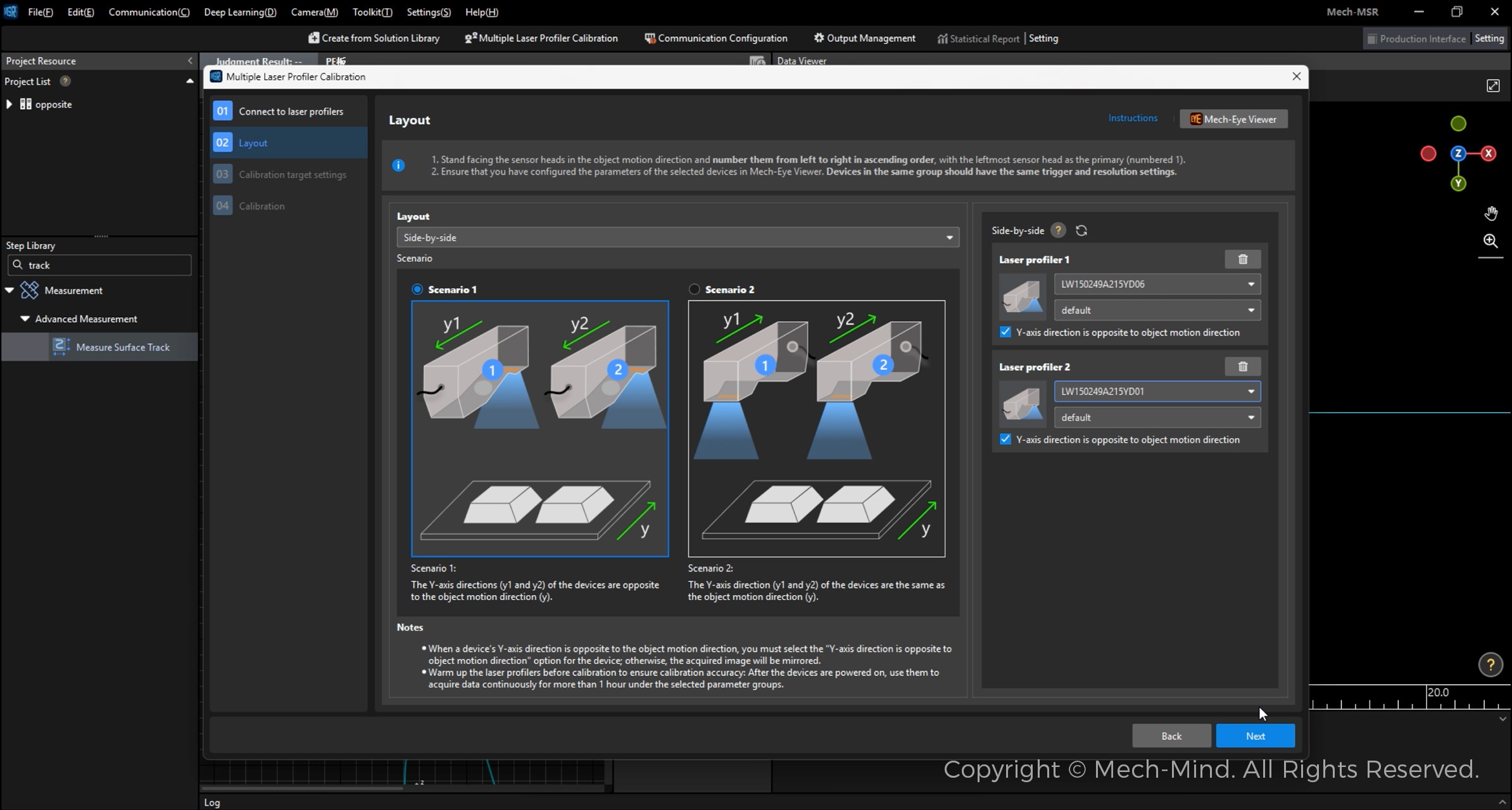

Multi-sensor networking

Mech-MSR’s fully graphical, wizard user-interface guides users step by step through all required operations, enabling rapid deployment of quality-inspection applications with minimal technical learning.

Multiple Mech-Eye 3D Laser Profilers can be calibrated in seconds with side-by-side, reverse, opposite, or angled layouts, providing an expanded FOV (field of view) with multiple viewing angles for complete and precise imaging in complex production scenarios.

The software also offers a range of built-in AI tuning tools—such as the deviation-analysis against CAD-model, glue-bead inspection and matching-model editing—along with a library of typical application solutions to help users get started instantly.

Deviation Analysis Against CAD Model: Supports full-data comparison between input images and CAD files, delivering intuitive and precise analysis of subtle part deviations.

Glue Bead Inspection: Configures complex glue bead track line rapidly—measuring length, width, height, cross-sectional area, etc., in a single step.

Matching Model Editing: Customizes matching models and quickly adjusts model features, achieving sub-pixel data alignment and accurate locating.

02 Extensive and Robust AI Algorithms

Tackling Complex Quality-Inspection Scenarios Efficiently

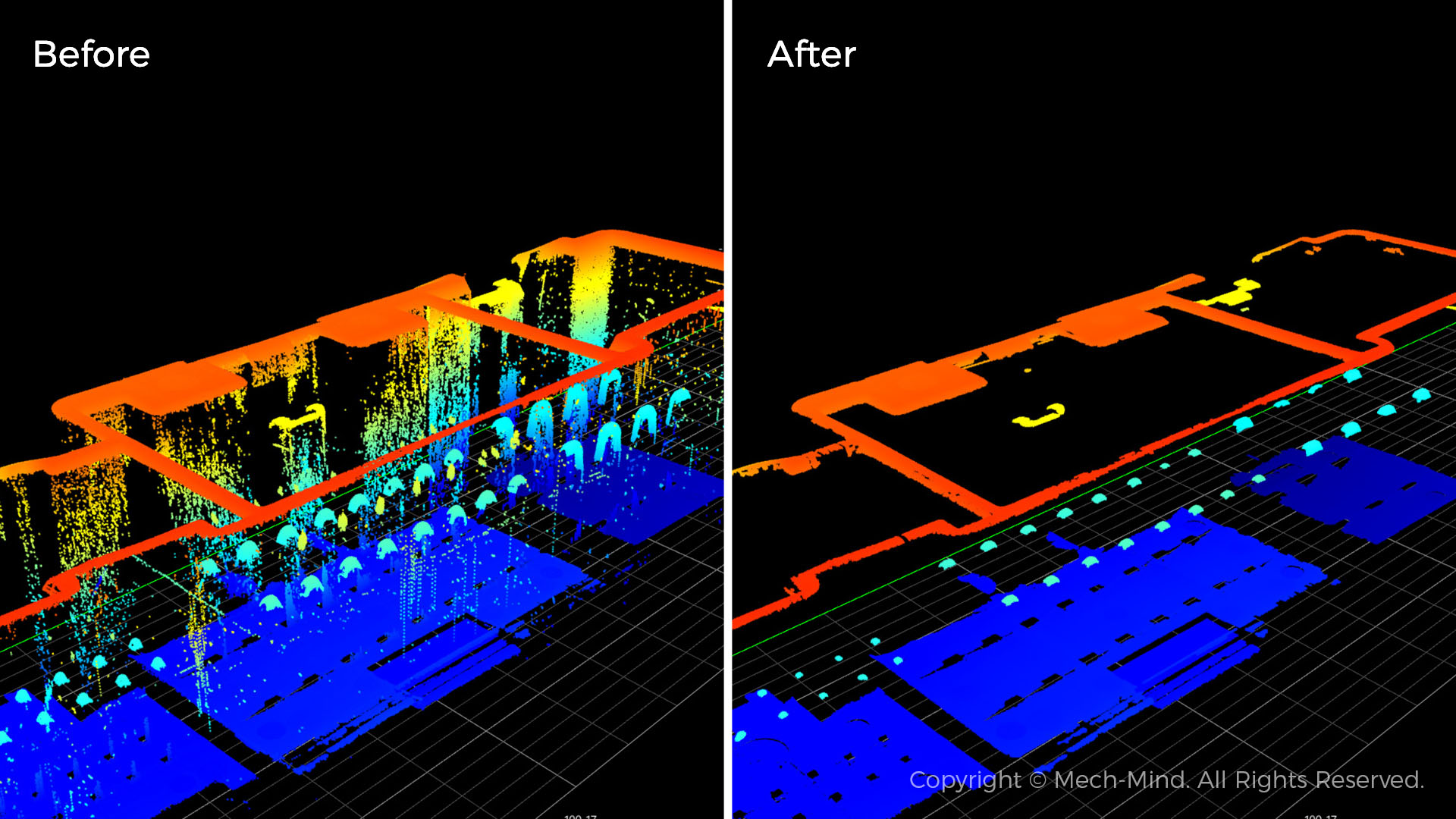

Intelligent denoising algorithms remove up to 99% of noise

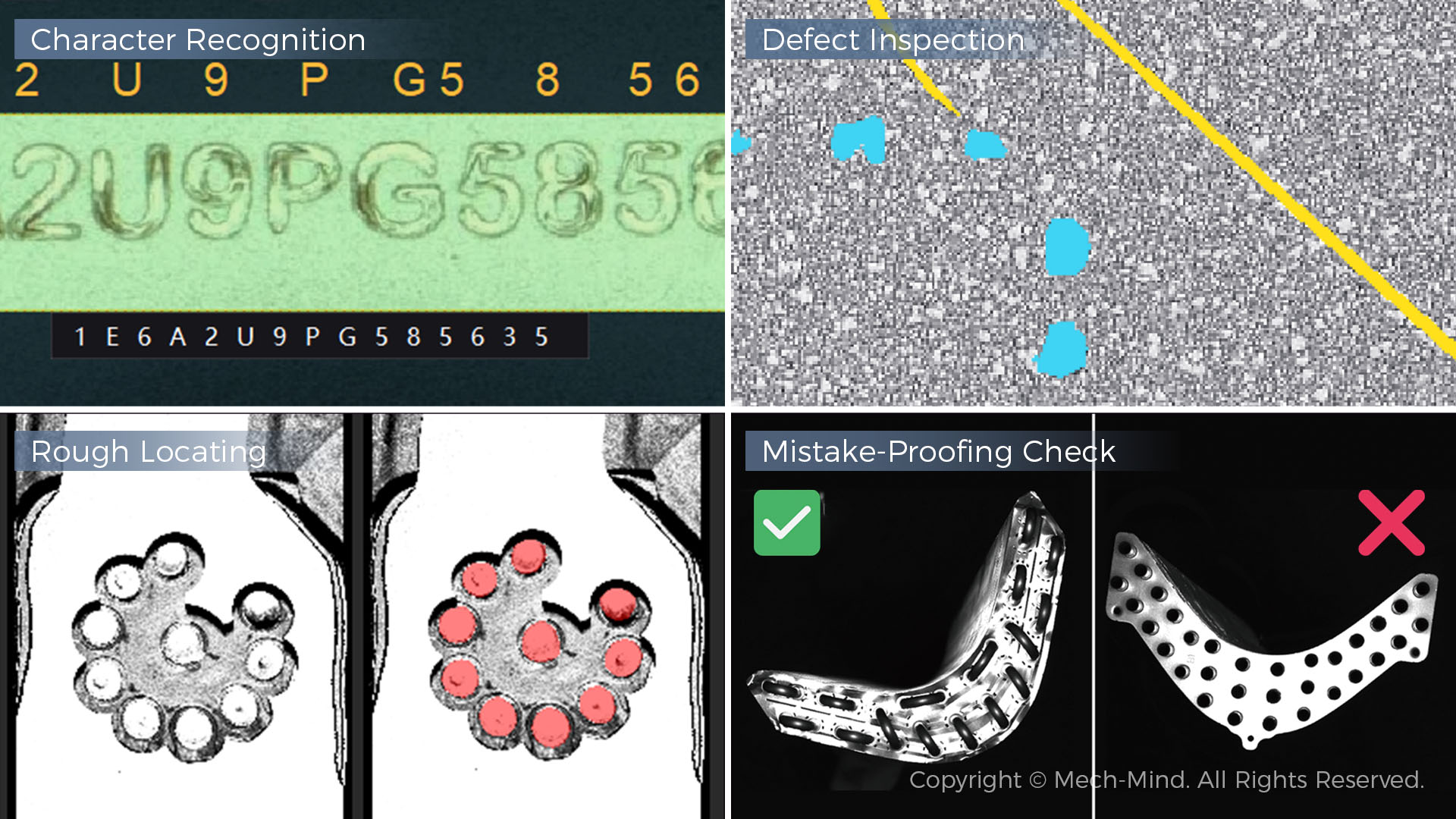

Deep learning-powered quality inspection functions

Mech-Eye LNX 3D laser profilers can accurately image object shapes and subtle features. For 3D data obtained by the sensors, Mech-MSR provides a suite of preprocessing filters and high-precision denoising algorithms to effectively address noise interference in complex scenarios (e.g., blind spots, high reflectivity), thereby providing reliable data support for high-precision measurement and inspection.

With one-click import of Mech-DLK trained model packages, users can deploy end-to-end, deep-learning-based quality inspection applications. Leveraging robust deep learning algorithms, Mech-MSR effectively addresses challenging situations—such as high reflectivity, variable shapes, and subtle features—to achieve reliable measurement and inspection in various complex scenarios.

03 Versatile 2D/3D Measurement & Inspection Functions

Enabling One-Stop Deployment

Supports multiple 2D/3D quality inspection applications

Versatile functions for end-to-end deployment

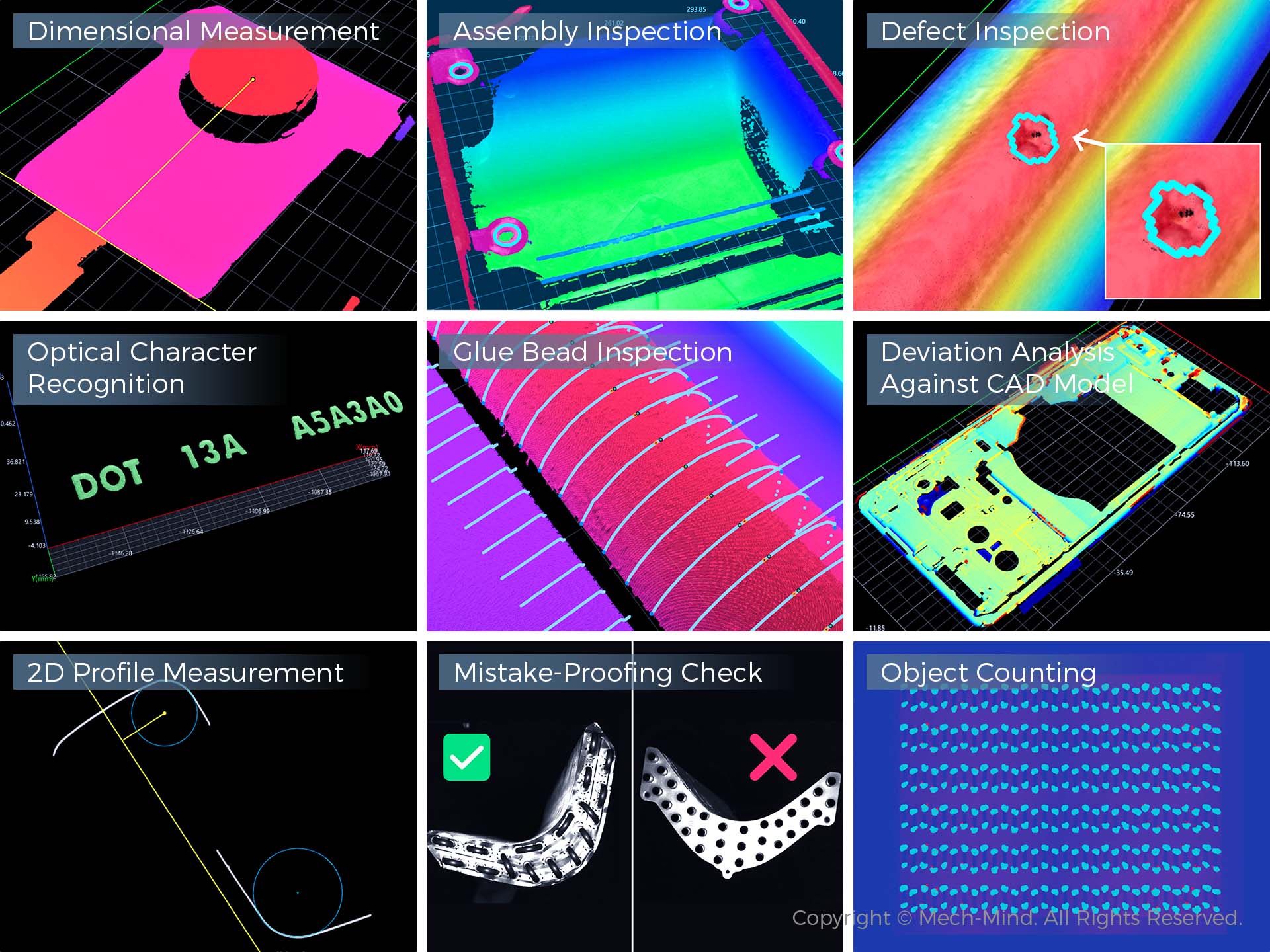

This upgrade adds 2D inspection functions—such as dimensional measurement, geometric measurement, and defect inspection—alongside new 3D measurement functions like glue bead inspection and assembly inspection, better meeting the needs for comprehensive quality-inspection in real-world production.

Mech-MSR supports both Mech-Eye 3D laser and structured-light sensors, enabling one-stop processing of typical 2D/3D measurement and inspection tasks with a single software—significantly reducing both deployment complexity and cost.

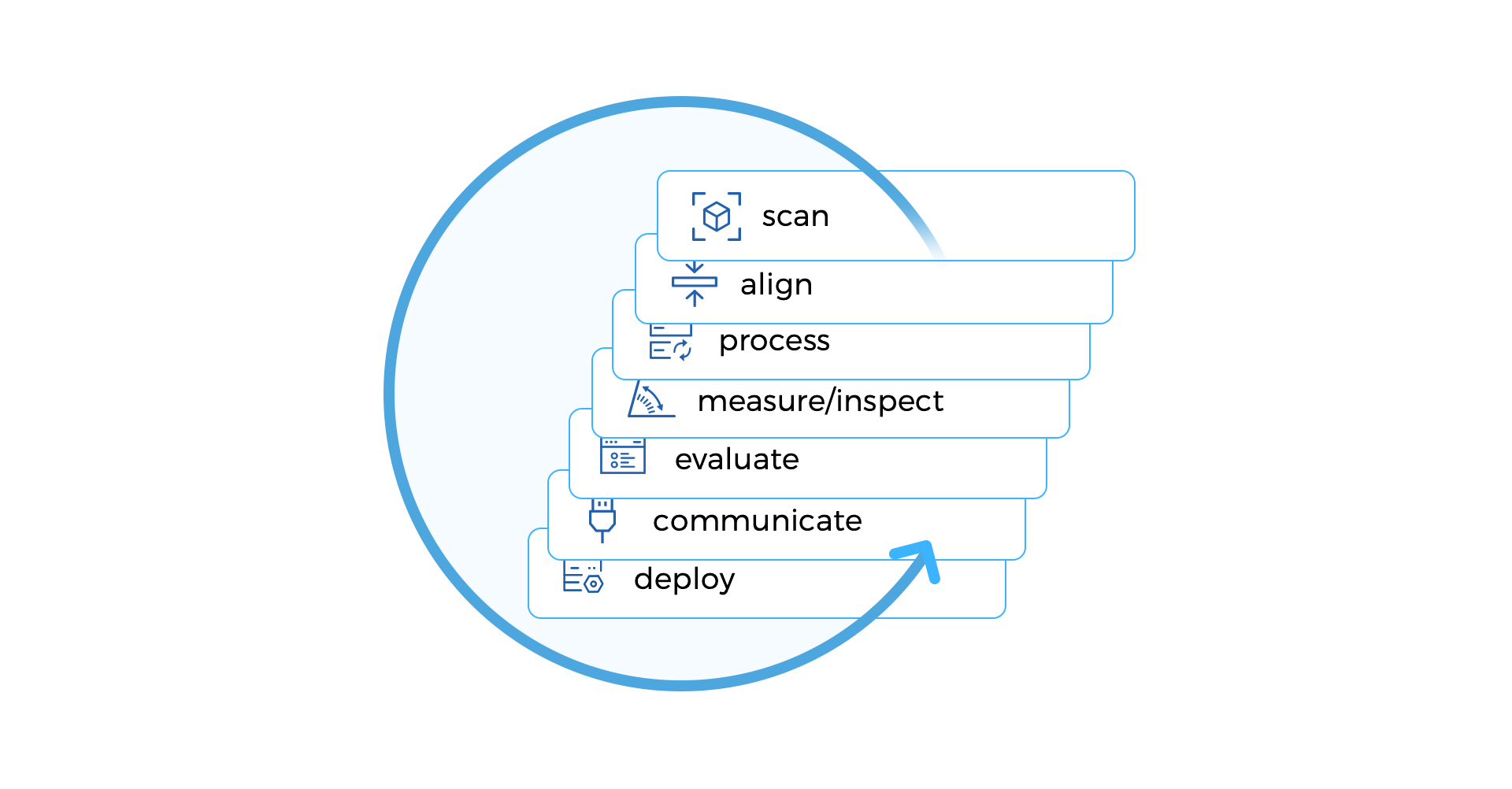

The software provides versatile functions including scanning, alignment, processing, 2D/3D measurement & inspection, evaluation, communication, etc.—supporting end-to-end, one-stop deployments.

04 Flexible Compatibility & Comprehensive Connectivity

Empowering Quality Decision-Making and Process Optimization

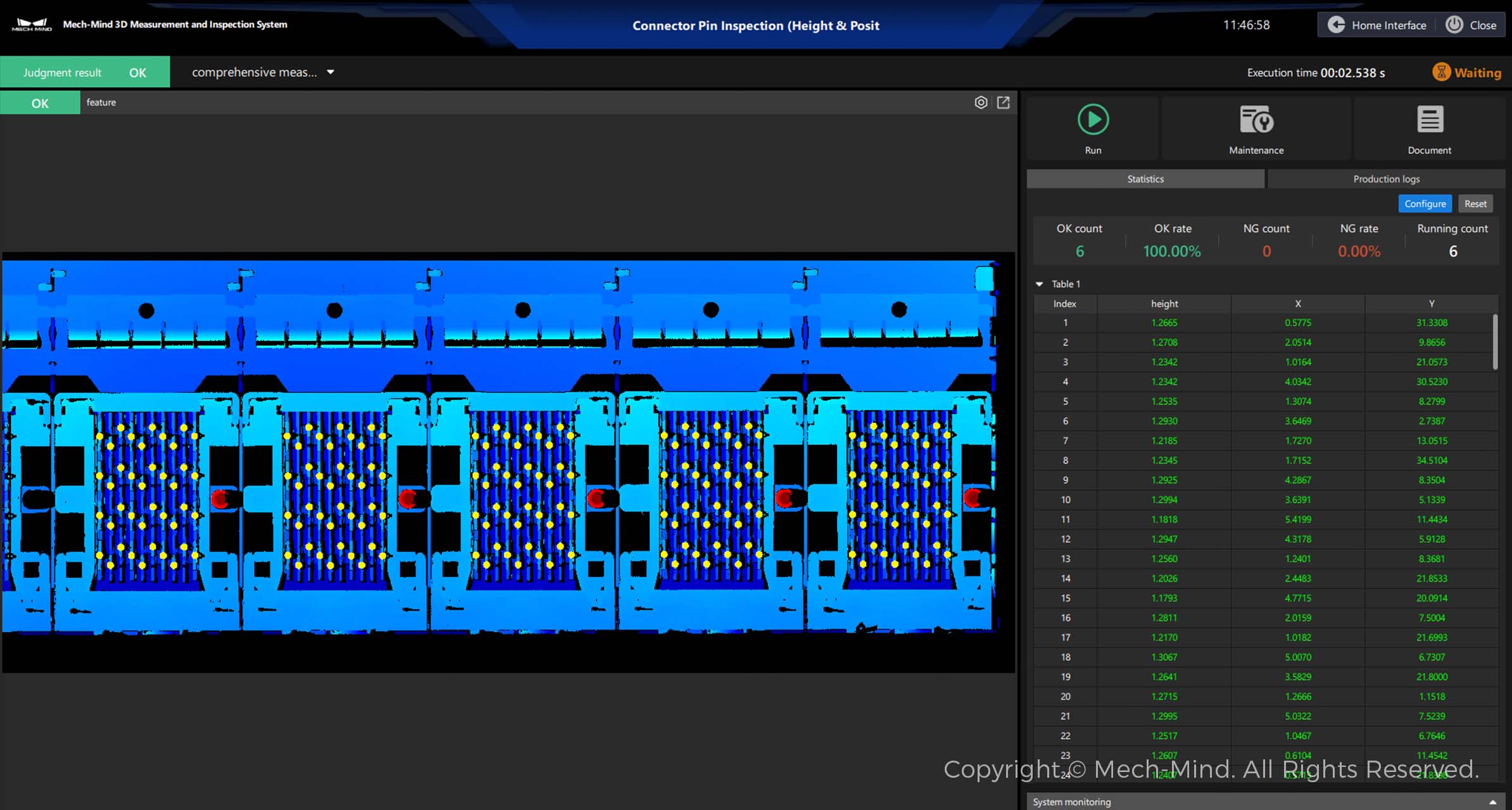

Production interface

The seamless integration of Mech-Eye LNX 3D Laser Profilers with Mech-MSR delivers best-in-class industrial adaptability, effortlessly connecting with diverse factory equipment. It supports multiple project-trigger and result-evaluation methods to meet complex industrial requirements.

Mech-MSR provides correlation compensation and result-evaluation tools to ensure measurement results reliably meet customers’ process standards. Real-time storage and in-depth analysis of measurement data support querying, analysis, statistics, and execution failures alerts, facilitating process optimization and ensuring manufacturing stability.

The production interface of Mech-MSR features a modular design with visual data interaction, intuitively displaying key data such as throughput, cycle time, measured values, and inspection results, offering effective support for production decisions and process improvement.

05 Comprehensive Documentation & Technical Support

Ensuring Rapid Response & Expert Service

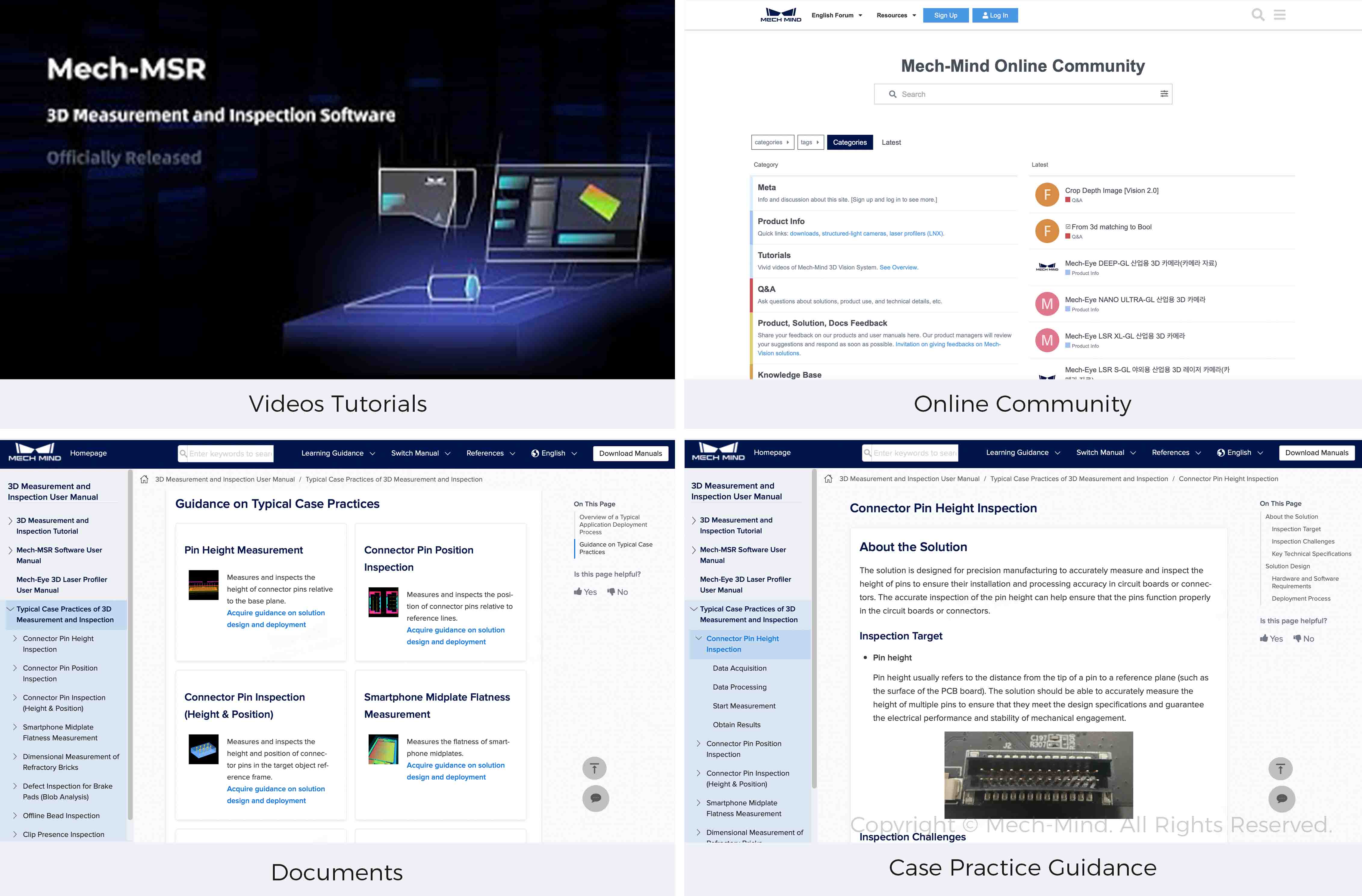

Robust technical support for faster, more reliable deployment

Mech-Mind provides extensive, easily accessible technical materials such as case-practice guidance, technical documents via the online community, documents and official website—enabling users to quickly resolve on-site issues.

From requirement assessment and solution design to on-site tuning and maintenance, Mech-Mind delivers technical support services covering the entire project lifecycle to ensure rapid deployment and sustained, stable operation of diverse applications.

Mech-MSR features intuitive interfaces, robust AI algorithms, and comprehensive technical support, empowering partners to deploy 2D/3D measurement and inspection applications more efficiently and conveniently. What’s more, Mech-Mind continues to enhance the performance and expand the model range of the Mech-Eye LNX 3D Laser Profilers, addressing diverse requirements for FOV, accuracy, and cycle time across different scenarios, helping customers in automotive, electronics, EV battery, photovoltaic, and other industries improve product quality and overall production efficiency.

For more information on Mech-Mind's products and services, feel free to contact us via:

Business: info@mech-mind.net

Marketing/PR: marketing@mech-mind.net